We’re committed to delivering exceptional results, one project at a time.

Suzhou Wujiang XTD Steel Structure Engineering Co., Ltd. is a one-stop prefab steel structure manufacturer that integrates professional design, processing, installation, and management. Our tailored modular steel building systems include standard portal rigid frames, truss structures, frame structures, bridges, and more. These made-to-measure structural steel solutions apply to a wide range of settings, including airports, exhibition centers, shopping malls, skyscrapers, train stations, gas stations, steel structure warehouse, steel structure factory, steel structure workshop and many more, offering full-scale solutions for every special requirement.

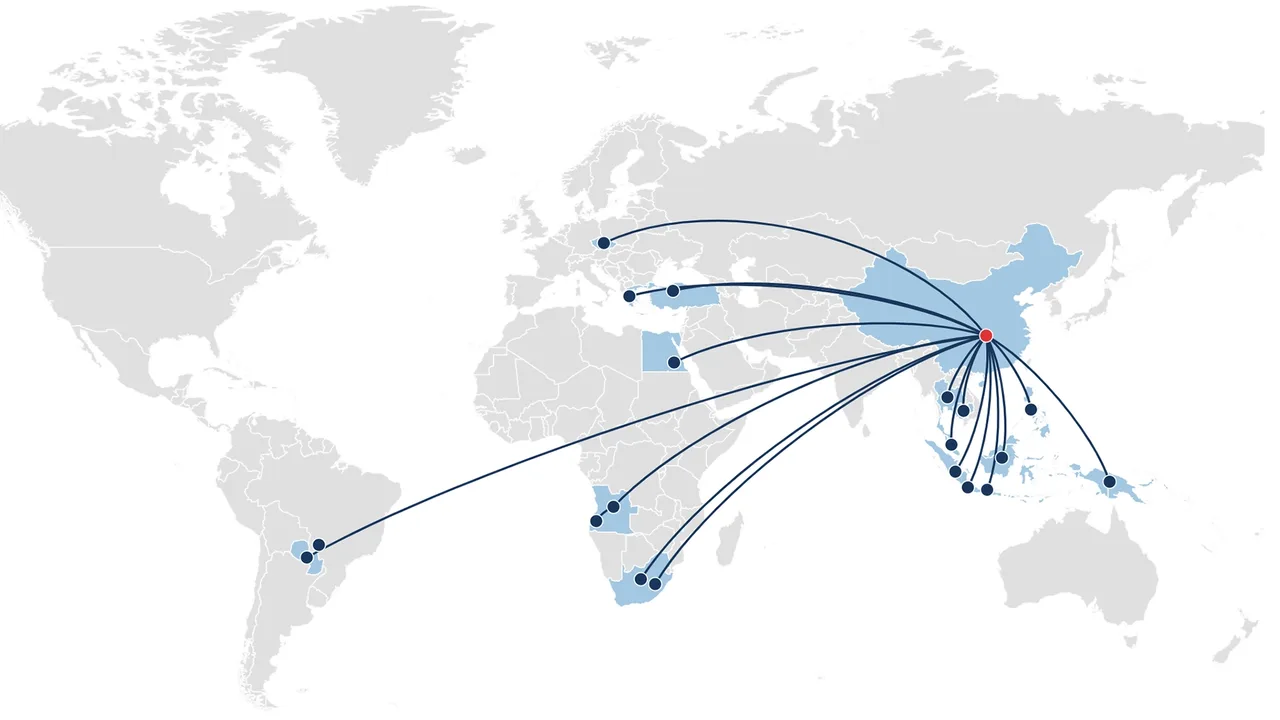

The world map showcases XTD Steel Structure’s international projects, spanning from Papua New Guinea to Greece, reflecting our strong global presence in steel structure engineering and construction. Each location represents a successful collaboration delivering durable, high-quality steel buildings tailored to local needs and international standards. From factories and warehouses to office complexes and industrial facilities, XTD Steel structure compnay continues to expand its reputation as a trusted provider of innovative steel structure solutions across continents.

Steel structures play an important role in modern construction. Modular steel structures from XTD Steel are built with high-strength, corrosion-resistant materials, making them durable even in harsh weather. They also provide design flexibility and customization to suit different project needs, making them a smart and profitable investment. Whether it’s an airport terminal, exhibition center, factory, or gas station, you can rely on this steel structure company.

As an industry-leading full-process prefab steel building manufacturer, XTD Steel Structure has ploughed deeply into the field of transportation technology facilities for more than 20 years. Relying on the high-performance characteristics of Q355B S355JR A572 SM490A grade high-strength steel, coupled with continuous technological innovation, XTD Steel Structure reconstructs the space of the aviation hubs and provides global customers with a modernized terminal building system that integrates high efficiency and intelligent green building, from the design of the steel structure, processing, manufacturing, construction, to the subsequent maintenance during the use of the building. We create a modernized terminal building system that is highly efficient, intelligent, and green.

