In the fast-evolving world of architecture and engineering, the spatial structure has emerged as one of the most transformative construction systems of the 21st century. This innovative three-dimensional structural form combines strength, efficiency, and design flexibility, enabling architects and engineers to create large-span spaces without interior supports. From airports and stadiums to industrial warehouses and exhibition halls, spatial structures are shaping how we build modern spaces that balance aesthetics with functionality.

Understanding Spatial Structure Systems

Definition and Core Principles of Spatial Structure

A spatial structure is a sophisticated three-dimensional framework composed of interconnected elements such as beams, rods, or cables, meticulously arranged to form a stable, self-supporting load-bearing system. Unlike conventional planar frames that distribute loads primarily along one plane, a spatial structure transfers forces through multiple directions simultaneously, enabling superior rigidity, structural stability, and weight efficiency. This multidirectional force distribution allows engineers to design large-span spaces with minimal material use while maintaining exceptional strength and resilience.

At the heart of every spatial structure lies a series of fundamental principles that define its performance and versatility. The first is three-dimensional load transfer, where forces are dispersed evenly through a web of nodes and members rather than relying on linear support systems. This design minimizes localized stress and enhances the overall durability of the structure.

Second, geometric stability—achieved through triangulated configurations—ensures that the framework resists deformation even under dynamic or asymmetrical loading conditions such as wind, snow, or seismic activity. Another defining characteristic is material efficiency: by optimizing geometry and force paths, engineers can achieve high strength with a fraction of the steel required in traditional designs. Finally, aesthetic adaptability stands as one of the most appealing features of spatial structures. Their flexible geometry supports the creation of elegant architectural forms, including domes, spheres, vaulted roofs, and free-form shells that define modern architectural expression.

The combination of these principles enables spatial structures to meet the twin demands of engineering performance and architectural creativity. Their ability to cover vast spaces without internal columns makes them the system of choice for sports arenas, airport terminals, exhibition centers, and cultural landmarks around the world.

Historical Development and Technological Evolution

The concept of the spatial structure has evolved significantly since its introduction in the early 20th century. Its historical roots trace back to visionary inventor and architect Buckminster Fuller, who pioneered the geodesic dome—a lightweight, spherical structure composed of triangular elements that evenly distribute stress across its surface. Fuller’s innovation demonstrated that geometry could achieve both efficiency and beauty, laying the foundation for what would become a major engineering revolution.

In the decades that followed, the evolution of computational analysis and material science transformed spatial structure engineering into a sophisticated discipline. The introduction of finite element analysis (FEA) allowed engineers to simulate complex load interactions within 3D frameworks, leading to more accurate and efficient designs. Computer-aided design (CAD) further expanded creative possibilities by enabling parametric modeling of intricate geometric forms, from curved surfaces to asymmetrical grids. This fusion of mathematics, computing, and design redefined what could be achieved with steel and lightweight alloys.

Modern spatial structure systems now integrate advanced digital technologies and automated fabrication techniques to achieve unprecedented precision and efficiency. Digital twin modeling, for instance, creates a virtual replica of a physical structure, allowing real-time monitoring and simulation of performance under varying conditions. This technology enables predictive maintenance, ensuring long-term reliability and safety. Additionally, the use of high-performance steel grades such as Q355B and S355JR provides exceptional strength-to-weight ratios while maintaining ductility and weldability, making them ideal for large-span and high-load applications.

