In today’s fast-paced industrial and commercial construction environment, speed is no longer just a scheduling advantage—it is a strategic requirement. Delays in steel erection can quickly escalate labor costs, disrupt downstream trades, and jeopardize overall project delivery. This is why steel preconstruction engineering has become a critical success factor for modern steel projects.

Rather than solving problems on site, pre-construction engineering shifts critical decision-making to the early project stage. Through detailed planning, coordination, and digital modeling, project teams can dramatically reduce steel installation time while improving safety, quality, and cost control. This article explains how steel preconstruction engineering works, the role of BIM modeling, and why early engineering decisions directly translate into faster steel installation.

What Is Steel Preconstruction Engineering?

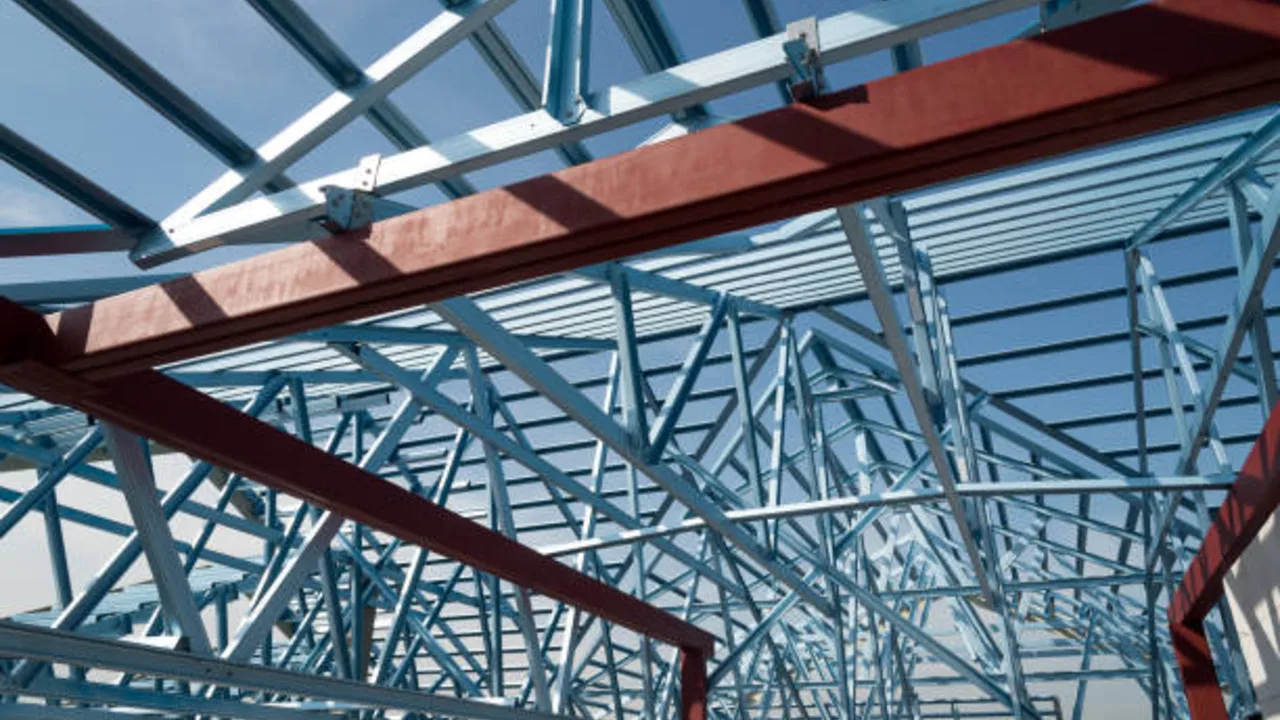

Steel preconstruction engineering is the comprehensive technical preparation process carried out before steel fabrication and on-site erection begin. It integrates structural analysis, connection design, shop drawing development, constructability review, erection sequencing, and coordination with other building systems.

Unlike traditional workflows—where many issues are addressed only after steel arrives on site—preconstruction engineering anticipates challenges in advance. By resolving design conflicts, optimizing connection details, and planning erection logic early, steel projects become more predictable and significantly faster to install.

Why Steel Installation Delays Commonly Occur

Steel installation delays are rarely caused by erection crews alone. In most cases, delays originate from insufficient early-stage planning. Common causes include:

- Incomplete or unclear shop drawings

- Poorly coordinated steel-to-steel or steel-to-concrete connections

- Design clashes between steel, MEP, and architectural systems

- Unplanned erection sequences and crane logistics

- Late design revisions or missing fabrication information

Steel preconstruction engineering directly targets these issues, eliminating uncertainty before steel reaches the job site.

The Role of BIM Modeling in Steel Preconstruction Engineering

BIM modeling is one of the most powerful tools in steel preconstruction engineering. A detailed 3D steel model allows engineers, fabricators, and contractors to visualize the entire structure before fabrication begins.

Through BIM, project teams can detect clashes between steel members and other systems, verify spatial clearances, and validate constructability. This digital coordination ensures that steel components fit precisely during installation, reducing on-site modifications and downtime.

Key BIM Benefits for Faster Steel Installation

- Early clash detection with MEP and architectural elements

- Accurate shop drawings generated directly from the model

- Clear visualization of erection sequences and crane paths

- Reduced field rework and installation interruptions

By resolving coordination issues digitally, BIM modeling significantly accelerates steel installation and improves overall project flow.

