ASTM A36 steel is one of the most widely used carbon steel grades in the world. It is a standard specification set by the American Society for Testing and Materials (ASTM) that defines the chemical composition, mechanical properties, and applications of mild carbon steel. Known for its strength, weldability, and cost-efficiency, ASTM A36 has become the go-to choice in structural engineering, machinery fabrication, and infrastructure projects.

ASTM A36 Steel Overview

The ASTM A36 standard covers carbon structural steel used in the construction of bridges, buildings, and general structural purposes. It is ideal for both welded and bolted connections and can be hot-rolled into various shapes such as plates, bars, angles, and beams.

As a low-carbon steel grade, ASTM A36 offers a balance between strength and ductility, making it suitable for applications that require moderate load-bearing capacity and easy fabrication. This balance is what makes A36 such a popular option in industries worldwide—from construction and shipbuilding to energy and manufacturing.

Importance of ASTM Standards

ASTM standards ensure consistency and reliability across the global steel supply chain. By defining clear requirements for composition, strength, and testing, these standards help engineers and manufacturers achieve predictable performance in critical applications. ASTM A36 is one of the foundational standards within the ASTM A series, serving as a benchmark for other structural steel grades.

Chemical Composition and Material Specification

The chemical composition of ASTM A36 plays a critical role in determining its mechanical behavior. It includes carbon, manganese, phosphorus, sulfur, and silicon—each contributing to the steel’s final performance characteristics.

Chemical Elements and Their Roles

- Carbon (C): The primary hardening element that increases tensile strength while slightly reducing ductility. ASTM A36 has a carbon content typically below 0.29%.

- Manganese (Mn): Enhances toughness and reduces brittleness, typically between 0.80–1.20%.

- Phosphorus (P): Present in minimal quantities to avoid brittleness (≤ 0.04%).

- Sulfur (S): Controlled to ≤ 0.05% to maintain toughness and improve machinability.

- Silicon (Si): Adds elasticity and aids in deoxidizing molten steel during production.

Standard Chemical Composition Table

| Element | Composition (%) | Function |

|---|---|---|

| Carbon (C) | 0.25–0.29 | Provides strength and hardness |

| Manganese (Mn) | 0.80–1.20 | Improves toughness and ductility |

| Phosphorus (P) | ≤ 0.04 | Reduces brittleness |

| Sulfur (S) | ≤ 0.05 | Enhances machinability |

| Silicon (Si) | ≤ 0.40 | Improves elasticity and formability |

Mechanical Properties of ASTM A36 Steel

The performance of ASTM A36 is defined not just by its composition but by its mechanical properties—the measurable characteristics that determine how the steel behaves under stress, load, and temperature variations.

Key Mechanical Strength Parameters

- Tensile Strength: 400–550 MPa

- Yield Strength: Minimum 250 MPa

- Elongation: 20% (minimum in 200 mm gauge length)

- Brinell Hardness: Approximately 119–162 HB

These properties allow ASTM A36 to maintain structural integrity while offering flexibility in design and fabrication. The combination of moderate strength and excellent formability makes it suitable for bending, cutting, and welding operations.

Performance Comparison with Other Carbon Steels

When compared to other grades such as ASTM A283 or ASTM A572, A36 falls into the mild to medium strength range. While higher grades offer greater tensile strength, A36 remains more versatile due to its cost efficiency and ease of processing. It is often selected for non-critical structures or applications where weight and cost efficiency are key.

Weldability, Machinability, and Formability

One of the most notable benefits of ASTM A36 steel is its weldability. It can be easily joined by conventional methods including MIG, TIG, and arc welding without the need for preheating. The low carbon content minimizes cracking risk in heat-affected zones, ensuring strong joints and durability.

Its machinability is rated at approximately 72% compared to AISI 1112, and the material can be readily cut, drilled, and shaped. In terms of formability, A36 exhibits excellent performance during bending and rolling, allowing engineers to create complex profiles and assemblies with ease.

Manufacturing and Processing Standards

ASTM A36 steel is typically produced through hot-rolling, ensuring consistency in mechanical strength and grain structure. Depending on the end-use, manufacturers may apply additional treatments or surface finishes to enhance corrosion resistance and appearance.

ASTM A36 Steel Production Methods

The steel is melted and refined in an oxygen or electric furnace to remove impurities. It is then hot-rolled into various shapes such as plates, beams, and channels under strict quality control standards. During rolling, temperature control ensures uniform grain structure and mechanical stability.

Surface Finishing and Heat Treatment Options

ASTM A36 can undergo several surface and thermal processes, including:

- Pickling and Oiling: To prevent oxidation during storage and shipping.

- Galvanizing: Adds a protective zinc layer for corrosion resistance.

- Normalizing: Enhances toughness and refines the grain structure.

