Steel Structure Factory Detail project

This case study presents a high-precision Steel Structure Factory solution engineered and delivered for a liquefied air processing plant in Malaysia, completed on time and optimized for safety, reliability, and future expansion.

Project Snapshot

| Key Metric | Detail |

|---|---|

| Location | Malaysia |

| Steel Usage | 620 tons |

| Completion Time | November 2024 |

| Main Functions | Production hall, cold-box bay, compressor station, pipe rack corridors, utilities, admin & QC, warehouse |

| Structural Concept | Portal rigid frames with crane-supporting girders, truss/pipe-rack frames, secondary purlins & girts, bracing system |

| Envelope | Insulated roof & wall systems, vapor control, daylighting skylights, corrosion-resistant coatings |

Executive Summary

The Malaysia Liquefied Air Processing Plant required a fast, clean, and precisely engineered industrial facility with rigorous safety and uptime expectations. A Steel Structure Factory configuration was selected to achieve rapid delivery, exacting tolerances for process equipment, and clear spans for overhead crane operations. The integrated scope included design, fabrication, surface protection, logistics, erection, and quality assurance, culminating in a November 2024 handover. With 620 tons of structural steel deployed across process and auxiliary buildings, the solution balances performance, constructability, lifecycle durability, and expandability.

Why a Steel Structure Factory Suits Liquefied Air Processing

Speed, Precision, and Clean Integration

Liquefied air plants depend on tightly controlled process conditions, heavy rotating equipment, and cold-box assemblies. A Steel Structure Factory approach enables high fabrication accuracy, fast site installation, and easy integration of equipment skids, pipe bridges, and utility runs. Pre-engineered members and bolted connections shorten critical-path activities while maintaining dimensional fidelity for anchor bolts and crane rail alignments.

Large Clear Spans and Crane-Ready Bays

Portal frames and truss girders create column-free areas for compressor lines, distillation columns, and cryogenic vessels. Integrated crane beams manage dynamic loads from hoisting operations, while lateral bracing ensures building stiffness during lifts and equipment positioning. This combination reduces installation conflicts and supports safe, efficient maintenance.

Adaptability and Lifecycle Value

Process plants evolve. Steel frames allow future mezzanines, platform extensions, or bay lengthening with minimal disruption. Replaceable secondary members, removable cladding modules, and standardized connection details ensure that the Steel Structure Factory can adapt to new equipment or throughput increases over its life.

Durability in Humid, Marine-Influenced Climates

Malaysia’s humidity and potential salt-laden air demand robust corrosion strategies. Factory-applied coatings and galvanizing on critical members, paired with controlled overlaps and sealed penetrations, protect the building envelope and structural system for decades of reliable service.

Functional Program and Building Layout

Production Hall & Cold-Box Bay

The production hall houses key equipment trains, electrical & instrumentation panels, and service corridors. An adjoining cold-box bay provides extra height clearance and rigorous vapor-control detailing around roof and wall interfaces, mitigating condensation risks.

Compressor Station and Utility Blocks

Dedicated compressor foundations interface with the steel superstructure via isolation details to limit vibration transfer. Utility blocks consolidate cooling water, air, nitrogen, and power systems, streamlining maintenance access while keeping hazardous zones segregated.

Pipe Racks and Interconnecting Bridges

Steel pipe racks span between process areas, designed for sustained gravity loads, thermal movements, and occasional live loads during maintenance. Modular rack bays facilitate phased installation and future line additions.

Administration, QC, and Warehouse

A compact admin and QC suite provides oversight, sampling, and documentation areas, while a warehouse with racking lanes and dock doors supports spare parts and consumables handling.

Structural System and Engineering

Primary Framing

The main buildings utilize portal rigid frames with tapered or prismatic columns and rafters sized for gravity, wind, and crane-induced dynamic effects. Cold-box zones employ taller frames and stiffened eaves to control drift and deflection. Pipe racks use moment frames or braced bents for lateral stability.

Secondary Members

Z- or C-purlins and girts support the envelope, coordinated with service penetrations and maintenance walkways. Sag rods and bridging maintain member alignment and limit lateral-torsional buckling under uplift.

Connections and Tolerances

High-strength bolt assemblies, shop-welded end plates, and slotted holes at select interfaces simplify site fit-up. Erection tolerances accommodate crane rail setting, platform interfaces, and pipe-support embeds, ensuring dimensional control across long bays.

Crane Systems

Crane runway girders, end stops, and rail clips are integrated into the frame design. Fatigue checks and local web stiffening address repetitive load cycles, while independent columns can be adopted in heavy-duty zones to decouple crane actions.

Foundations and Interfaces

Base plates and anchor bolts are coordinated with civil foundations for efficient load transfer. Grout pads and leveling techniques achieve precise column plumbness; embedded plates and sleeves anticipate handrail, platform, and MEP attachments.