In the global exhibition center construction sector, steel structures have emerged as the industry’s preferred solution. As an exhibition center owner, you may currently face the following challenges: traditional concrete buildings typically require 1-2 years of construction time, while pre-booked international convention center might commence as early as next year. You need to strictly control construction budgets while achieving large-span column-free spaces to enhance venue utilization and commercial value. Furthermore, exhibition centers must comply with increasingly stringent green building standards. Steel structure exhibition centers represent the optimal solution to address these pain points. XTD Steel Structure, as a global leader in comprehensive steel construction solutions, delivers modern exhibition center solutions integrating large spans, high flexibility, sustainability, and intelligent features for clients worldwide.

XTD Steel Structure is a prefabricated steel building manufacturer in the field of modular construction, focusing on providing global customers with full-scenario solutions ranging from 30X50 single-story steel factories to multi-story mega plants stretching over several kilometers. With more than 20 years of deep cultivation in the industry, we have successfully delivered thousands of factories and infrastructures, with a cumulative plant construction area of nearly 10 million square meters, setting a benchmark in the field of steel structure construction.

As an innovative leader in the field of global steel structure engineering, XTD Steel Structure gathers the industry’s top R&D team to study the special usage scenarios and functional requirements of gas stations in depth, and customizes high-performance and cost-effective prefabricated steel structure gas station solutions for global customers. The steel structure building adopts a modular design concept, which can split the gas station into several standardized and fast-assembling functional modules, which not only significantly shortens the on-site construction period but also effectively reduces the impact of construction on the surrounding environment.

An architectural and development plan is nothing without strong steel structures, especially if you want to build an impactful project. You can start your building project by collaborating with a trustworthy structural steel building supplier.

With over 20 years of experience, we have developed the flexibility to build a range of categories: modular steel structures, rigid portal frames, space frame structures, space truss structures, steel bridges, and more. Our prefab steel structure is made with qualified, cost-effective materials and serviced to our clients with professionalism in mind. Just let us know! We are ready to listen and adjust to your needs.

We understand that every building project needs different steel structure solutions. That’s why we offer various services based on what your project needs. Our engineering service collaborates with contractors to evaluate what kind of steel structure the project needs. Our fabrication service supplies steel construction materials sourced from qualified raw materials. We also offer steel structure installation and management services to ensure all the parts of the steel in the building phase are professionally embedded with follow-up maintenance to preserve the building’s performance in the long run.

We update the company news and industry blogs, steel structure china with expert tips and guides related to modular steel structures that you may find useful.

As sustainability becomes a core priority across global industries, factory construction is increasingly evaluated not only by cost and performance, but also by environmental impact.

Steel factory buildings play a critical role in modern industrial production, supporting heavy equipment, overhead cranes, high traffic loads, and flexible manufacturing layouts. Unlike conventional

Industrial warehousing has evolved far beyond simple storage buildings. Today’s facilities must support high-density storage, efficient material flow, automation systems, and future expansion—all while keeping

We produce many types of steel structures, which including standardized rigid portal frame steel structure, space frame steel structure, space truss steel structure, special-shaped space truss steel structure, special-shaped space tube truss steel structure, steel structure concrete high-rise, steel structure corridor, structural steel bridge, steel structure industrial working platform, steel structure infrastructure (steel structure towers, steel structure lightning protection towers, steel structure signal towers, steel structure power transmission systems), single board maintenance (color profiled board series), single board maintenance (floor board series), single board maintenance (wall sandwich panel series), and steel structure engineering supporting products (c-type, z-type, angle steel, channel steel, square tube, etc.).

Yes, our steel structure project clients are located on five continents and cover more than 20 countries and regions, including Angola, Australia, Cambodia, Congo, Cook Islands, Ethiopia, Indonesia, Lesotho, Libya, Malaysia, Mozambique, Pakistan, Panama, Papua New Guinea, Philippines, Serbia, South Africa, Thailand, Turkey and Vietnam.

XTD Steel Structure has three steel structure processing bases located in Suzhou, Jiangsu Province, Yichun, Jiangxi Province, and Guangzhou, Guangdong Province, with a total annual production capacity of up to 100,000 tons. The Suzhou Steel Structure Assembly and Processing Base covers an area of 87,000 square meters, with a professional team of more than 200 skilled steel structure technicians and 6 fully integrated steel structure production lines, with a monthly production capacity of more than 4,300 tons. The Yichun Steel Structure Processing Base covers an area of 82,000 square meters, with nearly 100 professional technicians, and has set up 3 production lines for heavy steel structure components, 2 production lines for light steel structure components, 1 production line for steel structure net frame, 1 production line for steel structure pipe support, and the max. lifting capacity of truss trucks is up to 32 tons, with a monthly production capacity of up to 4,000 tons. The Guangzhou Steel Structure Processing Base covers an area of nearly 10,000 square meters, with 3 complete steel structure processing lines and a monthly capacity of 1,000 tons.

According to customers’ requirements, we can provide steel structure design solutions in line with Chinese(GB), American(ASIC) and European standards(CE), and the materials used also fully meet the standards and specifications of China, the U.S., Europe, Japan, and Germany.

We conform to ISO (International Organization for Standardization), AWS D1.1 (American Welding Society), and CE (Conformité Européene) standard certifications for the steel structure industry.

Contact us today for a free consultation and see why XTD Steel Structure is China’s leader in prefab steel systems. Ensure a strong and impactful building project by selecting XTD Steel Structure as your steel modular construction supplier and let’s build something strong—together.

Knowing where you plan on building is essential to providing an accurate building estimate.