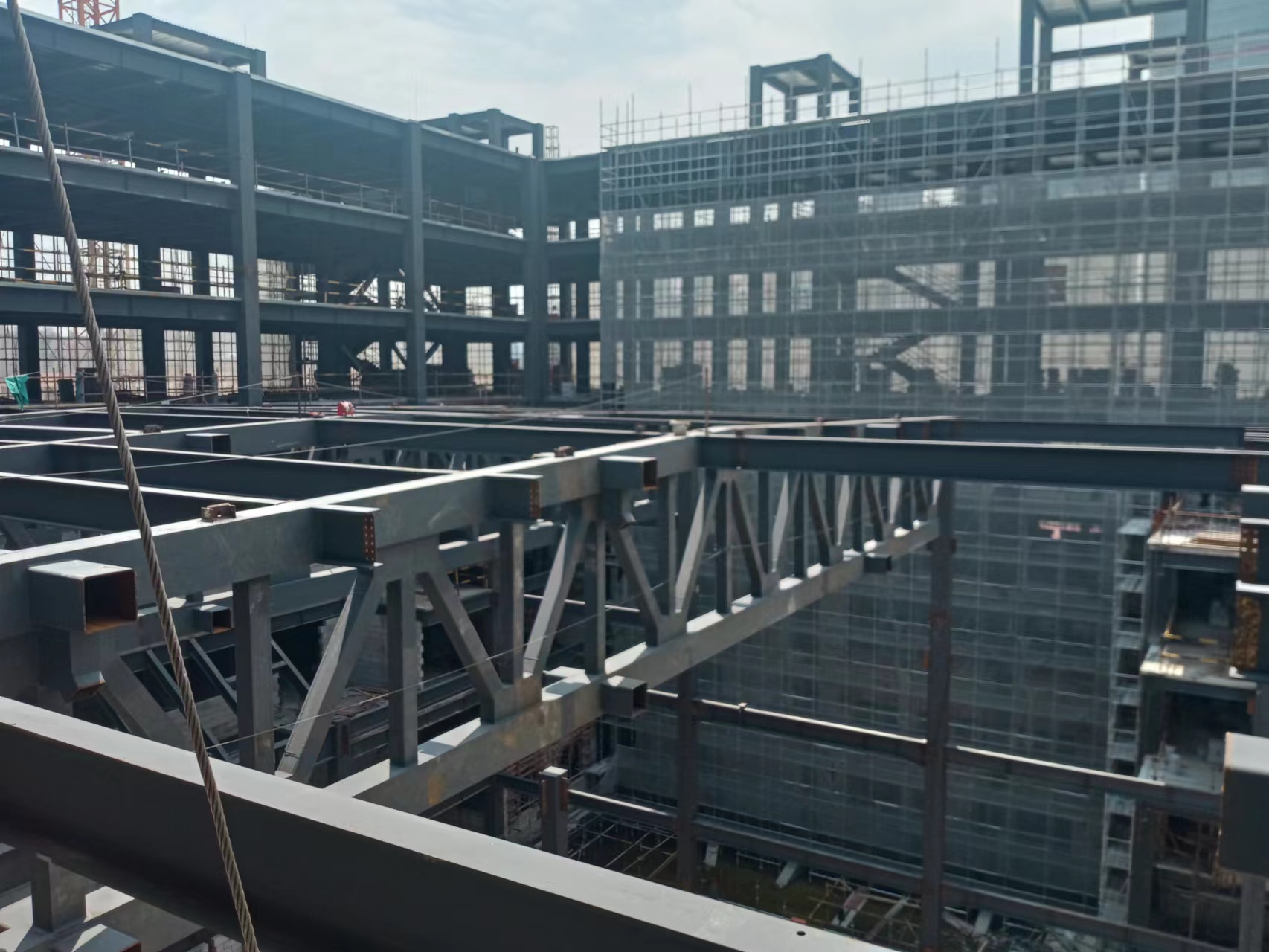

Automation has also revolutionized the way spatial structures are built. Modular fabrication techniques allow components to be prefabricated in controlled factory environments, ensuring high accuracy and minimal error during assembly. Onsite labor is significantly reduced, and installation times are shortened as preassembled modules are joined using ball-joint connections or bolt-and-node systems. This industrialized approach not only improves construction speed and cost efficiency but also ensures consistent quality across projects.

Today’s spatial structures stand at the intersection of art, science, and technology. They represent the culmination of decades of innovation—from the early experimental domes of Buckminster Fuller to the>geometric intelligence, sustainable materials, and computational design, spatial structures continue to push the boundaries of what’s possible in modern construction, creating buildings that are lighter, stronger, and more expressive than ever before.

