Steel Structure Factory Project Overview

Located in Huanggang, the Steel Structure Factory Project represents a major leap in industrial innovation and modern manufacturing. Spanning 100,800㎡, the facility integrates advanced architectural design with high-strength steel frameworks to create a future-ready production hub for home appliances. This large-scale industrial complex highlights how steel structure technology can enhance productivity, safety, and long-term operational efficiency in the modern manufacturing sector.

Project Highlights

The Huanggang Steel Structure Factory covers an expansive 100,800㎡ and utilizes over 4,200 tons of structural steel, underscoring its robust engineering and heavy-duty industrial performance. Classified as a steel structure factory, the project combines the efficiency of prefabricated construction with the precision required for high-volume appliance production. Every element of the design— from load-bearing frames to roof systems— is optimized for stability, durability, and low maintenance, ensuring that the facility can support continuous, large-scale operations.

Unlike conventional factories, this development merges industrial-grade construction standards with modern environmental and energy-saving concepts. By leveraging the proven reliability of steel frameworks, the project guarantees long-term structural safety while meeting the stringent requirements of industrial manufacturing environments.

Importance of Steel Structure in Modern Factories

The Huanggang facility demonstrates why steel structure technology is becoming the preferred choice for industrial and production buildings:

- Strength and Durability – High-strength Q355B/S355JR steel ensures excellent load-bearing capacity and resistance to vibration from heavy machinery.

- Safety and Stability – Steel’s resilience against seismic activity and extreme weather provides operational security.

- Cost Efficiency – Prefabricated components reduce on-site labor costs and long-term maintenance expenses.

- Design Flexibility – Large column-free spaces improve layout efficiency for assembly lines, logistics, and future equipment expansion.

Through this combination of benefits, the Huanggang Steel Structure Factory becomes a model for sustainable, high-performance industrial construction.

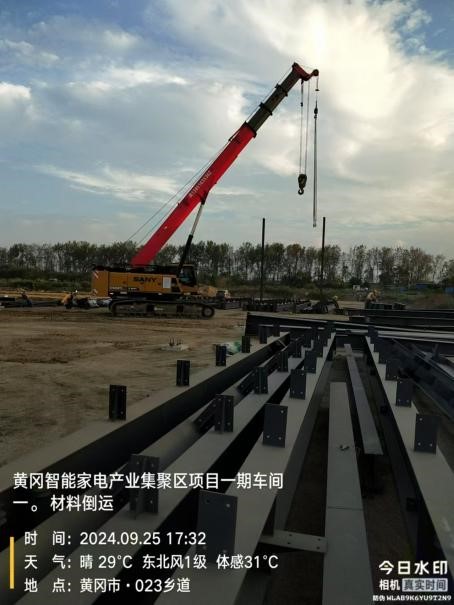

Advanced Engineering and Construction

The factory’s construction integrates modular prefabrication and precision assembly, using 4,200 tons of steel components fabricated off-site. This approach not only accelerates construction schedules but also minimizes material waste and guarantees consistency in quality.

The internal layout is designed with optimized process flow for home appliance production— from component storage and assembly to packaging and distribution. Wide-span steel trusses create uninterrupted workshop spaces, enabling efficient equipment placement and material handling. The use of energy-efficient wall panels and insulated roofing systems ensures comfortable indoor environments and reduces energy consumption.

Built under industrial-grade design standards, the factory structure follows rigorous specifications for load, vibration control, and thermal performance, ensuring long-term reliability even under high operational demands.

Environmental and Energy Benefits

Steel’s recyclability and low environmental footprint make it a cornerstone of green industrial construction. In this project, recyclable steel materials and prefabricated assembly reduce construction waste and carbon emissions.

The building is also equipped to integrate renewable energy systems such as rooftop solar panels and smart ventilation for temperature regulation. These features align with China’s national goals for green manufacturing and ESG compliance, positioning the Huanggang factory as a model for sustainable industrial development.

Production Function and Purpose

Once completed, the Huanggang Steel Structure Factory will serve as a comprehensive home appliance manufacturing base. The facility includes:

- Main production halls for assembly and testing

- Storage and logistics centers for raw materials and finished goods

- Quality control laboratories for product testing and certification

- Administrative and R&D offices integrated into the same steel structure framework

This integrated design enhances productivity, shortens supply chains, and supports the factory’s long-term adaptability to evolving production technologies.

Project Timeline and Outlook

The factory is on schedule for completion in 2025, symbolizing Huanggang’s rise as a key industrial hub in central China. Upon completion, it will stand as a benchmark for modern steel structure factory engineering, combining industrial strength, intelligent manufacturing systems, and eco-friendly design.

This achievement goes beyond construction— it represents a vision of future-ready manufacturing, where steel structure technology drives efficiency, sustainability, and innovation.

Future Impact

The success of the Huanggang Steel Structure Factory is expected to influence future industrial facility designs nationwide. By proving that steel structures can deliver superior efficiency and durability for advanced manufacturing, it paves the way for more factories adopting similar frameworks for electronics, automotive parts, and high-tech products.

In essence, this project demonstrates how steel structure factories can redefine the future of industrial production— combining strength, precision, and sustainability to build smarter and greener manufacturing environments.