The Steel Structure Industrial working platform represents a key advancement in modern industrial engineering. Built to accommodate a wide range of functional requirements, these platforms are recognized for their flexibility in design, efficiency in assembly, and strength in performance. In the modern era, where efficiency and adaptability are essential for industrial operations, steel-based platforms have become the preferred choice across factories, warehouses, storage facilities, and production centers.

This comprehensive guide explores the features, advantages, classifications, and applications of the Steel Structure Industrial working platform, explaining why it has become indispensable in modern construction and manufacturing environments.

Introduction to Steel Structure Industrial Working Platforms

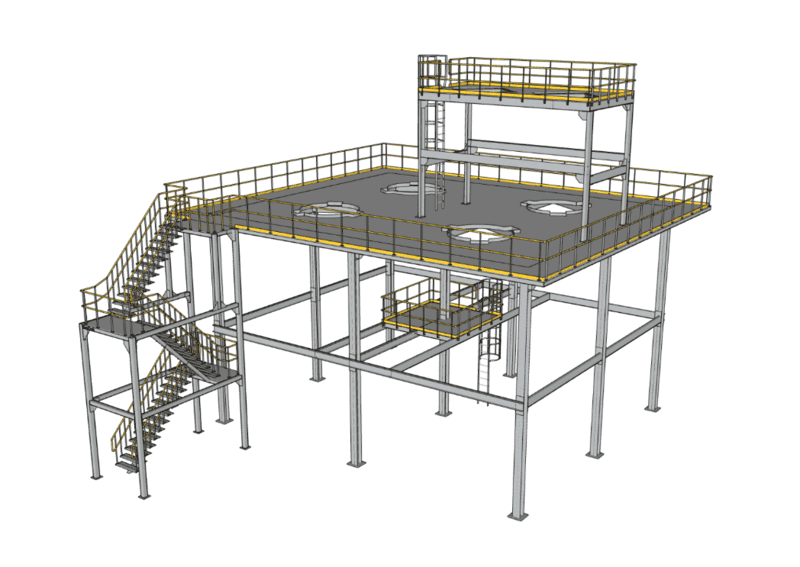

A Steel Structure Industrial working platform is essentially a multifunctional elevated structure that provides space for operations, storage, maintenance, or auxiliary work. Unlike traditional platforms that may rely on concrete or wood, the steel structure alternative is designed with modular components, allowing for flexibility, quick installation, and cost efficiency.

The growing demand for industrial efficiency has led to the widespread use of steel platforms in various sectors. Their modular and adjustable nature makes them particularly valuable in industries with evolving needs, such as logistics, heavy machinery, automotive production, and warehousing.

Key Advantages of Steel Structure Industrial Working Platforms

The advantages of a Steel Structure Industrial working platform are both practical and strategic. These benefits have driven the adoption of steel platforms worldwide.

1. Flexibility in Shape and Design

One of the standout advantages is flexible design adaptability. Steel structures can be engineered to match diverse topographies and site-specific requirements. This adaptability ensures that businesses can design platforms based on operational flow, production requirements, or storage needs.

For example, in a warehouse with uneven ground or complex machinery layouts, a Steel Structure Industrial platform can be tailored to integrate seamlessly with the existing environment.

2. Quick and Easy Assembly

The prefabricated nature of steel components allows for rapid on-site assembly. Unlike traditional construction methods that take weeks or months, steel platforms can be installed in a fraction of the time. The bolted connections, modular beams, and prefabricated panels enable easy installation and future modifications.

This speed of construction is especially valuable in scenarios such as urgent facility expansions or temporary operations where downtime must be minimized.

3. Strength and Durability

The Steel Structure Industrial platform is designed to withstand significant loads and stresses. Whether it is used to support heavy machinery, store bulk materials, or create elevated workspaces, the steel structure ensures durability and long service life.

Steel, being a high-strength material, offers excellent resistance to deformation and fatigue, making it ideal for heavy-duty industrial environments.

4. Recyclability and Sustainability

Modern industries increasingly focus on sustainability. Steel is 100% recyclable, making the Steel Structure Industrial platform an eco-friendly solution. At the end of its service life, steel components can be dismantled, repurposed, or recycled without losing strength or quality.

This not only reduces environmental impact but also aligns with global sustainability goals.

Classification of Steel Structure Industrial Working Platforms

Another major advantage of these platforms is their diverse classification system, allowing businesses to choose the type that best suits their functional needs.