Key Characteristics and Advantages of Spatial Structure

The spatial structure stands out as one of the most innovative and efficient engineering systems in modern construction. Its unique combination of strength, lightness, and flexibility provides architects and engineers with the ability to create large, open, and visually impressive spaces that traditional structural systems cannot easily achieve. From monumental stadiums and exhibition centers to industrial plants and airports, the spatial structure delivers exceptional performance through its intelligent use of geometry and materials. The following characteristics highlight why this system has become indispensable in contemporary architecture and large-scale engineering.

Lightweight Yet High Load-Bearing Capacity

One of the defining advantages of the spatial structure is its remarkable ability to achieve lightweight construction without compromising load-bearing performance. The system relies on triangulated geometry, where interconnected members form stable, three-dimensional frameworks that efficiently distribute loads throughout the structure. This geometric configuration provides maximum stiffness while minimizing material use, resulting in exceptional strength-to-weight ratios.

Unlike traditional beam or truss systems that transfer loads along single planes, a spatial structure spreads the forces in multiple directions, allowing it to support large spans exceeding 100 meters or more without the need for intermediate columns. This makes it particularly suitable for applications that demand wide, unobstructed interior spaces such as sports stadiums, aircraft hangars, and industrial warehouses.

Additionally, the reduced self-weight of the structure minimizes stress on the foundation, enabling lighter substructures and lower foundation costs. The combination of efficiency and lightness not only enhances safety and stability but also contributes to the overall economic performance of a project.

Design Flexibility and Aesthetic Appeal

Beyond structural performance, the spatial structure is celebrated for its design versatility and aesthetic possibilities. The three-dimensional nature of the system allows architects to explore curved, domed, and free-form geometries that embody creativity and modern expression. Whether creating a soaring exhibition hall roof or a complex glass canopy, the system provides both visual drama and technical precision.

This flexibility extends to material integration. Spatial structures easily accommodate other architectural materials such as glass, aluminum, ETFE membranes, or polycarbonate panels, resulting in transparent or semi-transparent enclosures that maximize natural light while maintaining structural integrity. The harmonious blending of form and function allows designers to craft spaces that are not only structurally efficient but also visually inspiring.

For public buildings, cultural landmarks, and transport hubs, the use of a spatial structure enhances the sense of openness and grandeur. The visible steel lattice often becomes an architectural feature in itself, symbolizing innovation and modernity. In this way, the system bridges the gap between engineering efficiency and artistic design, embodying the essence of “structure as architecture.”

Construction Efficiency and Material Optimization

The adoption of modular and prefabricated construction methods is another major advantage of the spatial structure. Most of its components—such as nodes, tubes, and connecting joints—are manufactured off-site under strict quality control conditions. These standardized steel elements are then transported to the construction site and assembled rapidly using bolted or welded connections.

This industrialized approach ensures precision, speed, and cost efficiency, making spatial structures highly suitable for large-scale or time-sensitive projects. Prefabrication reduces on-site labor, shortens project timelines, and minimizes the environmental impact associated with traditional construction. Moreover, the modular nature of the system allows for high repeatability, enabling the same design principles to be replicated across multiple projects or adapted for different functions.

Material optimization plays a crucial role in the sustainability and economy of spatial structures. By using steel members of optimized cross-section sizes and strategically arranging them into triangulated grids, engineers achieve maximum strength with minimum material consumption. This not only conserves resources but also simplifies logistics and assembly operations, leading to a cleaner and safer construction process.

Durability and Sustainability Benefits

A well-designed spatial structure is built to last. The use of high-strength, corrosion-resistant steel—often protected through galvanization or specialized coatings—ensures excellent durability even in harsh environmental conditions. This makes spatial structures ideal for both indoor and outdoor applications, including coastal or humid regions where corrosion control is critical.

