Steel Structure Factory project in Banten, Indonesia, delivering a high-efficiency industrial workshop engineered for strength, speed, and long-term performance. Completed in August 2025, the facility integrates standardized modules for rapid assembly, optimized spans, and cost-effective operation.

Technical Specifications

| Item | Specification |

|---|---|

| Structural System | |

| Steel Grades | Typical options: Q355B / S355JR / ASTM A572 / SM490A (to confirm) |

| Roof System | Insulated sandwich panels or single-skin + insulation (project-based) |

| Wall System | Insulated panels / metal cladding with daylighting strips |

| Corrosion Protection | Hot-dip galvanizing or primer + topcoat (environment-class based) |

| Design Standards | GB / EN 1993 / AISC (as applicable) |

| Seismic/Wind | Designed to local code loads (site data required) |

Engineering & Design

Structural Layout

Efficient bay spacing is planned around production equipment, forklifts, and logistics aisles to minimize cross-traffic and idle time. In a steel structure factory, clear spans and calibrated gridlines keep columns out of process bottlenecks and allow flexible retooling as product lines evolve.

Where lifting is required, integrated crane beams and runway girders are coordinated with service corridors and maintenance catwalks. The steel structure factory design also matches foundations to geotechnical findings, with load paths verified from roof purlins to soil-bearing strata. Expansion joints, mezzanines, and knock-out panels are reserved for future capacity increases.

Envelope & Performance

The building envelope is engineered to support productivity and protect assets. For the steel structure factory envelope, we specify thermal insulation to stabilize internal temperatures and reduce energy spend, while controlling condensation around sensitive machinery. Ventilation rates are sized for heat loads and process emissions; smoke extraction is integrated with fire strategy to maintain safe egress conditions. Daylighting via skylights or translucent panels improves visual comfort, reduces lighting demand, and supports safety without glare on workstations.

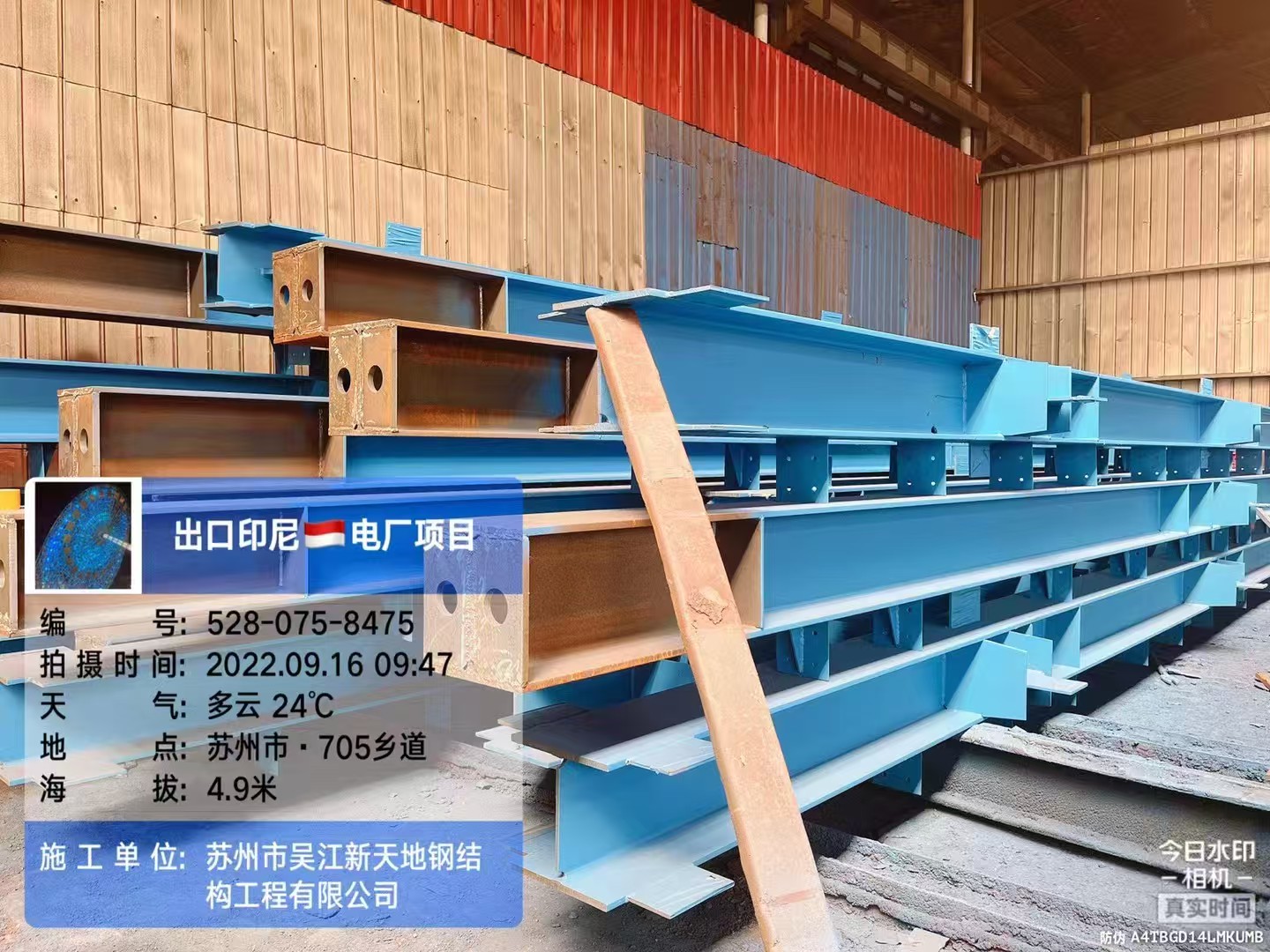

Fabrication & Construction

Digital coordination drives predictable delivery. Shop drawings and federated models lock in member sizes, connection details, and penetrations before steel is cut. Within the steel structure factory workflow, precision fabrication, trial fits, and QC checkpoints ensure dimensional control prior to shipment. On site, sequenced deliveries align with erection order, enabling rapid cranage, stable temporary bracing, and safe access for follow-on trades. Final alignment, calibrated bolting, envelope installation, and commissioning are executed under a single, traceable plan from break ground to handover.