1. Based on Location and Usage

- Room Platform: Designed for enclosed or indoor environments, often used for storage, assembly lines, or light operations.

- Outdoor Platform: Constructed to withstand external environmental conditions such as wind, rain, and temperature variations, commonly seen in construction or heavy industrial yards.

2. Based on Load-Bearing Capacity

- Static Load Platform: Primarily intended for storage or light operations where the load remains constant.

- Dynamic or Heavy-Duty Platform: Built to endure heavy machinery, moving loads, and rigorous industrial operations.

3. Based on Structural Support Method

- Independent Column Support: Uses strong vertical steel columns to bear the entire load of the platform, offering maximum independence and stability.

- Wall-Supported Platform: One side of the platform is anchored to the building wall, while the other is supported by columns, saving material and space.

- Tripod or Bull’s Leg Support: A simple design often used as a temporary or lightweight operation platform, safety channel, or maintenance access structure.

These classifications ensure that the Steel Structure Industrial platform can be customized for a wide range of operational demands.

Functional Applications of Steel Structure Industrial Platforms

The use of Steel Structure Industrial platforms has expanded significantly in modern industry. Below are the key areas of application.

1. Warehousing and Logistics

In warehouses, these platforms create multi-level storage solutions, allowing businesses to maximize vertical space. Instead of expanding floor areas, companies can double or triple their storage capacity through modular platforms.

2. Manufacturing and Production Facilities

Production lines often require auxiliary spaces for tools, machinery, or operator access. Steel Structure Industrial platforms provide elevated walkways, assembly areas, and spaces for equipment that improve workflow efficiency.

3. Maintenance and Safety Platforms

In heavy industries, machinery often requires elevated maintenance. Platforms designed with railings and safety features provide secure access points, reducing risks during routine maintenance or inspections.

4. Temporary and Emergency Use

Due to their easy assembly, these platforms are also used in emergency reconstruction projects or temporary facilities during large-scale industrial activities.

Design Considerations in Steel Structure Industrial Platforms

Designing a Steel Structure Industrial platform requires careful planning to ensure safety, efficiency, and cost-effectiveness.

Structural Load Requirements

Engineers must evaluate static and dynamic loads, including the weight of machinery, personnel, and stored goods. Overestimating load capacity can unnecessarily increase costs, while underestimating it poses safety hazards.

Safety and Compliance

Safety standards and local building codes must be strictly followed. Guardrails, anti-slip flooring, fire-resistant coatings, and proper lighting are crucial in platform design.

Modularity and Future Expansion

A good Steel Structure Industrial platform is designed with adaptability in mind. Future expansions, additional levels, or reconfiguration should be possible without dismantling the entire structure.

Cost and Efficiency

While steel platforms may have a higher initial cost compared to wood or concrete, their durability, recyclability, and reduced maintenance expenses make them a cost-effective long-term solution.

Advantages Over Traditional Construction

Compared to concrete or wooden platforms, the Steel Structure Industrial platform offers several key advantages:

- Faster installation due to prefabricated assembly.

- Higher strength-to-weight ratio, allowing for lighter structures with greater load capacity.

- Superior fire resistance when combined with protective coatings.

- Ease of relocation, since steel platforms can be dismantled and reinstalled elsewhere.

- Better integration with modern automation and smart industrial layouts.

These features make steel the material of choice in modern industrial infrastructure.

Future Trends in Steel Structure Industrial Platforms

With the continuous development of technology, the Steel Structure Industrial platform is evolving to meet the demands of Industry 4.0.

- Integration with Smart Systems: Platforms designed to support automated machinery, conveyor belts, and robotic systems.

- Eco-Friendly Coatings: Advanced anti-corrosion and fireproof coatings that extend lifespan and reduce environmental impact.

- Hybrid Structures: Combination of steel with lightweight composite materials to further enhance strength and efficiency.

- Modular Prefab Solutions: Growing demand for portable and reconfigurable steel platforms that can adapt to multiple industrial sites.

The Steel Structure Industrial working platform is far more than just an elevated structure—it is a modern engineering solution designed for adaptability, efficiency, and sustainability. From flexible design to quick assembly, from load-bearing strength to recyclability, these platforms embody the principles of modern industrial construction.

As industries continue to demand efficiency, adaptability, and sustainability, the Steel Structure Industrial platform will remain a cornerstone of warehouse management, manufacturing facilities, and industrial projects worldwide.

By choosing steel, businesses are investing in durability, safety, and future-ready infrastructure, ensuring that operations remain efficient, safe, and competitive for decades to come.