Steel Structure Platform Project Details

A Steel Structure Platform is one of the most efficient ways to add safe, load-bearing working areas inside industrial facilities without interrupting production. This project in the Philippines delivers a high-capacity, multi-level industrial working platform designed for equipment operation, inspection, and maintenance workflows. Engineered for durability, rapid installation, and lifecycle value, the platform integrates structural steel framing, anti-slip decking, robust access systems, and comprehensive MEP routing to support 24/7 operations in a tropical, high-humidity environment.

Project Snapshot

- Location: Philippines

- Steel Usage: 450 tons

- Structure Type: Steel structure industrial working platform

- Completion Time: October 2023

Project Background & Objectives

Industrial facilities in the Philippines often face the dual challenge of expanding usable space while maintaining strict safety and uptime requirements. The client required a modular Steel Structure Platform that could be erected within an active production environment, provide high live-load capacity for process lines and maintenance crews, and enable clean routing of utilities. The solution needed to minimize foundation work, shorten on-site schedules, and offer flexibility for future expansion without extensive structural rework.

The resulting platform creates an elevated, code-compliant working environment that consolidates operations above ground level, freeing the floor for material flow and logistics. It delivers a balanced combination of stiffness, load capacity, and vibration control, while addressing corrosion protection, slip resistance, and safe access for frequent inspections and equipment replacement.

Design Concept & Structural System

Platform Layout & Functional Zoning

The platform is divided into functional bays aligned with process stations and maintenance clearances. Equipment zones feature heavier deck plates and localized stiffening, while personnel walkways use grating or light checkered plate to reduce self-weight and promote drainage. Clear aisles, turning radii, and headroom envelopes are coordinated with forklift and crane paths at ground level to avoid interference with material handling.

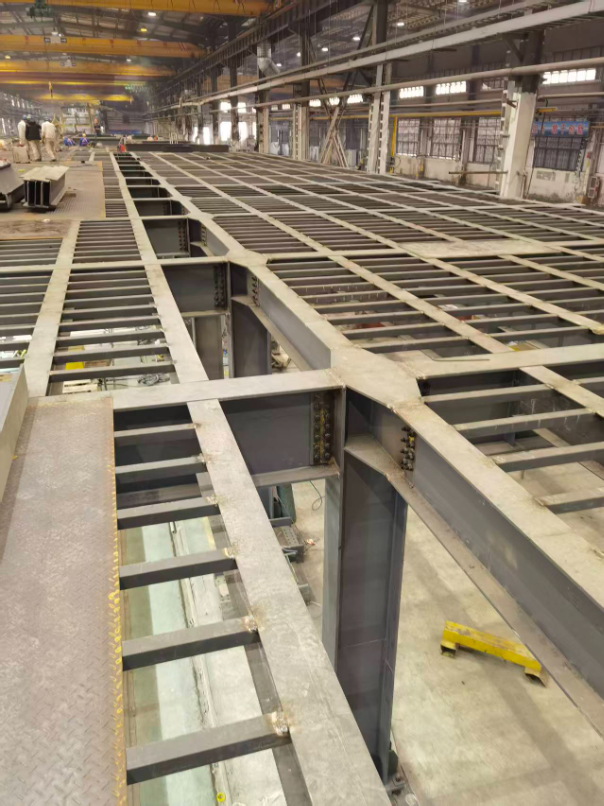

Primary & Secondary Steelwork

The primary frame consists of rolled or built-up columns and beams arranged on a regular grid to optimize repetition and speed of fabrication. Secondary members—joists, stringers, and edge angles—provide efficient load distribution to the main beams. The deck system (grating or plate) transfers loads to the secondary network while maintaining service penetrations for pipes, cable trays, and ducts. Lateral stability is achieved via a combination of vertical braced bays and plan bracing beneath the deck; where process access prohibits bracing, moment connections or knee-braces are employed to maintain stiffness without obstructing equipment.

Load Criteria & Serviceability

Design live loads are set to accommodate typical industrial activities, including personnel movement, tool carts, storage of spare parts, and equipment installation. Where concentrated loads from skids or machinery occur, local deck thickening and stiffeners are introduced to control deflection and vibration. Serviceability criteria prioritize worker comfort, instrument accuracy, and protection of sensitive equipment. Vibration response is tuned through member sizing, connection rigidity, and strategic use of diaphragms or dampers where necessary.