Materials, Coatings, and Corrosion Protection

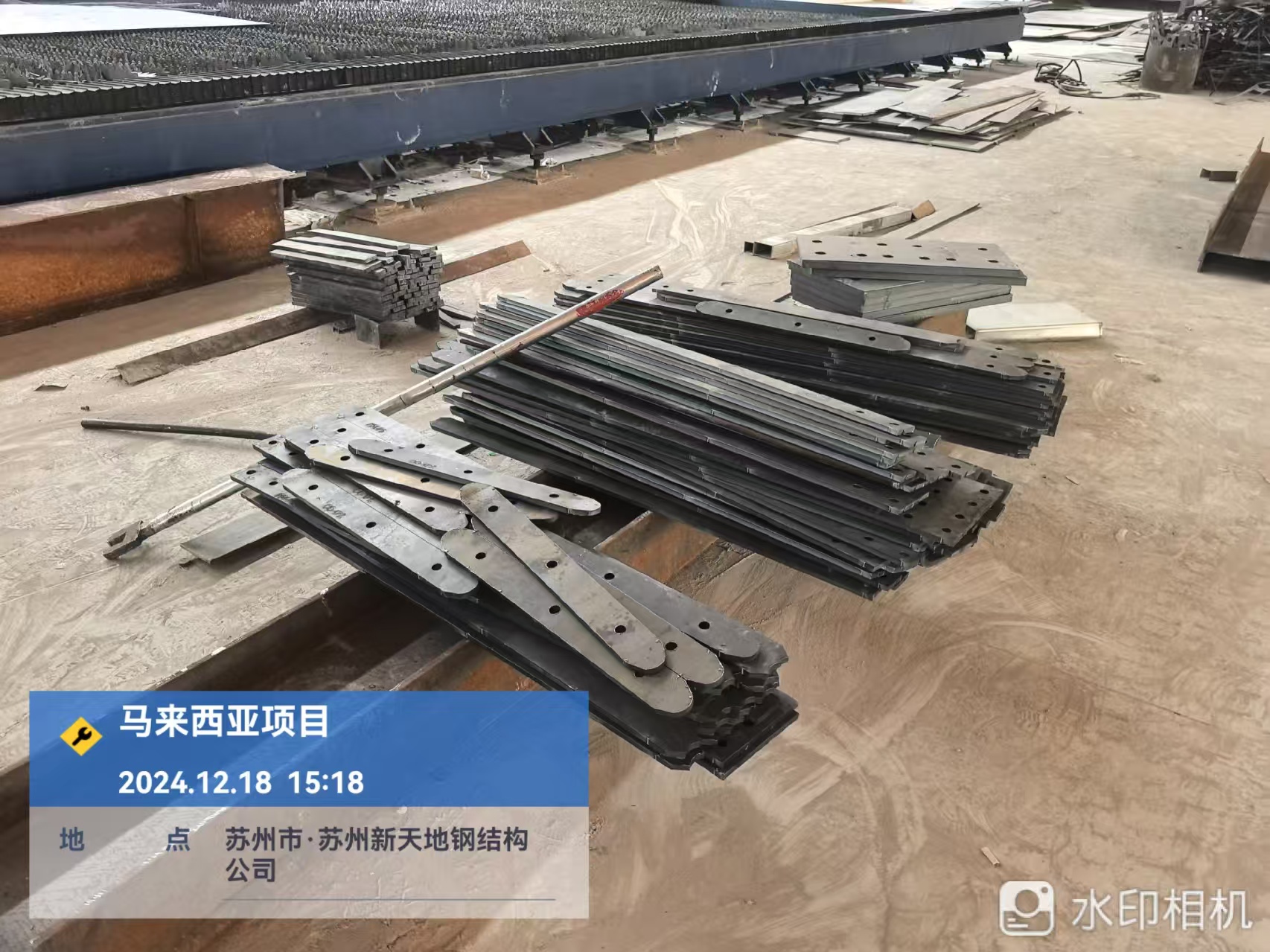

Steel Grades and Fabrication

Structural members are fabricated from standard building-grade steels suited to tropical climates and industrial service. CNC cutting, automated welding, and dimensional jigs ensure repeatability and speed across the 620-ton scope.

Surface Preparation and Coating System

Blast-cleaned surfaces receive multi-coat systems selected for humidity resistance and chemical exposure. Hot-dip galvanizing is used for pipe-rack components and external supports; stainless steel or coated carbon steel is specified at cryogenic interfaces where appropriate.

Fasteners and Accessories

Corrosion-resistant fasteners and sealed fastener lines reduce ingress at roof and wall laps. Gaskets, butyl tapes, and properly detailed flashing protect cut edges and junctions.

Building Envelope and Thermal Control

Roof and Wall Systems

Insulated sandwich panels deliver thermal continuity and indoor comfort in control rooms and maintenance bays. In process areas, vapor barriers and controlled ventilation limit condensation on steel members and services.

