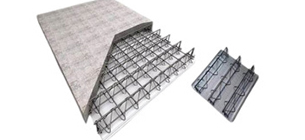

Single Board Maintenance (Floor Board Series) Advantages

|

|

|

|

|

|

|

|

|

The use of single board maintenance systems, particularly in the floor board series, has been gaining popularity across construction and renovation projects. This innovative material is recognized for its superior performance, durability, and practicality in extending the service life of buildings. Unlike traditional construction boards or flooring systems, these panels combine multiple functional benefits such as strength, insulation, protection, and ease of maintenance.

In the following sections, we will explore the key advantages of single board maintenance floor boards, their applications in modern construction, and the unique value they bring to both new projects and renovation efforts.

1. Higher Specific Strength of the Floor Board

One of the most significant advantages of the single board maintenance system is its specific strength, which is higher compared to many conventional building materials. Specific strength refers to the ratio of material strength to its density, meaning the boards provide high load-bearing capacity while remaining relatively lightweight.

- Lightweight yet strong: A lighter material reduces the load on the structural framework of the building, which is especially important in multi-story construction.

- Structural safety: Despite their reduced weight, these boards maintain robust strength, allowing them to withstand pressure, impact, and environmental stresses.

- Reduced foundation costs: Because the boards are lighter, the load transferred to the foundation is smaller, which can lower foundation construction costs without compromising stability.

This balance of lightness and strength ensures that single board maintenance systems can be safely applied in both residential and industrial settings where structural integrity is paramount.

2. Immediate Usability and Low-Maintenance Design

Another major advantage is the ability to use the panels immediately after completion. Once the floor board installation process is finished, the floor board series does not require additional treatments such as curing, polishing, or extended setting times.

- Quick turnover for projects: For commercial spaces, schools, factories, or housing units, time is money. Being able to use a space right after construction provides significant economic benefits.

- No further renovation required: Traditional floors often need post-installation finishing, which adds time and cost. These boards are factory-prepared with protective layers that eliminate the need for refinishing.

- Ease of cleaning and maintenance: The smooth, treated surfaces of the boards resist dust accumulation, water infiltration, and staining, making them very low-maintenance compared to untreated concrete or wood flooring.

This feature makes the single board maintenance system an attractive option for projects that demand speed, cost-efficiency, and minimal disruption.

3. Protection of the Main Structure and Service Life Extension

Beyond their mechanical strength, single board maintenance systems play a crucial role in protecting the primary structure of a building. When used in flooring, roofing, or wall applications, these panels act as an external shield against weather and environmental stressors.

- Moisture protection: The panels significantly reduce the risk of water seepage, which can cause corrosion of steel structures or weakening of concrete.

- Thermal insulation: Properly selected sandwich panels with adequate thickness can control thermal deformation of walls and roofs. By maintaining stable internal conditions, the boards prevent expansion and contraction that could damage the structure.

- Crack prevention: One of the most common problems in conventional construction is the appearance of oblique cracks or octagonal cracks in walls and ceilings. Single board maintenance panels effectively minimize this issue by stabilizing temperature and stress distribution.

- Extended lifespan: With these protective qualities, the main structure can last far beyond its expected life cycle. When combined with periodic coating or surface treatment, the service life of the panels themselves can exceed 30–35 years.

Thus, the use of these panels not only protects the building but also maximizes return on investment for property owners.

4. Energy-Saving Renovation of Old Buildings

Perhaps one of the most remarkable advantages of single board maintenance systems is their role in the energy-saving renovation of older buildings.

Renovation projects often face the challenge of improving energy efficiency without disrupting the lives of occupants. With these panels, both goals can be achieved simultaneously:

- No need for relocation: Since the installation can be carried out externally, residents or office workers do not need to vacate the building during renovation. This makes the process far more convenient compared to conventional retrofitting, which often requires moving tenants.

- Minimal disruption: The installation process is fast and does not generate excessive noise, dust, or debris, ensuring that the indoor life and normal routines of users are not affected.

- Improved energy performance: Sandwich panels offer superior thermal insulation and airtightness, which significantly reduces heating and cooling costs. Over time, this results in major savings for building owners while lowering environmental impact.

- Sustainable urban renewal: By extending the useful life of older buildings and enhancing their energy efficiency, these systems contribute to broader sustainability goals in cities.

This makes single board maintenance systems particularly valuable for public housing upgrades, industrial facility retrofits, and heritage preservation projects where disturbance must be minimized.

5. Practical Applications Across Industries

The advantages of these panels have led to their adoption in a wide range of construction scenarios:

- Residential housing: Used for flooring, wall cladding, and roofing to create energy-efficient and durable homes.

- Industrial facilities: Applied in warehouses, factories, and logistics centers where strong yet low-maintenance materials are crucial.

- Commercial spaces: Popular in malls, supermarkets, and office complexes where appearance, durability, and low maintenance are essential.

- Public infrastructure: Useful in schools, hospitals, and community buildings where renovation must be fast and minimally disruptive.

In all these applications, the single board maintenance system proves its worth by reducing lifecycle costs, improving safety, and supporting sustainable construction practices.

6. Long-Term Economic Benefits

While the initial investment in single board maintenance systems may sometimes be slightly higher than traditional materials, the long-term economic benefits far outweigh the costs.

- Reduced renovation cycles: With their extended lifespan, buildings require fewer major renovations over decades.

- Lower maintenance expenses: Minimal upkeep translates into reduced operating costs for homeowners and facility managers.

- Energy savings: Improved insulation lowers utility bills significantly, particularly in regions with extreme climates.

- Property value enhancement: Buildings equipped with modern, durable, and energy-efficient materials generally have higher resale value.

When considered from a lifecycle perspective, these panels are among the most cost-effective construction solutions available today.

The Single Board Maintenance (Floor Board Series) is more than just a modern construction material—it is a comprehensive solution that integrates strength, durability, energy efficiency, and convenience. Its ability to protect the main structure, prevent cracks, enable quick use after completion, and support energy-saving renovation without displacing occupants makes it a transformative option for both new builds and old building upgrades.

From residential housing to industrial complexes, this system stands as a smart investment for developers, property owners, and governments seeking sustainable, cost-effective, and resilient infrastructure. With proper selection, installation, and periodic coating, these boards can last well over three decades, ensuring that buildings remain safe, functional, and efficient for generations to come.

Application scenarios: medicine, food factories, laboratories, electronics factories

|

|

|

|