Single Board Maintenance (Wall Sandwich Panel Series) Advantages

|

|

|

|

|

|

When discussing modern construction practices, the use of single board maintenance systems, particularly the wall sandwich panel series, has emerged as a major innovation in both efficiency and safety. These systems are designed not only to streamline the construction process but also to enhance the durability and performance of the finished structure. Their widespread adoption across residential, commercial, and industrial buildings is a testament to their long-term value and practicality.

Replacement of Traditional Formwork

One of the most significant advantages of wall sandwich panels lies in their ability to completely replace traditional formwork. In conventional construction, large amounts of time, labor, and resources are spent on erecting, aligning, and later dismantling temporary formwork boards for concrete walls. This process is labor-intensive, time-consuming, and often prone to human error. By using sandwich panels, builders can eliminate these steps almost entirely.

Instead of dealing with complex assemblies, the panels are installed directly as both formwork and finished wall components. This integration reduces the need for extra materials and lowers waste, while also cutting down on construction costs. For projects where time is critical—such as large-scale industrial plants, warehouses, or commercial facilities—the time saved in reducing board erection and disassembly is invaluable. It allows for faster completion of projects, which in turn improves profitability and accelerates occupancy or operational readiness.

Improved Efficiency in Floor and Wall Construction

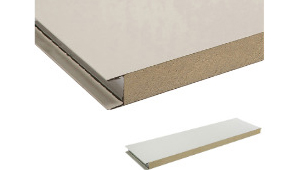

Sandwich panels are also praised for greatly improving the efficiency of floor and wall construction. With pre-fabricated dimensions and lightweight properties, panels can be installed quickly with minimal labor. Unlike traditional building methods, where each stage of construction depends heavily on curing times or multiple trades working sequentially, sandwich panels simplify the process into fewer stages.

The panels are typically manufactured under controlled factory conditions, which ensures consistent quality and accuracy. Once delivered to the site, they are assembled with precision and speed. This reduces dependence on on-site weather conditions, as adverse factors like heavy rain or high humidity—common challenges in many regions—do not affect the performance or assembly process as much as they would traditional construction materials.

Fire Protection and Safety Performance

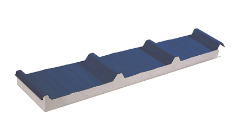

Another essential advantage of wall sandwich panels is their superior fire protection performance. The surface material and insulation material used in sandwich panels are generally non-combustible or designed to be difficult to ignite. This directly supports compliance with fire protection regulations, which are becoming increasingly stringent across the globe.

In addition to regulatory compliance, the use of fire-resistant materials contributes significantly to the safety of occupants and the overall resilience of the building. In the event of a fire, sandwich panels can prevent the rapid spread of flames, giving occupants more time to evacuate and reducing potential property damage. For industrial facilities where flammable materials may be stored or handled, this aspect of safety cannot be overstated. The assurance of enhanced fire performance also reduces insurance risks and costs for building owners.

Structural Integrity and Durability

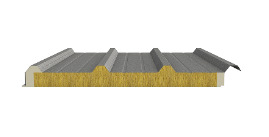

Wall sandwich panels are engineered to provide long-term durability. Their composite structure combines outer steel sheets with insulating core materials such as polyurethane (PU), polyisocyanurate (PIR), or mineral wool. This combination offers both strength and thermal performance, ensuring that the panels do not deform or weaken under environmental stress.

Furthermore, sandwich panels protect the structural integrity of the main building. Acting as both cladding and insulation, they serve as a shield against weather conditions such as rain, wind, and temperature fluctuations. Over time, this protection reduces maintenance costs and extends the building’s service life. Unlike traditional walls that may require frequent plastering, painting, or waterproofing, sandwich panels require little to no maintenance once installed.

Sustainability and Energy Efficiency

In today’s construction industry, energy efficiency and sustainability are major considerations. Sandwich panels offer excellent thermal insulation properties, which reduce the need for artificial heating and cooling. By minimizing thermal bridging and maintaining stable indoor temperatures, they help to lower energy consumption and carbon emissions.

Their lightweight design also reduces the overall load on the structural framework, which can cut down the amount of steel or concrete needed in the supporting structure. This results in further resource savings and reduces the environmental impact of the building. In addition, many sandwich panels are recyclable at the end of their life cycle, aligning with modern sustainable construction practices.

Application Versatility

Finally, wall sandwich panels are highly versatile in their applications. They can be used in warehouses, factories, office complexes, shopping centers, and even in residential housing. Their aesthetic flexibility, with a wide range of colors and surface finishes, makes them suitable for both functional and decorative purposes. Whether used for external cladding or internal partitioning, they provide a clean, modern appearance that enhances the overall architectural value of a building.

The Single Board Maintenance Wall Sandwich Panel Series represents a forward-thinking solution in modern construction. By eliminating the need for formwork, reducing labor, and enhancing fire safety, these panels offer undeniable advantages.

Their structural durability, energy efficiency, and wide application potential make them not only a cost-effective choice but also a sustainable one. As the construction industry continues to evolve, sandwich panels are set to play an increasingly vital role in ensuring that projects are completed faster, safer, and with higher performance standards.

Application scenarios: construction projects, municipal projects, industrial plants, public facilities

|

|

|