Optimized Connection Design and Standardization

Connection design plays a decisive role in steel installation speed because connections are the most labor-intensive and coordination-sensitive elements of a steel structure. Even when primary members are accurately fabricated, poorly detailed or overly complex connections can create bottlenecks during erection. Common issues include misaligned bolt holes, unclear weld specifications, excessive connection types, or tolerances that are difficult to achieve on site. These problems often lead to field adjustments, additional welding, temporary fixes, and repeated inspections—each of which directly extends steel installation time.

Steel preconstruction engineering addresses these challenges by prioritizing optimized and standardized connection design from the earliest project stages. Rather than treating connections as secondary details, engineers analyze load paths, erection sequences, and fabrication capabilities to develop connection solutions that balance structural performance with constructability. This ensures that each connection type is not only structurally sound but also practical to fabricate, transport, and install.

Standardization is a key principle in this process. Where possible, engineers design repeatable connection types that can be applied across multiple locations within the steel structure. By reducing the number of unique connection details, fabrication becomes more efficient, shop drawing complexity is minimized, and erection crews become familiar with each connection type early in the installation process. This familiarity allows crews to work faster, with fewer errors and less need for on-site interpretation.

Optimized connection design also improves fabrication accuracy. Standardized bolt patterns, weld sizes, and plate geometries enable consistent shop production and reduce the likelihood of dimensional deviations. When steel components arrive on site with uniform, clearly defined connections, installation proceeds smoothly without the need for rework or corrective measures.

In addition, clear and well-documented connection detailing significantly reduces inspection delays. Inspectors can quickly verify compliance when connection types are consistent and clearly specified, avoiding repeated clarifications or redesign requests. This contributes to a predictable erection workflow and ensures consistent quality throughout the steel structure.

Ultimately, optimized and standardized connection design transforms connections from a common source of delay into a productivity driver. By integrating connection engineering into the broader steel preconstruction engineering strategy, projects achieve faster installation, improved quality control, and a safer, more efficient erection process.

Erection Sequencing and Crane Planning

Another major advantage of steel preconstruction engineering is the development of a precise erection sequence. Instead of reacting to site conditions, engineers plan the order of installation in advance.

This planning considers structural stability, temporary bracing requirements, crane reach, lifting capacity, access routes, and site constraints. As a result, steel installation proceeds smoothly with minimal crane repositioning and reduced idle time.

Well-planned erection sequencing is one of the most effective ways to shorten overall steel installation duration.

Fabrication Accuracy and Prefabrication Strategy

Preconstruction engineering ensures that steel members are fabricated to exact dimensions and tolerances. Accurate prefabrication eliminates the need for cutting, drilling, or rework on site—activities that commonly slow down steel installation.

In many projects, assemblies such as beams with connections, bracing modules, or platform frames are prefabricated as larger units. These assemblies reduce the number of individual lifts required and speed up on-site installation.

Just-in-Time Delivery and Site Logistics

Detailed preconstruction planning also supports just-in-time delivery strategies. Steel components are delivered to the site in the exact sequence required for installation.

This approach minimizes on-site storage congestion, reduces material handling, and allows erection crews to install steel immediately upon delivery. Efficient logistics planning directly contributes to faster installation and improved site safety.

Reducing On-Site Labor and Safety Risks

Faster steel installation is closely linked to improved safety performance. Extended erection periods increase exposure to working-at-height risks, heavy lifting operations, and site congestion.

By reducing installation time through steel preconstruction engineering, projects lower total labor hours on site and reduce accident exposure. Clear installation plans, standardized details, and coordinated workflows create a safer working environment for erection crews.

Integration Between Engineering and Installation Teams

Effective steel preconstruction engineering requires close collaboration between engineers, fabricators, and installation teams. When erection crews are involved early, their practical experience informs connection design, lifting strategies, and sequencing decisions.

This integration ensures that engineering solutions are not only structurally sound but also practical, efficient, and realistic to execute on site.

Applications That Benefit Most from Preconstruction Engineering

Steel preconstruction engineering delivers the greatest value in projects with tight schedules, complex geometry, or large steel quantities, including:

- Industrial factories and manufacturing plants

- Warehouses and logistics distribution centers

- Steel structure working platforms and mezzanines

- Commercial buildings with fast-track delivery requirements

- Large-span steel structure systems

In these projects, early-stage engineering directly supports faster erection of steel structure building construction while maintaining high quality and safety standards.

Cost and Schedule Advantages of Early Engineering

Reducing steel installation time also produces measurable cost savings. Shorter erection periods lower labor costs, reduce crane rental durations, and minimize schedule-related penalties.

From a broader perspective, faster steel installation allows follow-on trades to begin earlier, compressing the overall construction schedule and improving project return on investment.

Conclusion: Engineering First, Build Faster

Steel installation speed is not determined on site—it is decided during the preconstruction phase. Steel preconstruction engineering transforms steel projects by resolving complexity early, optimizing fabrication and erection strategies, and eliminating avoidable delays.

By leveraging BIM modeling, standardized connection design, and detailed erection planning, project teams can significantly reduce steel installation time while improving safety, accuracy, and overall project performance. For modern steel construction, engineering first is the key to building faster, safer, and smarter.