In prefab steel construction, decisions made early do not stay small. Once fabrication begins, even minor design changes can ripple through structural members, connections, schedules, and costs. This is why the concept of a prefab steel design freeze is one of the most critical—and most misunderstood—phases in prefabricated steel projects.

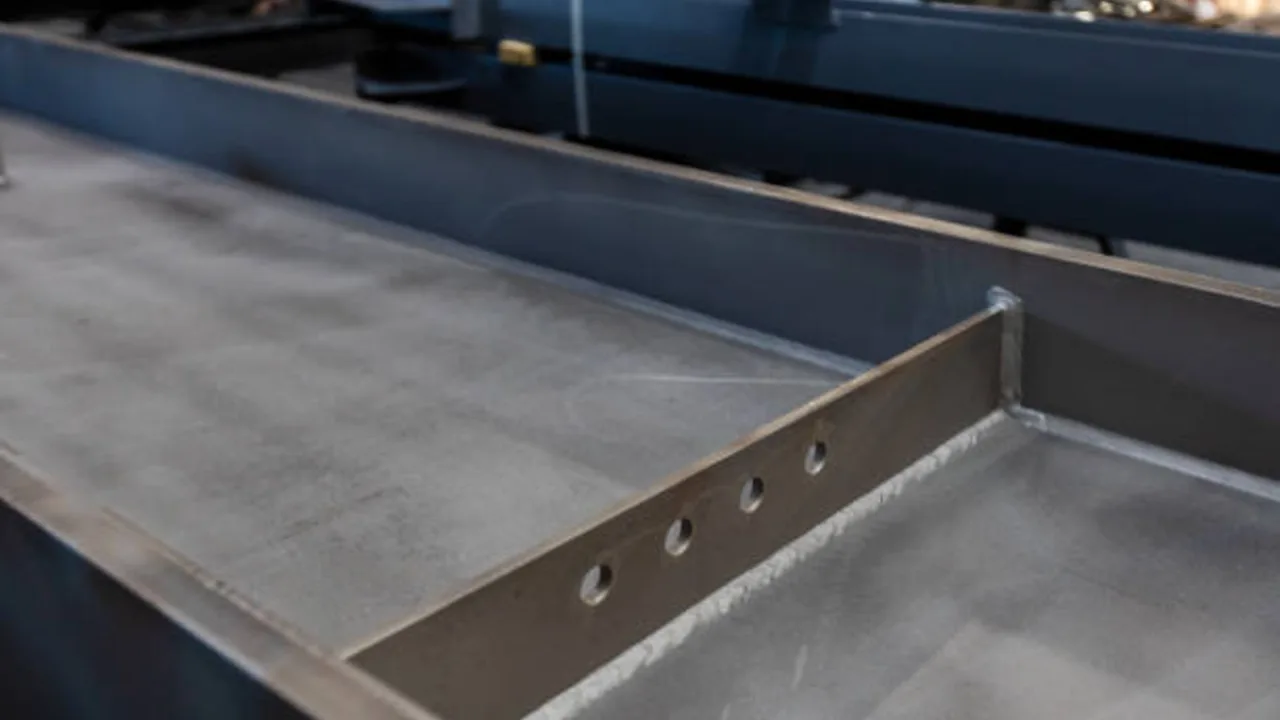

Unlike conventional construction, where adjustments can often be absorbed on site, prefab steel relies on precision manufacturing. Columns, beams, purlins, and connections are fabricated off-site using CNC-controlled processes. When the design is not properly frozen before fabrication, projects risk rework, delays, and cost overruns that can erase the very advantages prefabrication is meant to deliver.

This article explores the real challenges behind prefab steel design freeze, why it must happen early, and how early coordination across disciplines is the only practical way to make design freezing a strategic advantage rather than a project liability.

What Is Design Freeze in Prefab Steel Construction

A design freeze in prefab steel construction is the formal point at which all critical structural, architectural, and coordination decisions are finalized and approved for fabrication. From this moment forward, shop drawings are released, materials are procured, and steel components enter production.

In a prefab steel design freeze, the following are typically locked:

- Structural grid and column spacing

- Primary and secondary steel member sizes

- Connection details and bolt systems

- Roof geometry and load assumptions

- Major openings, penetrations, and equipment zones

This differs sharply from conventional construction, where many details can remain flexible until late stages. In prefab steel, once steel is cut and drilled, flexibility disappears.

Why Prefab Steel Projects Require Early Design Freezing

The core reason prefab steel projects demand early design freeze lies in the fabrication process itself. Steel components are produced with millimeter-level accuracy. Any late change—no matter how small—can invalidate entire batches of fabricated members.

A properly managed prefab steel design freeze allows:

- Efficient CNC fabrication

- Accurate bolt-hole alignment

- Predictable delivery schedules

- Smooth site installation

Without early coordination, design freezing becomes guesswork. Architects, structural engineers, MEP designers, and fabricators must align before fabrication begins, not after problems appear on site.

Key Design Elements That Must Be Frozen Early

Structural Grid and Column Spacing

The structural grid defines everything in a prefab steel building. Column spacing affects beam spans, roof systems, cladding modules, crane layouts, and future expansion options. Changing grid dimensions after a prefab steel design freeze often requires redesigning most of the steel frame.

Connection Details and Bolt Systems

Connections are among the most expensive elements to revise. Base plates, end plates, anchor bolts, and splice details are fabricated precisely. Late changes can make prefabricated components unusable, leading to scrap and re-fabrication.

