Project Overview

The Paraguay Warehouse Project is a practical example of how standardized steel structure systems can be applied to meet modern industrial storage and logistics needs in South America. Designed as a steel structure warehouse using a standardized portal rigid frame structure, this project focuses on structural efficiency, construction speed, and long-term operational reliability.

With a total building area of 1,080 square meters and a steel consumption of 25.34 tons (excluding colored panels), the warehouse is engineered to balance material optimization with structural safety. The project reflects a clear demand from Paraguayan industrial and commercial sectors for durable, cost-effective warehouse solutions that can be delivered and erected efficiently.

Project Location and Local Context

Located in Paraguay, the warehouse is designed with regional conditions in mind. Paraguay’s growing logistics, agricultural processing, and light manufacturing sectors require storage facilities that can handle fluctuating loads, seasonal inventory changes, and future expansion.

Steel structure warehouses are particularly suitable for this environment due to their adaptability to different site conditions, resistance to weather variations, and ability to support large, column-free interior spaces. The portal rigid frame system allows the structure to perform reliably under local wind and load requirements while maintaining a clean and functional architectural profile.

Building Area and Structural Scope

The total building area of 1,080 m² provides ample space for warehousing operations such as bulk storage, palletized goods, or equipment housing. The 25.34 tons of structural steel, calculated without colored panels, highlights an optimized design approach where material usage is carefully controlled without compromising strength or service life.

This balance is achieved through standardized structural members, rational column spacing, and efficient roof and wall framing systems. The result is a warehouse that offers high load-bearing capacity while remaining economical in fabrication, transportation, and installation.

Steel Structure Type: Portal Rigid Frame System

The core of this project is its standardized portal rigid frame structure, one of the most widely used systems for industrial warehouses worldwide. This structural type is characterized by rigid connections between columns and beams, forming a stable frame that can span large widths without intermediate supports.

Key advantages of the portal rigid frame system in this project include:

- Large clear spans, allowing flexible interior layouts and efficient material handling

- Structural stability, suitable for industrial loads and long-term use

- Simplified fabrication, using standardized steel sections

- Fast on-site assembly, reducing construction time and labor costs

This system is especially effective for warehouses in developing and emerging markets, where construction speed and cost control are critical decision factors.

Design Philosophy and Engineering Considerations

The design of the Paraguay Warehouse Project emphasizes practicality and scalability. From an engineering standpoint, the structure is developed to ensure:

- Accurate load calculation for roof, wind, and operational demands

- Optimized steel section selection to minimize excess weight

- Compatibility with common cladding systems and accessories

- Ease of future modification or extension

Standardization plays a key role in this approach. By using proven structural configurations, the project reduces design complexity while maintaining predictable performance during fabrication and installation.