Seismic & Wind Considerations for the Philippines

Given the Philippines’ seismicity and typhoon exposure, the Steel Structure Platform incorporates robust lateral systems and ductile detailing. Braced frames and capacity-protected connections guide seismic forces along intended paths, while anchor bolt groups and base plates are sized for uplift and shear under combined wind-seismic scenarios. Non-structural components—handrails, MEP supports, and cable trays—use positive attachment and bracing to prevent displacement during extreme events.

Materials & Specifications

Steel Grades & Sections

Structural components use high-quality carbon steel with yield strengths selected to balance weight, stiffness, and cost. Rolled wide-flange beams, H-sections, and built-up plate girders are adopted where spans or loads demand. Cold-formed profiles may be utilized for secondary members to enhance material efficiency. All materials are traceable, with mill certificates and heat numbers recorded for quality documentation.

Decking, Grating & Floor Finishes

Deck systems include hot-dip galvanized grating for drainage and slip resistance in wet areas, and checkered plate in equipment zones requiring solid floors or fluid containment. Where noise control is important, resilient pads and composite deck solutions reduce vibration transmission. Abrasion-resistant coatings and non-slip finishes are specified for high-traffic routes, stair treads, and landings.

Corrosion Protection & Fire Safety

To suit the Philippines’ humid, coastal climate, the platform applies a multi-layer anti-corrosion system, typically comprising abrasive blast cleaning, zinc-rich primer, epoxy intermediate, and polyurethane topcoat, or hot-dip galvanizing for maximum durability. For areas with elevated fire risk, intumescent coatings provide fire resistance to protect critical load-bearing elements and extend egress time.

Fabrication & Quality Assurance

Precision Fabrication

All components are fabricated with CNC cutting, drilling, and fit-up to maintain tight dimensional tolerances. Shop assemblies are trial-fit to verify alignment, bolt hole compatibility, and interface clearances for MEP supports. Weld procedures are qualified, and consumables are controlled to ensure consistency across the 450-ton steel package.

Welding & Bolting

Welding follows qualified procedures with preheat, interpass temperature control, and documented inspection. High-strength bolts (e.g., friction-type joints in braced bays) are used in connections where slip-critical performance is required, while bearing-type bolts are adopted for standard shear connections. All bolted joints are tensioned and verified according to specified torque or turn-of-nut methods, with inspection records maintained for turnover.

Dimensional Control & Traceability

A structured inspection and test plan (ITP) governs each stage—material receipt, fabrication, surface preparation, coating, and packing. Dimensional surveys confirm camber, squareness, and hole alignment. Each piece is tagged and packed by erection sequence to minimize handling at site and accelerate installation.

Installation & Construction Methodology

Site Logistics & Pre-Erection Planning

Because the facility remained partially operational, the construction plan emphasized short shutdown windows and clean separation between active production and the erection front. Components arrived in just-in-time deliveries, with laydown areas arranged to avoid blocking plant circulation. Lift studies determined crane capacities, swing radii, and pick points to ensure safe operations under local wind conditions.

Erection Sequence

- Set out base plates and grout pads; verify anchor bolt positions.

- Erect columns and install temporary bracing to stabilize the first bay.

- Place primary beams, then secondary joists/stringers following the designated grid.

- Install bracing members and tighten connections per sequence to establish global stiffness.

- Fix decking/grating, edge angles, and toe boards; complete stair towers and ladders.

- Mount guardrails and mid-rails; install kick plates at open edges and around equipment cutouts.

- Coordinate MEP supports, cable trays, and pipe shoes; finalize penetrations and sealing.

Construction Safety & Access

Safety planning covered fall protection, controlled access zones, tag-line use for suspended loads, and lock-out/tag-out during tie-ins. Walkways were commissioned with anti-slip surfaces, uniform riser heights on stairs, and continuous handrails. Lighting levels at working height and emergency egress signage were verified before handover.