From a sustainability perspective, spatial structures align perfectly with the principles of green construction. Steel, being 100% recyclable, contributes to circular economy goals and reduces environmental waste. Many components can be reused or repurposed after a building’s life cycle, providing long-term ecological benefits. Furthermore, the inherent efficiency of the system—through material savings, lightweight design, and energy-efficient fabrication—reduces carbon emissions from manufacturing to assembly.

The low maintenance requirements of spatial structures further enhance their sustainability credentials. Unlike reinforced concrete, which may suffer from cracking and reinforcement corrosion, properly maintained steel spatial structures can achieve lifespans exceeding 50 years with minimal upkeep. Many modern projects also integrate protective coatings, drainage systems, and inspection-friendly joints to further extend service life.

For projects pursuing environmental certifications such as LEED or BREEAM, spatial structures contribute positively to energy performance, resource optimization, and waste reduction credits. They represent a future-oriented construction philosophy—one that merges longevity, adaptability, and environmental stewardship into a single structural solution.

Major Applications of Spatial Structure in Modern Construction

The versatility of the spatial structure makes it one of the most widely applied systems in contemporary architecture and engineering. Its superior strength-to-weight ratio, ability to cover large spans, and architectural freedom allow it to serve diverse functions—from massive sports arenas to sustainable agricultural greenhouses.

By efficiently combining geometry, materials, and modular design, spatial structures provide flexible and visually striking solutions that meet both functional and aesthetic demands in modern construction.

Sports Stadiums and Arenas

Sports facilities represent one of the most prominent applications of spatial structure engineering. Modern stadiums depend on these systems to achieve vast, column-free interiors that enhance spectator experience and accommodate complex mechanical systems.

Key Examples:

- Beijing National Stadium (Bird’s Nest) – A hallmark of architectural innovation, its interlaced steel lattice structure exemplifies the power of double-layer spatial systems.

- Wembley Stadium Roof System, UK – Incorporates a retractable spatial truss design allowing clear views from every seat.

- Olympic Arenas Worldwide – Use reticulated shells and space frames for lightweight roofing and efficient acoustic control.

Advantages of spatial structure in sports facilities:

- Large-span coverage without internal supports.

- Enhanced visibility and ventilation.

- Integration with acoustic and lighting systems.

- Distinctive, iconic architectural form for branding and identity.

Technical Insight:

Typical stadium roof spans range between 120–300 meters, utilizing steel tube ball-joint connections for modular fabrication and rapid assembly.

Exhibition Centers and Convention Halls

Exhibition centers demand flexibility, open interiors, and architectural appeal—all of which align perfectly with the characteristics of the spatial structure system.

Key Features:

- Column-free halls accommodating dynamic event layouts.

- Modular spans adaptable to different exhibition scales.

- Integration of glass or polycarbonate panels for natural daylighting.

- Lightweight construction, enabling efficient load distribution for suspended displays or lighting rigs.

Advantages:

- Easy reconfiguration for different event types.

- Reduced construction time due to prefabricated modules.

- Compatibility with large HVAC and lighting systems.

- Elegant, modern visual design that enhances visitor experience.

Example Projects:

- Shanghai New International Expo Center, China.

- Dubai World Trade Centre, UAE.

- Guangzhou Canton Fair Complex, featuring 100m-span space grid roofing.

Engineering Note:

Exhibition halls often adopt double-layer grid structures for long spans, with the upper layer resisting compression and the lower layer handling tension, ensuring optimal load distribution.

Airport Terminals and Transportation Hubs

Transportation infrastructure showcases some of the most sophisticated spatial structure applications, combining large span efficiency with aesthetic precision.

Spatial structure systems in airports and transit stations provide:

- Vast concourse coverage with minimal internal columns.

- Architectural continuity between terminal spaces and roof canopies.

- Integrated mechanical, electrical, and plumbing (MEP) systems concealed within structural elements.

Examples:

- Beijing Capital International Airport Terminal 3 – Uses space trusses to achieve a light, aerodynamic form.

- Hamad International Airport, Qatar – Employs hybrid steel–aluminum structures for maximum efficiency.