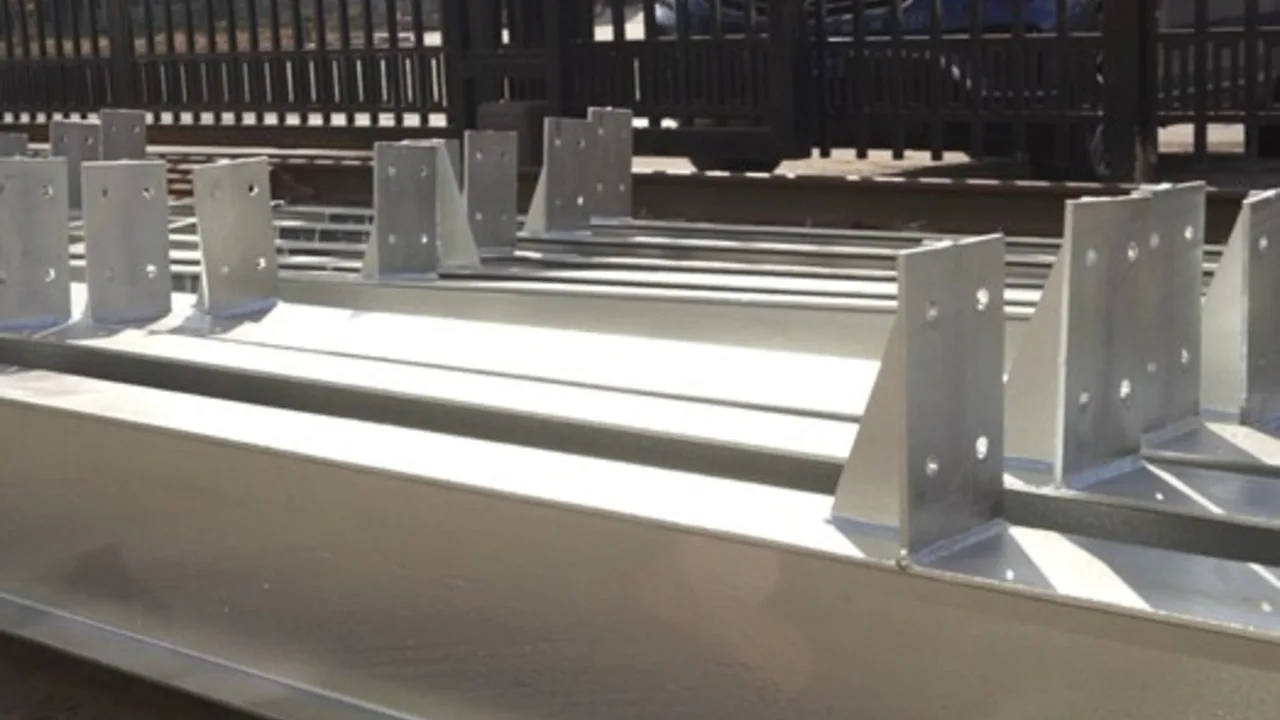

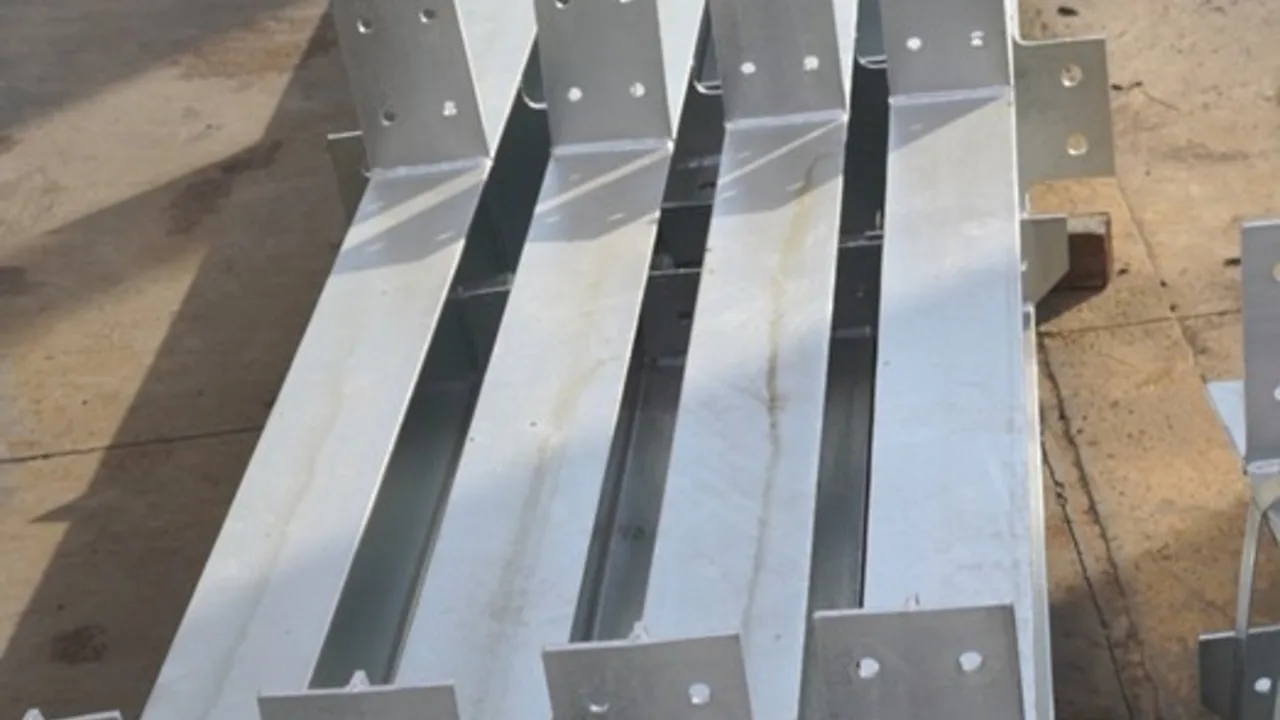

Fabrication and Construction Efficiency

One of the major strengths of steel structure warehouses is the ability to prefabricate most components off-site. For this project, steel columns, beams, and secondary members are manufactured under controlled factory conditions, ensuring consistent quality and dimensional accuracy.

Once delivered to site in Paraguay, the structure can be assembled rapidly using bolted connections. This construction method minimizes on-site welding, reduces weather-related delays, and shortens the overall project timeline. For warehouse operators, this means earlier commissioning and faster return on investment.

Functional Use and Application

The completed steel structure warehouse is suitable for a wide range of applications, including:

- General logistics and distribution storage

- Agricultural product warehousing

- Industrial raw material storage

- Equipment and machinery housing

The clear-span interior and robust structural frame allow the space to be adapted as operational needs evolve. Racking systems, mezzanines, or specialized equipment can be integrated without major structural modifications.

Long-Term Value and Performance

Beyond initial construction, the Paraguay Warehouse Project is designed for long-term performance. Steel structures offer excellent durability, low maintenance requirements, and strong resistance to deformation over time. When combined with appropriate corrosion protection and quality cladding systems, the warehouse can serve reliably for decades.

Additionally, the modular nature of the portal rigid frame system allows for future expansion. Additional bays can be added with minimal disruption, making the warehouse a scalable asset that grows alongside the business.