Quality, Safety & Compliance

Every steel structure factory project adheres to qualified WPS/PQR procedures, with welding inspections (VT/MT/UT where required) logged against heat numbers and member IDs. Bolt tension is verified with calibrated tools, and dimensional inspections confirm plumb, line, and level before closing up cladding. Coating thickness and adhesion tests validate corrosion protection systems, particularly in humid or industrial atmospheres. Handover includes as-builts, test certificates, and a practical O&M manual so maintenance teams can sustain performance with confidence.

Sustainability

A modern steel structure factory supports circularity from the outset. High recycled-content steel reduces embodied carbon while maintaining mechanical performance; modular detailing enables disassembly, reuse, or component recovery at end of life. Prefabrication cuts on-site waste, limits disturbance, and compresses schedules, reducing transport and temporary works. Optional rainwater harvesting provisions tie gutters and downpipes to storage for non-potable uses, while roof geometry and cable routing are made solar-ready to accelerate future PV adoption.

Why it works

- The structural grid is tuned to process flow, minimizing forklift conflicts and dead corners.

- Crane integration and service corridors allow overhead handling without compromising safety zones below.

- Foundation design follows the soil report, optimizing footing sizes and reinforcing where point loads are highest.

- A high-performance envelope stabilizes temperature and air quality while daylighting boosts safety and morale.

- Model-driven fabrication and sequenced delivery reduce errors, enabling faster, safer erection.

- Verified welding, bolting, and coatings protect uptime and extend service life.

- Circular design choices future-proof the asset and lower total cost of ownership.

This approach delivers a resilient, adaptable, and efficient production environment—exactly what owners expect from a next-generation steel structure factory.

Related Solutions

FAQ: Steel Structure Factory

-

What are the main benefits of a Steel Structure Factory?

- Rapid construction, large clear spans, durability, and lower lifecycle costs.

- Speed: High prefabrication ratio shortens on-site work.

- Clear spans: Column-free bays enable flexible production layouts and future retooling.

- Durability: Engineered steel grades with certified welding and coatings for long service life.

- Cost over life: Fewer foundations, lighter roof/wall systems, and easier maintenance reduce TCO.

- Sustainability: High recycled content steel, low waste, and easy disassembly/reuse.

-

How fast can a Steel Structure Factory be delivered?

- Lead time depends on design finalization, fabrication queue, and site readiness; prefabrication accelerates the schedule.

- Typical ranges: Concept & detailed design 2–6 weeks; fabrication 4–10 weeks; erection 3–8 weeks (scope/weather dependent).

- Critical path: Geotechnical report, permitting, anchor-bolt setting, and envelope procurement.

- Fast-track options: Standardized portal frames and pre-agreed bay modules.

-

Can the Steel Structure Factory integrate cranes and mezzanines?

- Yes—crane beams, walkways, and platforms can be designed into the primary frame.

- Overhead cranes: Single/double-girder with typical capacities (e.g., 5–50 t; higher on request) and defined service classes.

- Mezzanines: Customized live loads (e.g., 3.0–10.0 kN/m²+) for storage or light production.

- Vibration/deflection control: Serviceability limits set per code and equipment criteria.

- Future-proofing: Reserve columns/footings sized for potential crane upgrades.

-

What standards guide the Steel Structure Factory design?

- Design follows applicable international and local codes: GB/EN/AISC for structures, plus local Indonesian regulations and SNI for wind/seismic.

- Primary structure: EN 1993 (Eurocode 3) / AISC 360 / GB 50017 (as applicable).

- Connections & welding: EN 1993-1-8 / AISC/JGJ; WPS/PQR with qualified welders.

- Loads: Project-specific wind, seismic, live loads, and crane loads per local code and site data.

- Materials: S355JR / Q355B / ASTM A572 / SM490A or equivalent, with MTCs.

-

How is corrosion protection handled?

- Hot-dip galvanizing or multi-coat paint systems are specified to match the environment class.

- Coating strategy: Galvanized (inside/outdoor coastal) or primer + intermediate + polyurethane topcoat.

- Environment classes: Selection aligned to site conditions (e.g., C3–C5-M coastal/industrial exposure).

- Quality control: DFT checks, adhesion tests, holiday testing on critical items.

- Detailing: Seal welds/drip edges; add maintenance walkways for safe access.

-

What information is required for a precise quotation?

-

- Site location, wind/seismic parameters, and geotechnical report.

- Layout drawings: spans, bay spacing, eave/ridge heights, doors, docks.

- Functional loads: mezzanine loads, crane tonnage/coverage, suspended MEP.

- Envelope choices: roof/wall panel types, insulation R-values, skylights.

- Scope boundaries: foundations, floor slab, MEP, fireproofing, and accessories.

-

Which roof and wall systems are available?

-

- Roof: Insulated sandwich panels or single-skin + blanket/PIR insulation; skylights; ridge vents.

- Walls: Insulated panels or metal cladding with daylighting strips and integrated louvers.

- Rain management: Gutters/downpipes sized for Banten’s tropical rainfall; overflow provisions.

Get a Quote

Planning a Steel Structure Factory in Indonesia or abroad? Contact our engineering team for a fast proposal, drawings, and budgetary pricing.