- Stress Relieving: Reduces internal stress after welding or forming.

Forms and Dimensions Available

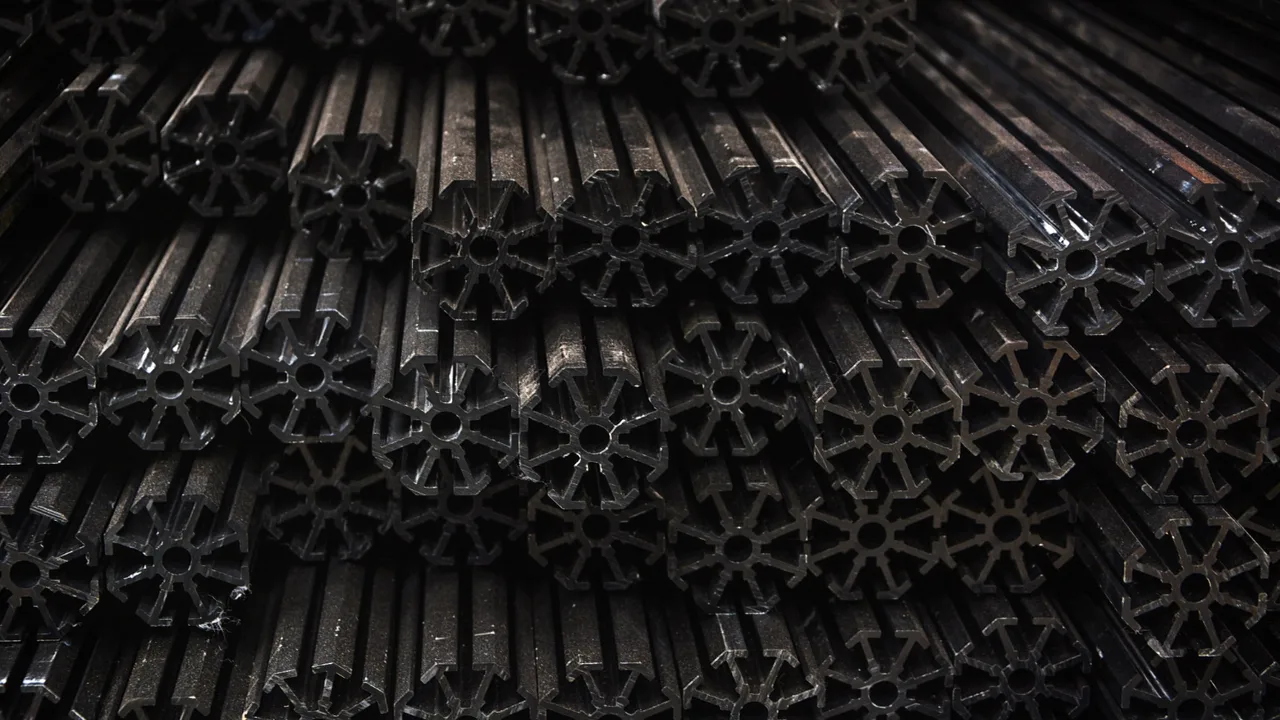

Manufacturers produce ASTM A36 in numerous forms to meet diverse project requirements:

- Plates and Sheets (up to 150 mm thick)

- Beams and Channels (standard I, H, C, and U sections)

- Angles and Flats for trusses, frames, and supports

- Bars and Rods for machining and fabrication

Dimensional tolerances conform to ASTM A6/A6M, ensuring compatibility with various construction and industrial applications.

Applications of ASTM A36 in Modern Industries

Thanks to its balanced mechanical and chemical characteristics, ASTM A36 is a fundamental material in countless engineering and industrial sectors. Its versatility, affordability, and global availability make it one of the cornerstones of modern infrastructure.

Construction and Infrastructure

In the construction sector, ASTM A36 is used extensively in structural frameworks—columns, beams, girders, and trusses—where moderate strength and high weldability are required. From warehouses and bridges to skyscrapers and stadiums, it provides reliable performance at an economical cost.

Machinery and Fabrication

ASTM A36 is widely used in fabricating machine bases, frames, platforms, and supports due to its excellent machinability. The steel’s consistent performance simplifies cutting, shaping, and joining, allowing engineers to build precise industrial equipment with long service life.

Shipbuilding and Automotive Uses

In the shipbuilding industry, ASTM A36 steel is often used for low-stress structural components such as hull frames, deck supports, and bulkheads. Its formability and weldability make it suitable for curved and contoured ship sections that require reliable load-bearing without excessive weight. In automotive applications, A36 finds use in frames, chassis brackets, and mounting structures where moderate strength and cost efficiency are desired.

