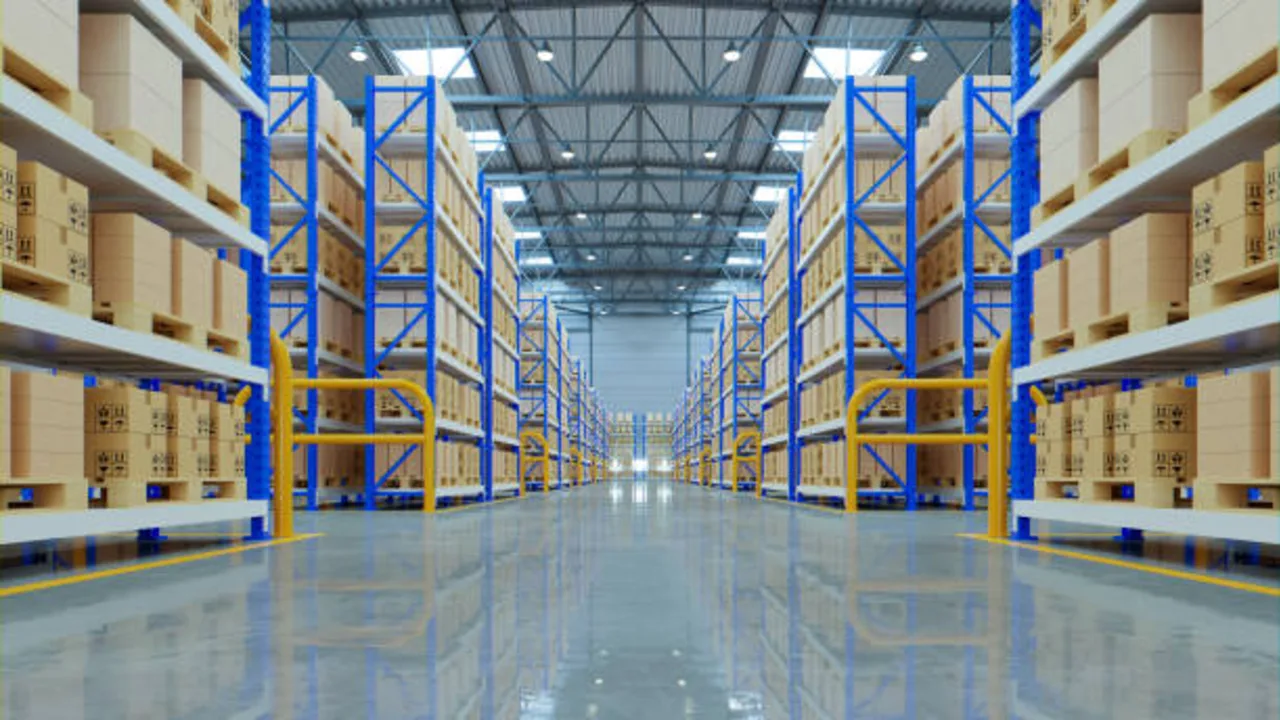

In modern logistics and distribution, warehouse layout efficiency has become a decisive factor in operational performance. Whether you manage a small regional warehouse or a large-scale distribution center, the way your space is organized directly affects productivity, labor cost, inventory accuracy, and delivery speed.

An efficient warehouse layout is not just about fitting more racks into a building. It is about optimizing logistics flow, improving storage density, reducing unnecessary movement, and ensuring that every square meter of space supports faster and safer operations. This article breaks down the top 5 warehouse layout efficiency strategies that work across industries and business sizes.

Why Warehouse Layout Efficiency Matters More Than Ever

For decision-makers, warehouse layout efficiency is no longer an operational detail—it is a direct driver of cost control, service performance, and long-term scalability. As delivery windows shrink, labor costs rise, and SKU volumes expand, inefficient layouts quickly translate into higher operating expenses and missed service targets.

Poor layout planning creates hidden costs: excessive travel time, underutilized storage space, congestion around picking zones, and increased safety risks. These issues compound over time, reducing throughput while increasing reliance on labor and manual intervention.

Improving warehouse layout efficiency enables businesses to:

- Lower labor costs by reducing unnecessary movement and handling

- Improve order accuracy and fulfillment speed without adding headcount

- Increase storage capacity and revenue potential within the same footprint

- Support future growth, automation, and operational flexibility

With the right structural planning and layout strategy, many warehouses achieve 20–40% throughput improvement—often at a fraction of the cost of building expansion. For executives and operations leaders, layout efficiency is one of the fastest ways to unlock measurable ROI inside existing facilities.

