When it comes to constructing large buildings like stadiums, airports, factories, and exhibition halls, one of the biggest engineering puzzles is wide-span roof spaces. And that’s precisely where a space truss roof system is an ideal solution. With a combination of strength, efficiency, and architectural flexibility, this structure has revolutionized the way we can approach the construction of wide-span buildings.

In this article, we’ll explore why the space truss roof system is widely preferred for expansive roof spans, its structural advantages, design versatility, and real-world applications.

What Is a Space Truss Roof System?

A space truss roof system is a three-dimensional framework comprised of linked triangles. The triangles disperse weight more effectively, and the structure can cover spaces of broad distance without any support in between. A space truss is different from traditional two-dimensional trusses in that it possesses strength in more than one direction, thus being suitable for contemporary architecture, which requires open space without columns.

Major Advantages of Space Truss Roof Systems

1. Even Load Distribution

Space truss roof systems with the triple structure evenly distribute the load across the frame. This makes them rigidly resistant to deflection, sag, or bend, irrespective of high wind, snow, or seismic load. The system forms a single rigid body, enhancing structural stability.

2. Ideal for Long Spans

Another of its greatest benefits is that it can extend over long distances without the need for interior columns. This makes the truss roof space system extremely well-suited for application in structures such as:

- Stadiums

- Airport terminals

- Convention centers

- Industrial plants

These buildings require open space, which conventional roof systems are generally not able to supply efficiently.

3. Strong and Light

While being strong, space truss systems are very light in weight compared to solid beam or slab construction. This reduces foundation load, construction cost, and installation can be quicker.

4. Design Flexibility

Space trusses can be designed in many shapes — flat, domed, curved, or pyramidal. This provides architects wmaith space to develop aesthetically appealing and functional buildings, with a marriage of form and function.

Common Applications in Modern Buildings

1. Stadiums and Arenas

Stadiums need big open areas with clear sightlines. The space truss roof system is most widely used to span such areas without compromising sightlines in support columns.

2. Airports and Transportation Hubs

Passenger terminals need to have open floor plans to accommodate large crowds and heavy equipment. The structural efficiency of the space truss enables sophisticated, light-filled solutions to be both functional and aesthetically pleasing.

3. Factory and Industrial Buildings

These buildings are provided with open space for equipment, cranes, and workflow in factory buildings with maximum efficiency of operations.

Materials for the Construction of Space Truss Roofs

Space truss roof systems are widely recognized for their efficiency, strength, and versatility in modern architecture and engineering. The choice of materials plays a crucial role in ensuring the performance, safety, and longevity of these structural systems.

Most commonly, steel pipe or hollow structural sections (HSS) are used as the primary materials in space truss roof construction. Steel is favored because of its high strength-to-weight ratio, which allows for longer spans with reduced material use, and its excellent durability, ensuring that the structure can withstand both static and dynamic loads over time. In addition, steel is cost-effective, readily available in standardized forms, and suitable for prefabrication, making it ideal for large-scale roof systems such as stadiums, exhibition halls, and industrial facilities.

For specific applications where environmental conditions are more demanding, alternative materials may be selected. For instance, in corrosive atmospheres such as coastal regions, chemical plants, or marine facilities, protective coatings or corrosion-resistant materials become essential. In such cases, aluminum may be chosen as it offers natural resistance to corrosion while still being lightweight. Similarly, in temporary structures or where reduced weight is critical, advanced composite materials such as fiber-reinforced polymers (FRPs) can be employed. These materials, though more costly, provide unique benefits in terms of weight reduction, resistance to harsh environments, and design flexibility.

The connections within a space truss roof system are equally important in determining structural integrity. Typically, the truss is assembled using precisely engineered joints or nodes, which serve as the link between individual members. These nodes are designed with careful attention to geometry and load transfer to prevent weaknesses in the overall structure. Welding and bolted connections are the most common methods of assembly. Welded joints provide strong, continuous connections, while bolted connections allow for easier installation and disassembly.

In modern construction practice, most nodes and members are prefabricated in controlled factory environments to ensure accuracy, quality, and efficiency. Prefabrication not only improves the precision of connections but also reduces on-site labor and construction time. During assembly, prefabricated components are fitted together with minimal adjustments, ensuring that the roof system performs exactly as designed.

In summary, the materials used in space truss roof systems—whether steel, aluminum, or advanced composites—are carefully selected based on structural demands, environmental conditions, and project requirements. Combined with precision-engineered connections, these materials allow space truss roofs to achieve the perfect balance of strength, durability, and adaptability, making them one of the most effective solutions for modern architectural and industrial projects.

Design and Fabrication Challenges

1. Customization

Space truss design is always project-specific. The engineers make use of expert computer-aided design software for modeling the steel structure and simulating the loads, wind resistance, and temperatures. It is done so that the structure is safe and optimally designed for the purpose it will be put to.

2. Prefabrication

Most of the space truss components are fabricated off-site in controlled factory settings. This prefabrication approach brings multiple benefits: it reduces on-site construction time, limits labor requirements in the field, and cuts down on weather-related delays. Prefabrication also improves quality control, as components are manufactured using automated tools and inspected under consistent standards. Joints, nodes, and members are typically produced to exact specifications and marked for easy assembly, allowing for seamless transportation and on-site installation. In complex projects, mock assembly may also be conducted in the workshop to ensure fitment before final delivery.

3. Maintenance

Although space truss systems are known for their durability and low maintenance, they are not completely intenance-free. Periodic inspections are necessary to assess the condition of joints, coatings, and structural members, especially in outdoor, coastal, or industrial environments where moisture or chemicals are present. Protective coatings such as industrial-grade paint or galvanizing are applied to steel components to prevent corrosion. Over time, these coatings may degrade and require touch-up or reapplication. Inaccessible or elevated areas may demand specialized equipment or scaffolding for inspection and maintenance, which should be factored into long-term operational planning.

Why Select a Space Truss Roof System Over Alternative Roof Systems?

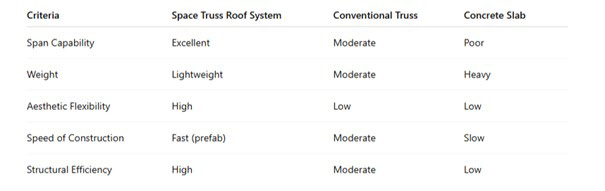

In comparison, space truss systems possess the following advantages:

Real-World Examples and Case Studies

Some of the world-renowned structures utilizing this system are:

- Beijing National Stadium (Bird’s Nest) – Utilizes a complicated steel space truss to achieve its characteristic look.

- King Abdulaziz International Airport, Jeddah – Features a large space truss roof for its terminal building.

- EXPO 2020 Dubai Pavilion – Featured space truss applications of the future with the incorporation of sustainability elements.

Conclusion

The space truss roof system is not just a structural alternative but a smart, economical, and beautiful solution for modern wide-span buildings. It, with its rigidity, flexibility, and reduced material consumption, continues to be the crowning jewel of the skylines of prominent facilities worldwide.

As you lay out a project with extensive open spaces, consider adding a space truss roof system to achieve functional as well as visual potential.