- Hong Kong International Airport Roof System – Showcases modular steel grids allowing natural illumination.

Benefits:

- Reduced weight and faster assembly time.

- Improved energy efficiency through daylight optimization.

- High seismic resistance and flexibility under temperature variations.

Table: Spatial Structure in Transport Facilities

| Facility Type | Span Range (m) | System Type | Key Benefit |

|---|---|---|---|

| Airport Terminal Roof | 80–150 | Double-Layer Grid | Large-span coverage |

| Metro Station | 30–60 | Space Frame | Quick installation |

| Railway Hub | 60–120 | Reticulated Shell | Natural light & energy efficiency |

Industrial Plants and Warehouses

In the industrial sector, the spatial structure offers a balance between practicality, cost efficiency, and engineering strength.

Applications include:

- Manufacturing plants requiring clear spans for production lines.

- Warehouses and logistics centers needing large storage capacity.

- Power stations and processing facilities demanding robust overhead support for cranes and utilities.

Advantages:

- Long-span design (40–100m) for unobstructed workflow.

- Fast assembly using prefabricated modular units.

- Reduced maintenance and high corrosion resistance.

- Adaptability for future expansion or layout changes.

Example:

The Hebei Jin’ou Warehouse Structure, engineered by XTD Steel Structure, covers 13,000㎡ using a standardized portal rigid frame combined with a space truss roof. The result is a cost-effective, high-performance building optimized for industrial efficiency.

Public and Cultural Buildings

Beyond functional needs, spatial structure systems are integral to public architecture, where visual impact and open interior space are key.

Common applications:

- Museums, galleries, and theaters demanding wide, uninterrupted display areas.

- Libraries and civic centers featuring transparent, open-plan designs.

- Religious and memorial structures emphasizing lightness and symbolism.

Advantages:

- Supports large roof spans while maintaining slender aesthetics.

- Allows creative architectural expressions such as domes or vaulted ceilings.

- Integrates modern materials like glass, aluminum, and tensile membranes.

Example:

The Suzhou Cultural Exhibition Hall features a steel reticulated shell spatial structure that merges art with engineering—balancing transparency, strength, and form.

Result:

These cultural structures demonstrate how spatial structures bridge art, functionality, and sustainability in contemporary design.

Greenhouses and Lightweight Roof Systems

Agricultural and environmental construction also benefit from the spatial structure’s lightweight yet durable design.

Applications:

- Botanical gardens with transparent domes.

- Eco-greenhouses requiring controlled thermal environments.

- Sustainable agricultural facilities optimized for sunlight and ventilation.

Advantages:

- High transparency with glass or ETFE membrane roofing.

- Minimal shadow areas maximizing photosynthetic efficiency.

- Resistance to wind and snow loads with lightweight members.

- Easy integration of ventilation and shading systems.

Example:

Modern ecological greenhouses in China and the Netherlands use single-layer spatial structures combining aluminum frames and polycarbonate panels, achieving both environmental control and reduced material usage.

Summary Table: Applications of Spatial Structure

| Sector | Common Structure Type | Average Span (m) | Key Benefits |

|---|---|---|---|

| Sports Stadiums | Double-Layer Grid / Reticulated Shell | 100–300 | Column-free views, iconic aesthetics |

| Exhibition Halls | Space Frame / Hybrid Grid | 60–120 | Flexible layout, natural lighting |

| Airport Terminals | Space Truss / Grid Shell | 80–150 | Efficient span, seamless integration |

| Industrial Warehouses | Portal Frame + Space Roof | 40–100 | Strength, cost efficiency |

| Public Buildings | Reticulated Shell / Space Dome | 50–120 | Modern aesthetics, openness |

| Greenhouses | Single-Layer Space Frame | 20–60 | Lightweight, sustainable design |

Structural Types of Spatial Structure Systems

| Type | Description | Applications | Key Advantages |

|---|---|---|---|

| Double-Layer Grid | Two parallel layers of interconnected bars | Stadium roofs, terminals | High rigidity and load resistance |

| Single-Layer Reticulated Shell | Curved shell using single-layer members | Domes, atriums | Lightweight, visually elegant |

| Space Truss | Triangular frame with diagonal braces | Industrial roofs | Simple, cost-effective |

| Cable-Tensioned System | Uses cables and rods for tension support | Exhibition halls, tents | Ultra-lightweight, aesthetic |

| Hybrid Composite Frame | Combines steel, glass, and membrane | Modern pavilions | Energy-efficient and flexible design |

Each spatial structure system is chosen based on span, function, and desired aesthetics.