Daylighting and Energy Efficiency

Polycarbonate skylights and clerestories introduce safe, diffuse daylight, reducing daytime lighting demand. The roof structure can be pre-engineered for photovoltaic loading and cable routing to support future energy initiatives.

Acoustics and Weathering

Acoustic liners are included near compressor zones to temper noise. Coastal-grade coatings and drip-edge details mitigate driving rain and UV exposure, protecting both envelope and structure.

Fire Safety and Compliance

Passive Protection

Fire-resistant claddings, intumescent coatings on critical members, and compartmentation strategies protect structural integrity and enable safe egress. Fire-stopping at penetrations preserves compartment performance.

Egress, Access, and Lightning Protection

Stair towers, platforms, and marked evacuation routes are integrated into the steel layout. Lightning protection and earthing systems safeguard sensitive equipment and personnel in storm-prone conditions.

Quality Assurance, Logistics, and Erection

QA/QC in Fabrication

Weld procedures are qualified, and non-destructive testing (UT/MT/VT) is performed on critical joints. Dimensional checks verify camber, squareness, and hole alignment before dispatch.

Just-in-Time Deliveries

Sequenced shipping aligned with the erection plan reduces laydown congestion. Member identification and digital packing lists accelerate receiving and crane picks.

Erection Methodology

The sequence begins with setting gridlines and braced bays, followed by frame-by-frame lifts, temporary guying, and bolt snugging. After plumbing and full tightening, secondary members, bracing, and envelope systems are installed. Crane rails, platforms, and pipe racks complete the superstructure.

Commissioning Interface

Walkdowns with process and E&I teams confirm access clearances, platform elevations, and penetrations. As-built documentation supports turnover and operations readiness.

Schedule and Milestones

- Concept & Basis of Design: Project definition, layout zoning, and load cases.

- Detailed Engineering: Frame sizing, connection design, crane & rack integration, envelope detailing.

- Procurement & Fabrication: Mill orders, trial assemblies, coating application for offshore/humid service.

- Logistics & Site Prep: Foundation handover, anchor-bolt surveys, laydown planning.

- Erection & Envelope: Structural frames, bracing, purlins/girts, roof/wall panels, skylights.

- Fit-Out & Finalization: Platforms, stairs, crane commissioning interfaces, punch-list closeout.

- Handover: Practical completion achieved in November 2024, aligned with plant commissioning phases.

Structural Performance and Serviceability

The design balances ultimate strength with serviceability: limiting drift for equipment alignment, controlling deflection at crane girders, and checking vibration near sensitive instrumentation. Pipe racks are engineered for sustained and thermal loads with expansion allowances at strategic bays.

Sustainability and Operational Excellence

The Steel Structure Factory approach minimizes waste via standardized components and high recycling potential at end of life. Envelope insulation, daylighting, and PV-ready roofs reduce operational energy. Rainwater harvesting and segregated drainage mitigate site runoff and support utility conservation goals.

Outcomes and Measured Value

- On-time completion in November 2024 with coordinated commissioning support.

- Deployment of 620 tons of steel across production, rack, and utility structures.

- Large clear spans for safe equipment handling and crane operations.

- Future-ready bays and modular pipe rack capacity for throughput upgrades.

- Coating and detailing strategy tailored to Malaysia’s humid, coastal-influenced climate.

Maintenance and Lifecycle Planning

The structure is designed for straightforward inspection and upkeep: accessible bolted connections, walkable roof routes, documented coating systems, and replaceable panel modules. Planned inspections—covering corrosion checkpoints, fastener torque verifications, and rail alignment—extend service life and safeguard uptime.

Frequently Asked Questions

How does a Steel Structure Factory minimize plant downtime during upgrades?

Steel frames simplify phased works: additional platforms, mezzanines, or pipe-rack bays can be installed with localized isolation, reducing global shutdown needs. Standardized nodes and connection details accelerate modifications.

What controls condensation at cold-box interfaces?

A coordinated envelope—insulation, vapor barriers, airtight penetrations, and controlled ventilation—prevents moisture migration toward cold surfaces. Attention to roof laps, flashing, and pipe sleeves is critical.

How are crane impacts addressed structurally?

The design checks repeated wheel loads, lateral surge, and uplift at runway beams. Stiffeners, web doublers, and bracing uprights are included where required, with serviceability limits to protect instrumentation and finishes.

What corrosion strategy suits Malaysia’s climate?

A combined approach—galvanizing for exposed racks and supports, marine-grade coating systems for frames, sealed fastener lines, and drainage-conscious detailing—delivers durable performance in humid conditions.

Plan Your Next Steel Structure Factory

If you are planning a liquefied air, industrial gas, or specialty-chemicals facility, our Steel Structure Factory solutions deliver speed, safety, and scalability. Contact our engineering team to review layouts, crane requirements, and expansion pathways tailored to your site in Malaysia or abroad.