Industrial construction is undergoing a fundamental shift. Rising labor costs, tighter project schedules, and increasing demands for quality and sustainability are forcing developers and contractors to rethink traditional building methods. In this context, prefab industrial construction has emerged as a transformative approach—particularly through the use of prefabricated steel structures.

Unlike conventional on-site construction, prefab steel systems rely on off-site manufacturing, precision engineering, and controlled assembly processes. This method is redefining how factories, warehouses, logistics centers, and industrial plants are designed and delivered, offering faster timelines, higher consistency, and improved cost control.

This article explores why prefab steel structures are reshaping industrial construction, focusing on modern construction technology, preassembly strategies, and the long-term value they deliver to industrial projects.

Understanding Prefab Industrial Construction

Prefab industrial construction refers to a construction methodology in which major structural components are manufactured in a controlled factory environment and then transported to the job site for final assembly. In steel-based systems, this typically includes columns, beams, trusses, floor systems, wall panels, and connection elements.

Instead of building everything piece by piece on site, prefab construction emphasizes preassembly, where components or modules are partially or fully assembled before delivery. This approach reduces on-site complexity and shifts much of the work to environments where quality, safety, and efficiency can be better managed.

For industrial projects—where scale, load capacity, and precision matter—steel is the ideal material for prefab systems.

The Role of Modern Construction Technology

The rapid adoption of modern construction tech is a key driver behind the success of prefab steel structures. Digital tools and advanced manufacturing techniques allow industrial buildings to be designed and produced with unprecedented accuracy.

Key technologies supporting prefab industrial construction include:

- Building Information Modeling (BIM) for clash detection and optimized structural design

- CNC cutting and robotic welding for consistent fabrication quality

- Digital shop drawings that integrate directly with production lines

- Simulation tools to plan lifting, logistics, and erection sequences

By integrating design and manufacturing through digital workflows, prefab steel construction minimizes errors that traditionally occur between engineering and on-site execution.

Speed: Accelerating Industrial Project Timelines

One of the most compelling reasons industrial developers adopt prefab steel structures is speed. Traditional construction often follows a linear sequence—foundation, structure, enclosure, and finishing—each phase dependent on the completion of the previous one.

Prefab industrial construction enables parallel workflows:

- Steel components are fabricated while foundations are being prepared

- Preassembled sections reduce on-site installation time

- Weather-related delays are minimized due to off-site production

As a result, industrial facilities can be completed weeks or even months faster, allowing owners to bring operations online sooner and reduce time-to-revenue.