Design and Engineering Considerations

Designing an efficient spatial structure requires precise engineering, simulation, and fabrication processes.

Load Analysis and Finite Element Modeling

- Evaluate wind, snow, and seismic loads using FEA software.

- Assess nodal stresses and member deflection.

- Optimize geometry for maximum stiffness with minimal material.

Connection Systems and Material Selection

Connection design defines the safety and longevity of spatial structures:

- Bolted ball joints for modular assembly.

- Welded nodes for permanent systems.

- Use of high-strength steel (Q355B, S355JR, A572) for superior performance.

Prefabrication, Assembly, and Quality Control

- Prefabricate modules in controlled factory environments.

- Assemble using cranes and precision jigs onsite.

- Quality control through 3D laser scanning ensures accuracy.

Benefits of prefabrication include:

- Faster installation

- Lower labor cost

- Minimal onsite welding

Innovations and Future Trends in Spatial Structure Engineering

The evolution of the spatial structure has entered a new era defined by digital intelligence, hybrid materials, and sustainability. As construction demands become increasingly complex, engineers and architects are adopting advanced technologies and materials to make spatial structures more efficient, adaptive, and environmentally responsible. The integration of digital twin systems, smart monitoring, and lightweight composites is transforming how spatial structures are designed, built, and maintained.

Integration with Digital Twin and Smart Monitoring

In the digital age, smart monitoring systems have become a cornerstone of modern spatial structure engineering. By embedding intelligent sensors within the steel framework, engineers can now track the real-time health and performance of large-scale spatial structures with remarkable accuracy.

1. Real-time structural health monitoring

Sensors installed on joints, nodes, and critical members continuously measure deflection, vibration, stress, and temperature variations. This constant flow of data helps detect early signs of fatigue, deformation, or environmental stress, ensuring structural reliability throughout its service life.

2. Integration with Building Information Modeling (BIM)

The collected data is seamlessly integrated into BIM platforms, creating a dynamic digital model—often referred to as a Digital Twin—that mirrors the physical behavior of the spatial structure. This virtual replica enables:

- Predictive maintenance, preventing costly repairs or downtime.

- Performance visualization, helping clients and engineers monitor conditions remotely.

3. AI-driven predictive analytics

With the rise of artificial intelligence (AI) and machine learning, predictive algorithms analyze historical performance data to anticipate potential weak points before failure occurs. AI-assisted systems can suggest reinforcement strategies, load adjustments, or temperature-based stress compensations to enhance safety.

Example:

In large-span airport terminals or stadiums, AI-integrated monitoring helps predict member fatigue from dynamic wind loads, thermal expansion, and snow accumulation—issues that traditional inspection methods often miss.

Outcome:

By combining Digital Twin technology, IoT sensors, and AI analytics, modern spatial structure systems are transitioning from static designs to intelligent, self-diagnosing frameworks that continuously evolve with environmental and operational conditions.

Hybrid Materials and Lightweight Composites

Material science innovation is redefining how spatial structures are fabricated and optimized. The new generation of hybrid and composite materials merges strength with sustainability, allowing for lighter yet stronger frameworks.

1. Steel and carbon fiber synergy

The integration of carbon-fiber-reinforced polymers (CFRP) with structural steel delivers a unique combination of high tensile strength and corrosion resistance. These hybrid systems can reduce the total structural weight by up to 30%, improving transportation efficiency and minimizing foundation loads.

