The Cambodia steel structure factory detailed here showcases a high-efficiency

industrial facility built with a total rigid frame system. With

1,200 tons of steel and final handover in October 2024, the project

demonstrates how modern steel engineering, disciplined QA/QC, and streamlined

EPC coordination can deliver a reliable, scalable, and sustainable manufacturing asset.

Project Quick Facts

| Location | Cambodia |

| Steel Usage | 1,200 tons |

| Structure Type | Total Rigid Frame |

| Completion | October 2024 |

Project Overview & Objectives

This steel structure factory in Cambodia was conceived to support high-throughput,

flexible industrial production with minimal downtime for future layout changes.

The owner’s core objectives included: rapid delivery, robust structural safety, low

operating cost, and a building envelope optimized for thermal performance and durability.

To meet these goals, the team adopted a total rigid frame solution that

balances structural efficiency, predictable erection sequencing, and straightforward

maintenance for a tropical climate.

- Throughput & Flexibility: Column spacing and crane-ready bays planned for clear production flows and potential process reconfiguration.

- Construction Velocity: Factory prefabrication and kit-of-parts logistics enabled fast on-site assembly.

- Lifecycle Cost: Durable finishes, low-maintenance cladding, and standardized components control OPEX.

Structural Design Strategy

The total rigid frame system uses moment-resisting portals to provide lateral stability

without reliance on extensive bracing in primary bays, reducing obstructions in production areas.

This strategy ensures a clean internal volume for equipment, material handling, and crane paths while

maintaining high stiffness under wind and live loads typical of industrial operations.

Key Design Principles

- Load Path Clarity: Primary frames carry vertical gravity loads; end frames and bracing systems handle longitudinal forces.

- Service Integration: Allowances for MEP penetrations, overhead ducts, and cable trays planned at the model stage to minimize rework.

- Future Expansion: Structural allowances at gable ends and connection plates prepared for potential extension modules.

- Thermal Movement: Expansion joints and detailing at cladding interfaces to accommodate temperature differentials.

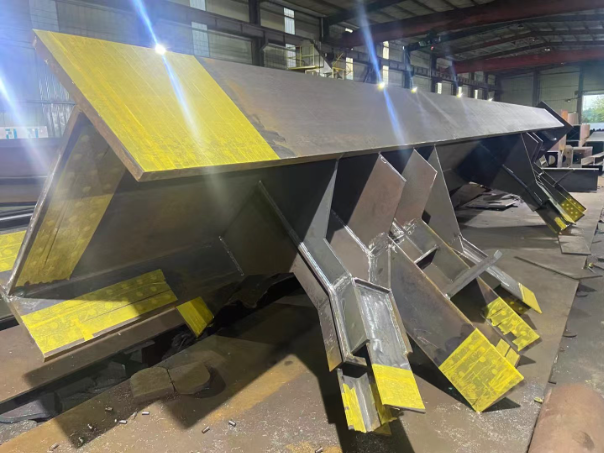

Framing & Connections

Primary frames comprise tapered or prismatic columns and rafters joined by full-strength

moment connections. Secondary members (purlins, girts) are arranged to stiffen cladding

and distribute roof and wall loads to the main frames. Connection design prioritizes repeatable

details and shop-friendly fabrication, improving dimensional control and erection speed.

Materials, Fabrication & Corrosion Protection

Material selection and fabrication quality directly influence the durability and schedule of a

steel structure factory. For this Cambodia project, structural steels with proven weldability

and consistency were specified, paired with modern workshop processes to reduce on-site adjustments.

Materials & Components

- Main Frames: Rolled or built-up H-sections for columns/rafters according to design loads and spans.

- Secondary Steel: Z/C purlins and girts for efficient roof/wall support.

- Bracing: Rod or angle bracing at roof and walls for diaphragm action and stability.

- Fasteners: High-strength bolts and self-drilling screws with compatible coatings.

