Engineering Supporting Products

|

|

|

|

|

|

In modern construction and industrial development, the role of Engineering Supporting Products has become increasingly critical. These essential materials not only provide structural strength and stability but also ensure that large-scale projects are completed efficiently, safely, and in compliance with international standards. Whether it is a high-rise building, an industrial warehouse, or an infrastructure project such as bridges or factories, the integration of C-type steel, Z-type steel, angle steel, channel steel, and square tube plays a decisive role in shaping the overall success of construction.

At XTD Steel Structure, one of the leading providers in the field, Engineering Supporting Products are designed, manufactured, and supplied with precision, ensuring long-term durability, performance, and cost-effectiveness. This comprehensive description will explore the importance of these products, their applications, unique features, and why they remain a trusted solution for industries worldwide.

The Importance of Engineering Supporting Products

Engineering Supporting Products serve as the backbone of many structural systems. They act as key components that distribute loads, resist deformation, and enhance the longevity of entire projects. For example, in steel structures, beams and columns require proper support and reinforcement to handle stress factors such as wind load, seismic activity, or heavy machinery.

Without reliable Engineering Supporting Products, a building or industrial project risks premature wear, structural failures, or high maintenance costs. Therefore, construction companies, developers, and engineers rely on these products to guarantee safety and compliance with engineering codes.

XTD Steel Structure recognizes these demands and ensures its product range meets strict quality benchmarks. Every piece of C-type steel, Z-type steel, angle steel, channel steel, or square tube is manufactured using advanced technologies to deliver superior mechanical performance.

Types of Engineering Supporting Products

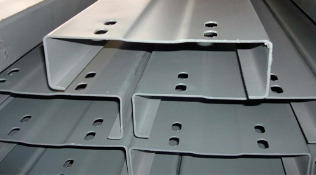

1. C-Type Steel

C-type steel, also known as C-shaped channel, is widely used for purlins, wall beams, and structural bracing. With its excellent strength-to-weight ratio, it provides reliable support without adding unnecessary weight to the structure. C-type steel is versatile and easy to assemble, making it a popular choice for warehouses, workshops, and commercial facilities.

2. Z-Type Steel

Z-type steel is designed primarily for roof purlins and wall girt systems. Its unique Z-shaped profile allows overlapping and stronger connections, ensuring enhanced rigidity in wide-span structures. Z-type steel is especially valued in projects requiring large-scale roofing systems, as it can withstand heavy loads and environmental challenges.

3. Angle Steel

Angle steel, often referred to as L-angle or angle bar, is one of the most commonly used Engineering Supporting Products. Its simple yet effective design makes it perfect for frameworks, reinforcement, and bracing systems. Angle steel is also a cost-effective option, providing both strength and stability in construction, bridges, and equipment manufacturing.

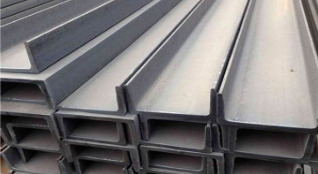

4. Channel Steel

Channel steel is another essential product, often used for structural support in both construction and industrial equipment. Its U-shaped cross-section provides durability and stability in beams, columns, and frameworks. Channel steel is widely applied in shipbuilding, automotive frames, and construction projects requiring high rigidity.

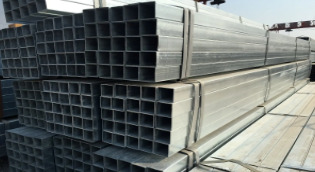

5. Square Tube

Square tubes are hollow steel sections that combine strength with lightweight properties. They are widely used in columns, mechanical structures, handrails, and furniture. Their uniform geometry ensures even load distribution, making them suitable for a variety of architectural and engineering applications. Square tubes also offer aesthetic appeal in modern building designs.

Applications of Engineering Supporting Products

The applications of Engineering Supporting Products span across multiple industries and sectors:

- Construction: High-rise buildings, residential complexes, warehouses, and commercial facilities depend on these products for their frameworks, roofs, and support systems.

- Industrial Manufacturing: From heavy machinery to factory setups, these products provide the necessary stability for safe operation.

- Infrastructure Projects: Bridges, tunnels, and railways utilize angle steel, channel steel, and tubes to ensure reliable support under heavy stress conditions.

- Energy Projects: Power plants, renewable energy structures, and pipelines often incorporate C-type and Z-type steels for both structural and safety reasons.

- Interior & Architectural Use: Square tubes and channel steel are also applied in furniture, partition systems, and modern aesthetic designs.

Advantages of Engineering Supporting Products

Choosing Engineering Supporting Products provides numerous benefits for engineers, contractors, and investors:

- High Strength and Durability: Designed to withstand heavy loads and environmental challenges, ensuring long service life.

- Versatility: Suitable for a wide range of applications, from small frameworks to large industrial complexes.

- Cost-Effectiveness: By minimizing the need for frequent repairs and replacements, these products reduce overall project costs.

- Ease of Construction: Their standardized profiles and dimensions allow quick assembly, reducing construction time.

- Compliance with Safety Standards: Manufactured under strict quality control, ensuring compliance with international engineering codes.

Why Choose XTD Steel Structure for Engineering Supporting Products?

XTD Steel Structure has built its reputation on reliability, innovation, and excellence in the supply of Engineering Supporting Products. Clients from diverse industries trust the company for several reasons:

- Advanced Manufacturing: Using state-of-the-art technology to ensure precise dimensions, superior strength, and consistent quality.

- Custom Solutions: Providing tailored designs and specifications to meet unique project requirements.

- Global Standards: Adhering to ISO, ASTM, and other international quality certifications.

- Customer Support: Offering technical consultation and after-sales services to support clients through every stage of their project.

- Sustainability Commitment: Focusing on eco-friendly manufacturing practices and recyclable steel products.

The Future of Engineering Supporting Products

As industries continue to grow and modernize, the demand for innovative and reliable Engineering Supporting Products will increase. With new construction techniques, digital modeling, and sustainable building practices, these products will evolve to meet the challenges of the future. XTD Steel Structure is at the forefront of this evolution, investing in research and development to deliver advanced solutions that support next-generation construction.

From prefabricated steel structures to green building designs, the role of Engineering Supporting Products will remain central in shaping efficient, sustainable, and safe infrastructures worldwide.

In summary, Engineering Supporting Products such as C-type steel, Z-type steel, angle steel, channel steel, and square tubes form the foundation of modern construction and industrial development. Their unmatched strength, durability, and versatility make them indispensable for a wide range of applications. With XTD Steel Structure’s commitment to quality and innovation, clients are guaranteed products that meet the highest standards of engineering excellence.

For contractors, developers, and industrial leaders, choosing the right Engineering Supporting Products is not just about buying materials—it is about investing in safety, efficiency, and the long-term success of their projects.