Energy and Industrial Plants

Within energy facilities and industrial plants, A36 is used for support platforms, conveyor structures, piping racks, and tank foundations. The steel’s adaptability to both welded and bolted joints allows quick assembly on site, which is critical for large-scale industrial installations. Its predictable mechanical behavior ensures safety and stability under operational loads.

Advantages and Limitations of ASTM A36 Steel

Advantages

- Cost-Effective: Compared to higher-grade alloys, A36 provides dependable strength at a lower price point, making it ideal for mass construction and fabrication.

- Excellent Weldability: Low carbon content enables easy welding without preheating or special filler metals.

- Good Ductility: The steel can deform without cracking, which is useful for forming, bending, or rolling complex shapes.

- Versatile Availability: Supplied worldwide in plates, bars, and structural sections, ensuring compatibility with existing fabrication systems.

Limitations

- Lower Strength Range: For high-load or critical applications, stronger grades such as ASTM A572 Gr.50 may be preferable.

- Moderate Corrosion Resistance: Without protective coatings, A36 may rust in humid or marine environments.

- Temperature Sensitivity: Not recommended for use at very low or high temperatures where brittleness or creep could occur.

Comparison with Similar Standards and Grades

While ASTM A36 dominates the North American market, other regions have their own equivalents that perform similarly under structural applications. Understanding these equivalencies helps engineers select materials in international projects.

ASTM A36 vs ASTM A572

ASTM A572 Grade 50 offers higher tensile and yield strengths than A36, allowing for lighter sections and reduced weight in structures. However, A36 remains easier to weld and more economical for general use.

ASTM A36 vs EN S235JR

European standard S235JR under EN 10025 has nearly identical properties to A36. Both share similar chemical composition and mechanical strength, enabling interchangeable use in many cases.

ASTM A36 vs JIS SS400

In Japan and parts of Asia, SS400 is considered the counterpart to A36. The two grades match closely in yield strength and chemical balance, making them mutually substitutable for fabrication and export projects.

Global Equivalents Table

| Standard | Equivalent Grade | Region |

|---|---|---|

| ASTM A36 | S235JR | Europe |

| ASTM A36 | SS400 | Japan |

| ASTM A36 | Q235B | China |

Quality Testing and Certification

Standard Testing Methods

Every batch of ASTM A36 steel undergoes comprehensive testing to confirm compliance with ASTM A36/A36M. Typical tests include:

- Tensile Testing: Determines yield and tensile strength values.

- Hardness Testing: Ensures consistent mechanical performance across sections.

- Impact Testing: Measures energy absorption at various temperatures for safety-critical components.

Material Certification and Traceability

Reputable suppliers provide mill test certificates (MTCs) documenting chemical and mechanical results. Traceability numbers link each product to its production batch, giving engineers confidence in the steel’s origin and conformity.

Storage, Handling, and Maintenance

Best Practices for Storage

To maintain quality, A36 steel should be stored on elevated racks away from direct moisture. Covering materials with waterproof sheets prevents rust formation. Proper ventilation between stacked plates helps avoid condensation.

Maintenance and Corrosion Protection

When used outdoors or in marine environments, protective coatings are essential. Common approaches include:

- Hot-Dip Galvanizing: A zinc layer that provides sacrificial protection against corrosion.

- Epoxy or Polyurethane Paints: Effective for bridges, tanks, and exposed structures.

- Regular Inspections: Checking weld joints and fasteners for rust or fatigue damage ensures long service life.

Sustainability and Recyclability

Steel, including ASTM A36, is one of the most recyclable materials on the planet. Its production today increasingly relies on electric-arc furnaces (EAFs) that melt scrap metal, significantly lowering CO₂ emissions. At the end of its lifecycle, A36 can be completely recycled without degradation in quality, aligning with global sustainability goals and green-building standards.

Choosing ASTM A36 for Your Project

When selecting structural steel, engineers evaluate several factors—load requirements, environmental exposure, fabrication methods, and budget. ASTM A36 remains a first-choice material for general applications where cost efficiency, availability, and reliability matter more than extreme performance.

For complex steel-structure projects that demand custom fabrication, precise welding, or large-scale assembly, partnering with a specialized supplier like XTD Steel Structure ensures optimized design, accurate detailing, and strict quality control from production to installation.

Conclusion

ASTM A36 steel continues to play a pivotal role in global engineering. Its well-balanced combination of mechanical strength, affordability, and fabrication ease makes it indispensable across construction, manufacturing, and energy industries. Whether used in bridges, warehouses, or machinery frames, A36 represents a reliable foundation for modern infrastructure and sustainable development.

By understanding its composition, properties, and performance characteristics, engineers and project owners can confidently utilize ASTM A36 to achieve both structural integrity and cost efficiency—solidifying its status as one of the most trusted materials in the steel world.