Roof System and Load Assumptions

Roof geometry, slope, and load assumptions must be fixed before fabrication. Snow load revisions, added equipment, or misunderstood wind criteria frequently cause conflicts when discovered too late. A disciplined prefab steel design freeze prevents these risks.

MEP Penetrations and Equipment Layout

In prefab steel construction, MEP openings cannot be treated as “field adjustments.” Duct routes, cable trays, and equipment platforms must be coordinated early. This is where early coordination between structural and MEP teams becomes non-negotiable.

Common Design Freeze Challenges in Prefab Steel Projects

Despite best intentions, many prefab steel projects struggle to achieve a clean and stable design freeze. The core issue is not technical capability, but misalignment in timing, responsibility, and decision-making across stakeholders. In a prefabricated environment, design uncertainty does not remain isolated—it directly affects fabrication accuracy, production sequencing, and site execution.

One of the most common challenges comes from clients delaying final decisions. In prefab steel construction, late confirmation of building dimensions, equipment layouts, or future expansion plans can prevent engineers from locking critical parameters. What may appear to be a “small decision still under review” at the client level often translates into unresolved grids, connection assumptions, or load criteria at the engineering level. This uncertainty weakens the foundation of a proper prefab steel design freeze.

Architectural changes after structural approval are another frequent source of disruption. Adjustments to façade systems, roof geometry, mezzanine layouts, or internal clearances can invalidate previously approved structural calculations. Because steel members are dimensioned precisely for their loads and spans, even minor architectural revisions can force redesign of beams, columns, or bracing systems—especially if fabrication has already started.

Late involvement of MEP consultants is equally damaging. Mechanical, electrical, and plumbing systems require predefined routes, penetrations, and equipment zones that must be coordinated with the steel structure. When MEP design is introduced after structural drawings are finalized, conflicts emerge that cannot be resolved without cutting, reinforcing, or modifying prefabricated members. This is one of the clearest indicators of insufficient early coordination in prefab steel projects.

Regulatory uncertainty also plays a role. Local code interpretations may evolve during the design phase, particularly in regions with unclear enforcement practices or project-specific approvals. Changes in fire rating requirements, seismic coefficients, or wind load criteria can force last-minute structural revisions, destabilizing an otherwise complete design freeze.

Finally, differences in detailing standards between designers and fabricators often surface too late. Engineers may design connections based on theoretical models, while fabricators rely on standardized shop practices. If these approaches are not aligned before fabrication release, connection details become a point of friction, leading to redesign, RFIs, and production delays.

Individually, these challenges may seem manageable. Collectively, they erode the reliability of the prefab steel design freeze, increasing cost, schedule risk, and coordination complexity. Successful projects address these issues proactively by aligning decisions, responsibilities, and technical standards well before fabrication begins.

How Late Design Changes Impact Prefab Steel Fabrication

Late design changes are not neutral—they actively damage project performance. Once fabrication starts, revisions trigger:

- Steel material waste

- Re-engineering costs

- Fabrication delays

- Disrupted logistics and site sequencing

- Loss of prefab efficiency advantages

In extreme cases, projects revert to on-site modifications, defeating the purpose of prefabrication entirely.

Role of Early Coordination in Preventing Design Freeze Issues

Early coordination is the single most effective way to control design freeze risks. This means aligning all stakeholders before fabrication release:

- Owner and operator

- Architectural team

- Structural engineer

- Steel fabricator

- MEP consultants

Coordination workshops, BIM clash detection, and staged approvals ensure that the prefab steel design freeze is informed, intentional, and defensible.

Design Freeze vs Flexibility: Finding the Right Balance

Design freeze does not mean eliminating all flexibility. Smart prefab projects distinguish between elements that must be frozen and those that can remain adaptable.

Effective strategies include:

- Allowing reserve capacity in structural members

- Designing future-ready openings

- Planning expansion zones within the original grid

This balance preserves long-term adaptability without compromising fabrication certainty.

Best Practices to Manage Prefab Steel Design Freeze

Successful projects treat design freeze as a managed process, not a deadline panic. Best practices include:

- Clear design-freeze checklists

- Formal sign-off procedures

- Stage-based approval milestones

- Realistic buffers for client decisions

- Direct communication with fabricators

Case Examples: Design Freeze Problems in Real Prefab Steel Projects

Warehouse Project with Late MEP Changes

In this project, duct routing was revised after steel fabrication had begun. The result was field cutting of beams, added reinforcement, and delayed installation. The lack of early coordination directly compromised the prefab steel design freeze.

Industrial Building with Revised Roof Load

A late change in roof equipment loading forced redesign of trusses already fabricated. Several members had to be scrapped, increasing cost and extending the schedule by weeks.

How Design Freeze Affects Cost, Schedule, and Risk

A poorly managed prefab steel design freeze increases:

- Construction costs

- Schedule uncertainty

- Contractual disputes

- Site safety risks

Conversely, a disciplined freeze supported by early coordination improves predictability and reduces overall project risk.

When to Lock the Design in a Prefab Steel Project

The ideal moment to lock the design is after:

- Concept and schematic design approval

- Full structural and MEP coordination

- Fabricator detailing review

Warning signs that a project is not ready include unresolved equipment layouts, unclear loads, or incomplete authority approvals.

Conclusion: Design Freeze as a Strategic Decision

A prefab steel design freeze is not an obstacle—it is a strategic control point. When supported by early coordination, it protects budgets, stabilizes schedules, and unlocks the full efficiency of prefabrication.

Projects that respect the discipline of design freezing consistently deliver better-performing structures, especially in complex systems such as a prefabricated steel building structure.