Leading Steel Structure Manufacturer

Choosing the right steel structure manufacturer plays a major role in the success, efficiency, and long-term reliability of any industrial or commercial building project. Our engineering team focuses on precision fabrication, optimized load performance, and solutions tailored to each client’s operational needs.

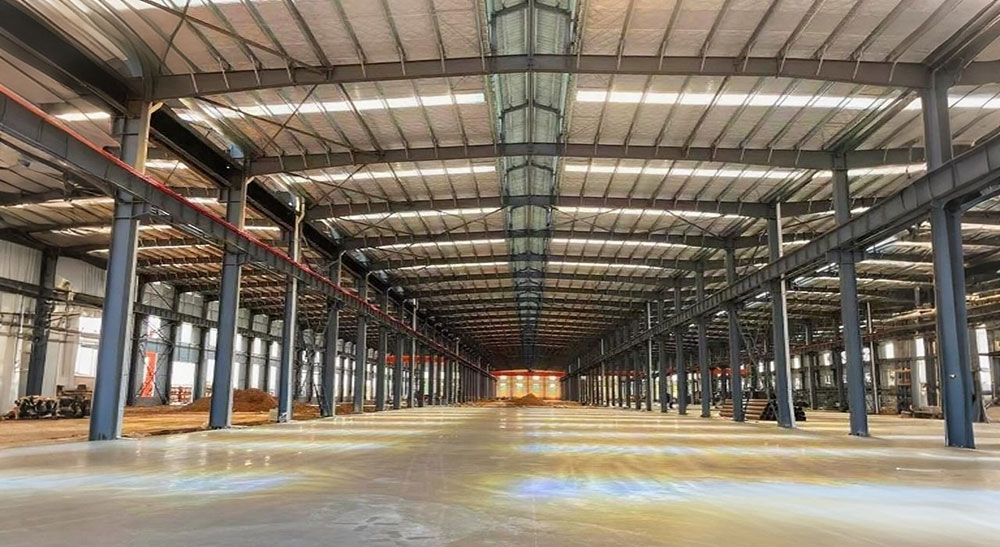

As a committed steel structure building manufacturer, we work with advanced production lines that integrate CNC cutting, automated welding, and full-process quality checks. This ensures every component—from rigid frames to workshop structures—is delivered with consistent accuracy and ready for fast installation on-site.

With international project experience, XTD Steel Structure supports developments across manufacturing, logistics, aviation, and infrastructure by supplying durable, cost-effective systems engineered for long-term performance and environmental resilience.

What We Build

Our manufacturing scope includes industrial workshops, logistic hubs, factory buildings, aviation hangars, agricultural facilities, and large-span commercial structures. Each solution is engineered with material efficiency, safety, and long-term functionality in mind.

As an industry-leading full-process prefab steel building manufacturer, XTD Steel Structure has ploughed deeply into the field of transportation technology facilities for more than 20 years. Relying on the high-performance characteristics of Q355B S355JR A572 SM490A grade high-strength steel, coupled with continuous technological innovation, XTD Steel Structure reconstructs the space of the aviation hubs and provides global customers with a modernized terminal building system that integrates high efficiency and intelligent green building, from the design of the steel structure, processing, manufacturing, construction, to the subsequent maintenance during the use of the building. We create a modernized terminal building system that is highly efficient, intelligent, and green.

In the global exhibition center construction sector, steel structures have emerged as the industry’s preferred solution. As an exhibition center owner, you may currently face the following challenges: traditional concrete buildings typically require 1-2 years of construction time, while pre-booked international convention center might commence as early as next year. You need to strictly control construction budgets while achieving large-span column-free spaces to enhance venue utilization and commercial value. Furthermore, exhibition centers must comply with increasingly stringent green building standards. Steel structure exhibition centers represent the optimal solution to address these pain points. XTD Steel Structure, as a global leader in comprehensive steel construction solutions, delivers modern exhibition center solutions integrating large spans, high flexibility, sustainability, and intelligent features for clients worldwide.

XTD Steel Structure is a prefabricated steel building manufacturer in the field of modular construction, focusing on providing global customers with full-scenario solutions ranging from 30X50 single-story steel factories to multi-story mega plants stretching over several kilometers. With more than 20 years of deep cultivation in the industry, we have successfully delivered thousands of factories and infrastructures, with a cumulative plant construction area of nearly 10 million square meters, setting a benchmark in the field of steel structure construction.

As an innovative leader in the field of global steel structure engineering, XTD Steel Structure gathers the industry’s top R&D team to study the special usage scenarios and functional requirements of gas stations in depth, and customizes high-performance and cost-effective prefabricated steel structure gas station solutions for global customers. The steel structure building adopts a modular design concept, which can split the gas station into several standardized and fast-assembling functional modules, which not only significantly shortens the on-site construction period but also effectively reduces the impact of construction on the surrounding environment.

Our Products

We provide rigid steel frames, modular components, steel trusses, workshop systems, architectural steelwork, and custom assemblies. Every product is designed to optimize structural stability, reduce erection time, and adapt to complex project requirements.

Our Projects

Over the past years, XTD Steel Structure has supplied fabricated systems for port terminals, industrial expansion projects, national logistics parks, airport upgrades, and large-scale factory constructions—delivering reliable results across diverse environments.

Frequently Asked Questions

What defines a reliable steel structure manufacturer?

Reliability depends on engineering capabilities, production technology, inspection standards, and material traceability. A strong steel structure manufacturer ensures consistent performance across every component.

Do you produce buildings for industrial workshops?

Yes. Our experience as a steel structure workshop manufacturer includes single-span and multi-bay workshops, heavy-duty production halls, and facilities requiring overhead cranes or specialized equipment layouts.

Can you manufacture prefabricated steel buildings?

Yes. Our experience as a steel structure workshop manufacturer includes single-span and multi-bay workshops, heavy-duty production halls, and facilities requiring overhead cranes or specialized equipment layouts.

How do you ensure quality in the fabrication process?

Absolutely. As a seasoned prefab steel structure manufacturer, we supply modular systems that reduce on-site labor, speed up installation, and maintain high dimensional accuracy.

Do you export steel structures internationally?

XTD Steel Structure combine automated welding, calibrated CNC machinery, continuous inspection, and certified materials. These standards allow us to operate as a dependable fabricated steel structure manufacturer.

Can your structures withstand harsh weather conditions?

Yes. As a china steel structure manufacturer with global experience, we support overseas clients with engineered components, technical drawings, and structured packaging for easy installation.

What industries benefit most from steel structures?

Our buildings are engineered for region-specific loads, including wind, snow, seismic activity, and temperature fluctuations. Each steel structure building manufacturer solution is tailored accordingly.

Is customization available for unique architectural requirements?

Logistics, manufacturing, aviation, agricultural processing, warehousing, and retail distribution all rely on systems produced by modern steel structure manufacturers.

William L.

John P.

Hassan A. M.

Claire D.

Wei R.

- +86 138 6251 1010

- [email protected]