2. Aluminum and glass composites

Lightweight aluminum alloys are increasingly used in space truss systems and reticulated shells, especially for portable pavilions, exhibition halls, and transportable structures. When combined with laminated glass or ETFE membranes, they create transparent and energy-efficient enclosures.

3. Advantages of hybridization

- Improved load-to-weight ratio and seismic performance.

- Reduced maintenance costs due to corrosion-resistant properties.

- Enhanced adaptability for modular and relocatable designs.

Example Applications:

- Temporary expo domes constructed with steel–CFRP frames.

- Aerospace-inspired lightweight roofs for transportation hubs.

- Eco-resorts and glamping structures requiring fast assembly and mobility.

Sustainable Architecture and Adaptive Reuse

Sustainability is no longer an optional element in spatial structure design—it’s a global mandate. Engineers are developing adaptable frameworks that minimize environmental impact while maximizing lifecycle efficiency.

1. Modular and reusable design philosophy

Modern spatial structure frameworks are increasingly designed for disassembly and relocation, enabling reuse across multiple projects. Bolted ball joints and prefabricated modular grids make it possible to dismantle and reassemble entire roofs or enclosures with minimal waste.

2. Reduction of embodied carbon

By using recyclable high-strength steel and lightweight materials, spatial structures drastically lower embodied carbon compared to reinforced concrete alternatives. Many projects now implement Life Cycle Assessment (LCA) tools to measure total emissions and energy consumption.

3. Global green certification standards

To align with international sustainability benchmarks, leading engineering firms ensure their spatial structure systems comply with:

- LEED (Leadership in Energy and Environmental Design)

- BREEAM (Building Research Establishment Environmental Assessment Method)

- China’s Three-Star Green Building Rating System

4. Future adaptive architecture

The concept of “adaptive reuse” extends beyond recycling materials—it focuses on designing buildings that can evolve over time. A spatial structure can be transformed from a sports arena into an exhibition hall, or from a warehouse into a community center, simply by modifying its cladding or layout without altering the main frame.

The Road Ahead

The future of spatial structure engineering lies in intelligent integration, sustainable design, and material innovation. As the construction industry embraces digital ecosystems and green technologies, the next generation of spatial structures will not only support massive spans but also interact, adapt, and sustain themselves intelligently within their environments. From AI-monitored stadiums to modular green terminals, the spatial structure will remain a central element in redefining how we envision architectural freedom and structural performance in the decades ahead.

Case Studies of Modern Spatial Structure Projects

Beijing National Stadium (Bird’s Nest)

A global icon of spatial structure engineering, the Bird’s Nest features an intricate lattice of interwoven steel beams.

- Span: 330 meters

- Steel Usage: 42,000 tons

- Feature: Double-layered truss system providing aesthetic and structural depth.

XTD Steel Structure Landmark Projects

XTD Steel Structure has delivered numerous large-span spatial structure projects worldwide, showcasing precision engineering and efficient execution.

| Project Name | Location | Steel Usage | Completion Time | Structure Type |

|---|---|---|---|---|

| Indonesia Sinar Mas Warehouse | Indonesia | 1,250 tons | 2024 | Space Frame |

| Angola Bridge Roof System | Angola | 107 tons | 2023 | Space Truss |

| Hebei Jin’ou Industrial Warehouse | China | 620 tons | 2022 | Double-Layer Grid |

| Shanghai Exhibition Center | China | 800 tons | 2021 | Reticulated Shell |

These examples demonstrate how spatial structures provide both aesthetic and functional excellence, enhancing global industrial and commercial infrastructure.

Conclusion

The rise of the spatial structure marks a defining evolution in modern construction. Its strength, flexibility, and sustainability make it the preferred solution for architects and engineers seeking efficiency without compromising creativity. By combining advanced fabrication, computational design, and eco-friendly materials, spatial structures enable the creation of landmark buildings that inspire and perform. As a leading engineering and fabrication enterprise, XTD Steel Structure continues to push the boundaries of spatial structure design, offering customized, high-performance steel solutions for global projects.