Preassembly and Its Impact on Quality

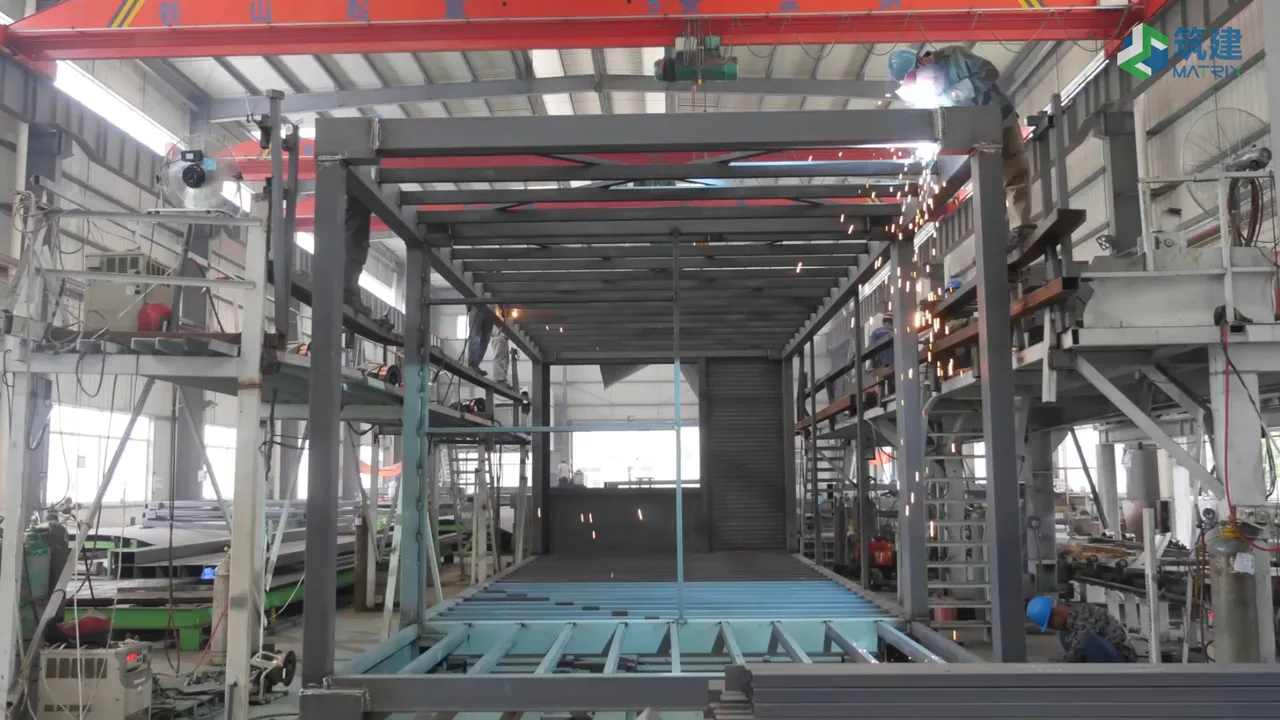

Preassembly is a defining feature of prefab steel construction. Instead of assembling hundreds of individual components on site, sections of the structure are preassembled under controlled factory conditions.

This approach delivers several quality advantages:

- Consistent welding quality and dimensional accuracy

- Reduced risk of improper connections

- Improved alignment of structural elements

- Lower dependency on variable on-site labor skills

For industrial buildings that must support heavy machinery, cranes, or multi-level operations, structural accuracy is critical. Preassembly ensures that tolerances are met before components ever reach the site.

Cost Efficiency Beyond Initial Construction

While prefab steel systems may appear comparable—or slightly higher—in upfront material costs, their overall cost efficiency becomes clear when considering the full project lifecycle.

Prefab industrial construction helps control costs by:

- Reducing on-site labor requirements

- Minimizing rework and material waste

- Shortening construction schedules

- Lowering indirect costs such as supervision and equipment rental

Additionally, steel structures offer long-term savings through durability, adaptability, and lower maintenance requirements compared to many traditional construction methods.