1. Design the Layout Around Logistics Flow

One of the most common mistakes in warehouse planning is organizing space around storage first, rather than logistics flow. Efficient warehouses are designed to support the natural movement of goods—from receiving to storage, picking, packing, and outbound shipping.

A flow-oriented layout minimizes backtracking and cross-traffic. Ideally, inbound and outbound zones are clearly separated, and material movement follows a logical, one-directional path. This reduces congestion and improves overall throughput.

When layout planning aligns with logistics flow, businesses experience smoother operations, fewer handling steps, and lower labor fatigue.

2. Increase Storage Density Without Sacrificing Access

Higher storage density is often associated with better space utilization, but over-densifying a warehouse can lead to access issues and slower picking times. The goal is to balance density with accessibility.

Modern layout strategies focus on vertical expansion using mezzanines, multi-level platforms, and optimized racking systems. By building upward instead of outward, warehouses can significantly increase capacity while maintaining clear aisles and safe access.

Many facilities achieve this by integrating elevated platforms and warehouse steel structure systems that support multi-layer storage and operational zones without disrupting ground-level flow.

3. Separate Fast-Moving and Slow-Moving Inventory

Not all inventory deserves equal placement. One of the simplest ways to improve warehouse layout efficiency is zoning products based on movement frequency.

Fast-moving SKUs should be positioned closer to picking and shipping areas, reducing travel distance and handling time. Slow-moving or bulk inventory can be placed in higher or less accessible zones without affecting daily throughput.

This strategy improves picking efficiency, reduces congestion in high-traffic areas, and supports better labor allocation throughout the warehouse.

4. Optimize Aisle Widths and Material Handling Paths

Aisle design plays a critical role in layout efficiency. Aisles that are too wide waste valuable space, while aisles that are too narrow can create safety risks and operational delays.

Efficient warehouses design aisle widths based on the type of equipment used—forklifts, pallet jacks, automated guided vehicles (AGVs), or manual picking carts. Clearly defined material-handling paths prevent conflicts between people and equipment.

According to warehouse optimization studies, adjusting aisle layouts alone can improve picking speed by up to 15%, especially in high-volume operations.

5. Use Flexible Structures That Support Future Changes

Business needs evolve. Seasonal demand shifts, SKU expansion, and automation upgrades all require layout adaptability. Warehouses built with rigid layouts often struggle to scale efficiently.

Flexible structural systems—such as modular platforms and steel-based layouts—allow businesses to reconfigure storage zones, add levels, or adjust workflows without major reconstruction. This flexibility protects long-term layout efficiency and reduces future capital expenditure.

Industry insights from logistics automation experts, including those shared by Element Logic, emphasize that adaptable layouts consistently outperform fixed designs in long-term operational efficiency.

Common Warehouse Layout Mistakes to Avoid

Even well-intentioned warehouse upgrades can fail when layout decisions are made without a holistic view of operations. Below are the most common mistakes that quietly undermine warehouse performance—and how to think about them strategically.

Designing storage before analyzing logistics flow

Many warehouses start by maximizing storage capacity without first mapping how goods move through the facility. This often results in crossing traffic, backtracking, and congestion near picking and shipping zones. A layout should always be designed around logistics flow first, with storage positioned to support smooth inbound, internal, and outbound movement.

Overcrowding racks without considering access and safety

Pushing racks too close together may increase theoretical storage density, but it frequently reduces real-world efficiency. Narrow aisles slow down picking, increase equipment conflicts, and raise safety risks. Overcrowded layouts also limit visibility and make future adjustments costly. True efficiency balances density with access, safety, and operational speed.

Ignoring vertical space potential

Many warehouses focus only on floor area while leaving valuable vertical space unused. This leads to unnecessary expansion or leasing additional facilities. Vertical solutions—such as multi-level platforms or elevated storage zones—can significantly increase capacity without disrupting ground-level operations, making better use of existing assets.

Failing to plan for future expansion or automation

Layouts built only for current demand often become constraints within a few years. SKU growth, automation, and changing order profiles require flexibility. Warehouses that ignore future scalability face expensive retrofits or operational disruption. A layout should anticipate growth, allowing modular expansion and integration of automation when needed.

Conclusion: Building Long-Term Warehouse Layout Efficiency

Warehouse layout efficiency is not a one-time project—it is an ongoing strategy that supports productivity, scalability, and cost control. By focusing on logistics flow, balanced storage density, smart zoning, optimized aisles, and flexible structural systems, warehouses of any size can achieve measurable improvements.

As logistics demands continue to rise, businesses that invest in efficient, adaptable warehouse layouts will gain a clear operational advantage—without necessarily increasing their physical footprint.