MEP, Utilities & Access Integration

Routing & Supports

The Steel Structure Platform integrates standard support details for pipe racks, cable ladders, and instrument conduits. Adjustable hangers and unistrut channels allow field fit to as-built conditions. Removable deck panels or bolted access hatches create service openings for valve maintenance and sensor replacement, minimizing downtime.

Access, Ergonomics & Safety Barriers

Stairs, platforms, and landings are arranged to limit travel distances and avoid dead-end corridors. Guardrails meet height and load requirements, with mid-rails and toe boards to prevent dropped objects. Swing gates protect pallet drop zones, and chain barriers are provided at temporary openings. Color-coded markings differentiate pedestrian paths from equipment zones.

Performance Outcomes & Client Benefits

Operational Efficiency

By elevating process equipment and maintenance routes, the platform increases floor-level throughput and simplifies line reconfiguration. The open underside improves forklift maneuvering and housekeeping, while overhead routing reduces congestion and trip hazards. Fasteners and modular connections mean equipment upgrades can be implemented with minimal hot work and short outage windows.

Reliability & Maintainability

Standardized components and clear load paths simplify inspection and repair. Drainage through grating minimizes standing water, lowering slip risk and corrosion potential. Coating systems and galvanizing extend repaint cycles—especially valuable in humid, coastal Philippine environments—thus lowering total cost of ownership.

Sustainability & Lifecycle Value

Steel’s recyclability and the platform’s modular design support future reuse and expansion. Off-site fabrication reduces waste, noise, and dust at the plant, while the lighter structural footprint minimizes foundation materials. Over the lifecycle, the platform’s durability and adaptability preserve value even as processes evolve.

Commissioning, Testing & Handover

Prior to handover, the Steel Structure Platform underwent comprehensive inspections: bolt preload verification, weld NDT sampling, coating thickness checks, and deck fastener pull tests. Load tests were performed in critical bays to validate deflection limits under simulated service loads. As-built models and drawings, material certificates, and maintenance manuals were delivered as part of the turnover dossier, enabling the client’s team to manage the asset confidently from day one.

Maintenance Strategy

Routine Inspection

A periodic inspection plan targets high-exposure areas—stair nosings, edge angles, connection nodes, base plates, and bracing gussets. Any coating damage is spot-repaired per the manufacturer’s system, and drainage points are kept clear to prevent corrosion. Vibration checks in equipment zones confirm that operating profiles remain within acceptable limits.

Predictive & Preventive Actions

Bolted joints in dynamic areas are re-torqued on a defined schedule. Where equipment changes add new point loads, the owner’s team follows a simple re-assessment checklist to verify local capacity and, if needed, add stiffeners or redistribute loads. This disciplined approach preserves performance and reduces unplanned downtime.

Customization Options for Future Projects

- Decking Choices: Open grating, checkered plate, or composite deck with acoustic layers.

- Access Systems: Spiral stairs, vertical ladders with cages, or inclined ship ladders for constrained spaces.

- Protective Systems: Hot-dip galvanizing, duplex coating systems, or specialty high-build epoxies for aggressive zones.

- Vibration Control: Tuned member sizes, diaphragms, or dampers for sensitive instruments.

- Integration: Custom pipe shoes, cable tray drops, and quick-change brackets for modular equipment.

Why Choose a Steel Structure Platform

Compared to concrete mezzanines or ad-hoc catwalks, a purpose-engineered Steel Structure Platform offers higher strength-to-weight ratio, shorter installation time, and superior adaptability. It can be expanded bay-by-bay as production grows, with minimal interruption to operations. Its standardized detailing streamlines fabrication, while its modularity future-proofs investments in fast-moving industrial environments.

Conclusion

Completed in October 2023, this Philippines industrial working platform demonstrates how a carefully engineered Steel Structure Platform can unlock vertical space, improve safety, and accelerate throughput without major civil works. The 450-ton steel package balances strength, stiffness, and maintainability, providing a durable backbone for production, utilities, and maintenance access. With robust corrosion protection, integrated MEP supports, and a maintenance plan aligned to local conditions, the platform delivers long-term performance and the flexibility to adapt to future process changes—an asset built to serve the facility for decades.