- Cladding & Insulation: Metal sheets with insulation layers (e.g., rock wool or PIR) targeting thermal and acoustic performance.

Fabrication & Dimensional Control

- Shop drawings synchronized with BIM/3D coordination to protect clearances and penetrations.

- Weld procedure specifications (WPS/PQR) standardized; welder qualifications documented.

- Trial assemblies for critical nodes; marking and packing optimized for erection sequence.

Corrosion Protection

Given tropical humidity and potential coastal influences, the system uses a robust coating

stack (e.g., zinc-rich primer + epoxy intermediate + durable topcoat) or hot-dip galvanizing

for selected members. Cladding fasteners and accessories use compatible materials to prevent

galvanic corrosion, extending the factory’s service life.

Construction Methodology & Site Logistics

The build approach emphasized safe, repeatable processes to keep the October 2024 completion on track.

A crane-assisted sequence erected main portals first, followed by secondary framing and staged cladding installation.

Erection Sequence

- Foundations & Anchor Bolts: Survey control and anchor setting templates to maintain tight tolerances.

- Main Frames: Pair-by-pair lift and temporary bracing; plumb/line check after each bay.

- Secondary Steel: Purlins/girts installed to stabilize the frame and prepare for enclosure.

- Roof & Wall Cladding: Weather-tight shell established early to protect interior works.

- Doors, Skylights & Louvers: Integrated for daylighting and ventilation while controlling water ingress.

Site Logistics & HSE

- Just-in-time deliveries to minimize laydown congestion and double handling.

- Clearly delineated pedestrian/vehicle routes; craning zones fenced and supervised.

- Daily toolbox talks, lifting plans, and permit-to-work for hot works and heights.

QA/QC, Safety & Compliance

Quality assurance spanned pre-fabrication checks, in-process welding inspections, and final alignment surveys.

Non-destructive testing (e.g., ultrasonic or magnetic particle) was applied to critical joints. Bolted connections

were checked for torque/tension; cladding seams were inspected for weather integrity. Safety compliance included

PPE enforcement, fall-arrest systems, and emergency drills suitable for industrial steel erection.

Sustainability & Lifecycle Value

Steel’s recyclability and precise factory fabrication reduce waste compared to conventional methods.

Insulated cladding, daylighting features, and natural ventilation strategies lower operational energy.

The steel structure factory design also supports easy disassembly or reconfiguration, protecting embodied value.

Performance, Maintainability & Expansion

Rigid frames offer predictable deflection control and robust performance under wind and operational loads.

Maintenance focuses on coating inspections, fastener checks, gutter cleaning, and local touch-ups after impacts.

Because the frame is modular, future extensions can be added at gables with minimal disruption to production.

Recommended Maintenance Intervals

- Quarterly: Visual check of gutters, downpipes, and debris accumulation.

- Semi-Annual: Fastener sampling, sealant joints, and localized coating touch-ups.

- Annual: Full envelope walk-through, corrosion hotspot mapping, and drainage audit.

Cost Control, Schedule & Risk Management

Early locking of steel grades and cladding profiles reduced price volatility and lead-time risks.

Erection sequencing and crane utilization were optimized to curb standing time. Weather windows and

contingency plans safeguarded the October 2024 completion. Regular three-week look-aheads kept procurement,

fabrication, and site works synchronized.

Key Risk Controls

- Supply Chain: Dual sourcing for critical fasteners and coatings.

- Weather: Temporary waterproofing and staged cladding to protect installed work.

- Quality: Hold points for welding, bolt tensioning, and envelope water tests.

Handover Deliverables & O&M

At practical completion, the owner received a comprehensive handover package to streamline operations and warranty management.

- As-built drawings and connection schedules

- Material certificates, WPS/PQR records, and inspection reports

- Coating system datasheets and maintenance guidelines

- Operation & Maintenance manual (O&M) with inspection checklists

- Warranty documents for steelwork and envelope systems