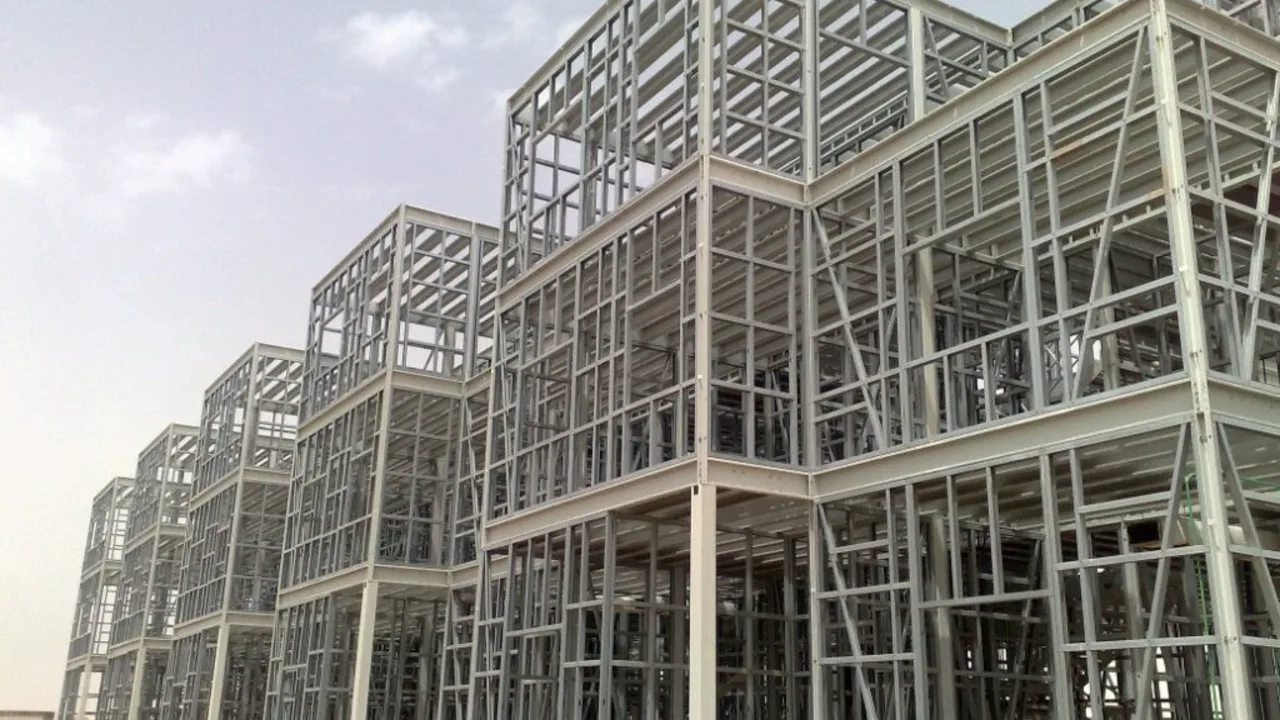

Flexibility and Scalability for Industrial Growth

Industrial operations rarely remain static. Production lines expand, storage needs increase, and processes evolve. Prefab steel structures are inherently suited to this reality.

Because steel systems are modular, they allow:

- Future extensions without major demolition

- Vertical or horizontal expansion

- Reconfiguration of internal layouts

- Integration of new equipment or mezzanine platforms

This flexibility makes prefab industrial construction a strategic choice for businesses planning long-term growth or phased development.

Sustainability and Resource Efficiency

Sustainability is becoming a core consideration in industrial construction. Prefab steel structures align well with environmental objectives due to their efficient use of materials and reduced site impact.

Key sustainability benefits include:

- Lower material waste through precision fabrication

- Reduced transportation and on-site emissions

- High recyclability of structural steel

- Compatibility with energy-efficient building envelopes

By shifting production to optimized factory settings, prefab construction supports more responsible use of resources without compromising structural performance.

Safety Advantages of Prefab Steel Construction

Industrial construction sites are inherently high-risk environments. Prefab methods significantly improve safety performance by transferring much of the work away from the site.

Safety benefits include:

- Less work at height during erection

- Reduced congestion on site

- Fewer manual handling activities

- Controlled factory conditions for hazardous operations

Improved safety not only protects workers but also reduces delays, insurance costs, and project risk exposure.

Applications Across Industrial Sectors

Prefab steel structures are now widely adopted across multiple industrial sectors, including:

- Manufacturing plants and workshops

- Logistics and distribution centers

- Warehouses and cold storage facilities

- Energy and utility infrastructure

- Automotive and heavy equipment facilities

Their ability to accommodate large spans, heavy loads, and specialized operational requirements makes them suitable for diverse industrial applications.

Integrating Prefab Systems into Industrial Construction Strategy

To fully realize the benefits of prefab industrial construction, developers must integrate prefab thinking early in the project lifecycle. This includes aligning design decisions, logistics planning, and construction sequencing around prefab principles.

Working with experienced partners in prefabricated steel structure systems ensures that engineering, fabrication, and installation are optimized as a single, coordinated process rather than disconnected phases.

When prefab strategies are embedded from the outset, industrial projects achieve higher predictability, better quality, and stronger long-term performance.

Conclusion: The Future of Industrial Construction

Prefab industrial construction is no longer a niche approach—it is becoming the standard for modern industrial development. Driven by advances in construction technology, the efficiency of preassembly, and the inherent strengths of steel, prefab systems offer a smarter way to build industrial facilities.

As industrial demands continue to evolve, prefab steel structures will play a central role in delivering faster, safer, and more adaptable construction solutions—positioning them at the forefront of the industry’s transformation.