In modern industrial construction and manufacturing, steel fabrication plays a critical role in determining a structure’s performance, durability, and long-term value. One of the most common questions engineers, project owners, and procurement teams face is how to choose between light vs heavy steel fabrication. While both approaches rely on steel as a core material, their applications, design requirements, and structural behavior differ significantly.

This guide explains the key differences between light and heavy steel fabrication, focusing on plate thickness, load capacity, fabrication processes, and real-world use cases to help you make an informed decision.

Understanding Light Steel Fabrication

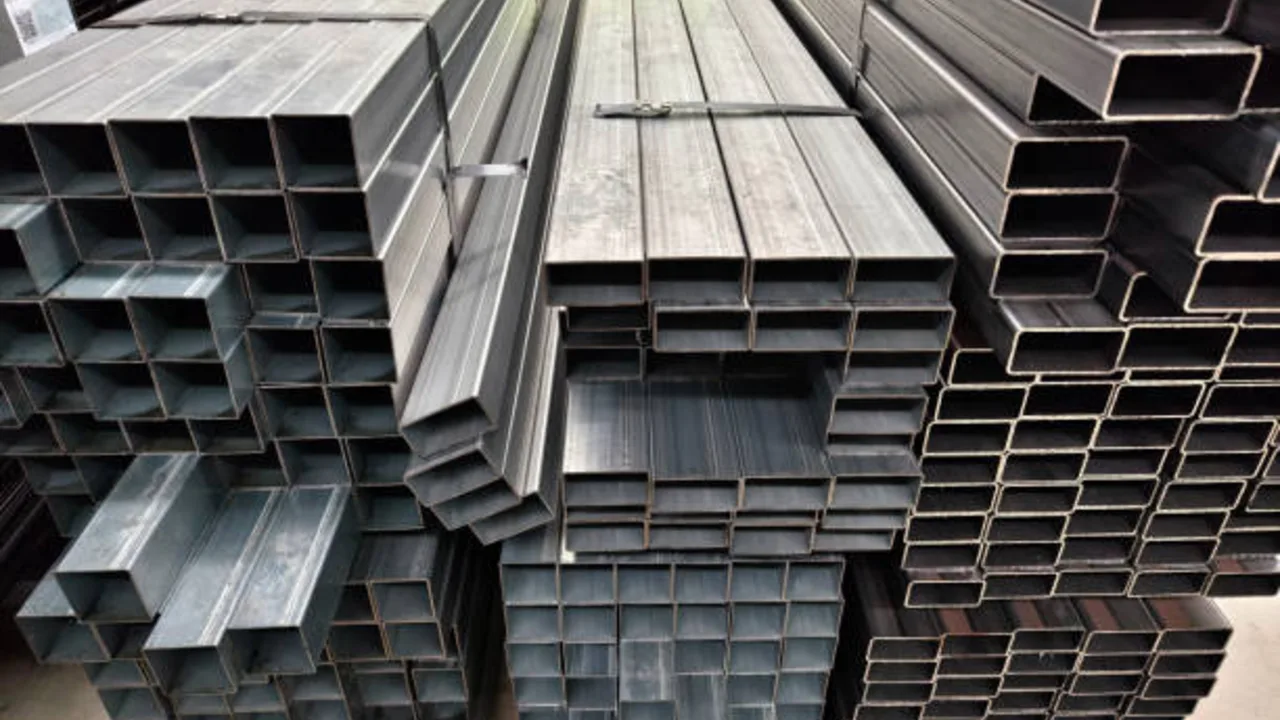

Light steel fabrication typically involves thinner steel sections that are cold-formed or lightly welded into structural components. These systems are widely used in projects where weight efficiency, speed of installation, and cost control are priorities.

Typical Characteristics of Light Steel Fabrication

- Thinner plate thickness, usually under 6–8 mm

- Lower structural load capacity compared to heavy steel

- Cold-formed sections such as C-channels and Z-purlins

- Faster production and easier transportation

- Ideal for modular and prefabricated systems

Light steel systems are commonly applied in low-rise buildings, warehouses, light industrial workshops, and secondary structural elements where extreme loads are not required.

Understanding Heavy Steel Fabrication

Heavy steel fabrication involves thick steel plates, large cross-section beams, and high-strength welded assemblies designed to support extreme loads and long spans. This approach is essential in heavy industrial environments where structural failure is not an option.

Key Features of Heavy Steel Fabrication

- Plate thickness often exceeding 10–20 mm

- High load capacity for static and dynamic loads

- Hot-rolled H-beams, box columns, and plate girders

- Complex welding, machining, and quality control processes

- Designed for long service life under harsh conditions

Heavy steel systems are widely used in power plants, steel platforms, bridges, shipyards, mining facilities, and large-scale industrial structures that require superior strength and rigidity.

Light vs Heavy Steel Fabrication: Key Differences

| Comparison Factor | Light Steel Fabrication | Heavy Steel Fabrication |

|---|---|---|

| Plate Thickness | Thin plates and sections | Thick plates and heavy sections |

| Load Capacity | Low to moderate loads | High and extreme loads |

| Fabrication Process | Cold forming, light welding | Heavy welding, machining, heat treatment |

| Typical Applications | Warehouses, sheds, light workshops | Industrial platforms, plants, bridges |

| Structural Lifespan | Moderate | Long-term, heavy-duty use |

How Plate Thickness Impacts Structural Performance

Plate thickness is one of the most critical engineering variables when comparing light vs heavy steel fabrication, because it directly influences how a structure behaves under load, over time, and in real operating conditions. Thickness affects not only strength, but also stiffness, fatigue resistance, vibration control, and long-term reliability.

Thicker steel plates significantly increase a structure’s moment of inertia, which improves resistance to bending and deflection under heavy static loads. This is especially important in environments where steel structures must support heavy machinery, storage systems, or moving equipment such as cranes and conveyors. In heavy steel fabrication, thick plates help distribute concentrated loads more evenly across beams and columns, reducing localized stress and lowering the risk of cracking or structural failure.

From a fatigue perspective, thicker plates perform better under cyclic and dynamic loading. Industrial facilities often experience repeated stress from machine operation, vibration, thermal expansion, and impact forces. Thicker plates can absorb and dissipate these stresses more effectively, delaying fatigue crack initiation and extending the service life of the structure. This is why heavy-duty platforms, industrial floors, and load-bearing frames almost always rely on heavier plate sections.

In contrast, thinner plates are commonly used in light steel fabrication to minimize material usage, reduce overall weight, and lower project costs. While this approach is efficient for light-duty applications, thinner plates are more sensitive to buckling, vibration, and deflection. If not properly engineered, they can lead to noticeable floor bounce, excessive movement, or long-term deformation under sustained loads.

Thinner steel sections also require more precise structural design. Engineers must carefully control span lengths, connection details, and load distribution to ensure performance remains within acceptable limits. Even small miscalculations in plate thickness can result in amplified vibration issues, particularly in elevated platforms or mezzanine systems where human comfort and equipment stability are concerns.

Choosing the wrong plate thickness has serious consequences. Under-designed plates may experience premature structural fatigue, excessive deflection, or permanent deformation, all of which increase maintenance costs and safety risks. Over-designed plates, on the other hand, can unnecessarily increase material costs and fabrication complexity. The optimal solution lies in matching plate thickness to actual load requirements, operating conditions, and lifecycle expectations of the structure.

In practice, this is the key reason why heavy industrial facilities favor heavy steel fabrication, while light commercial or modular buildings often adopt lighter steel systems. Plate thickness is not just a material choice — it is a fundamental decision that defines the structural performance, safety margin, and long-term value of the entire steel structure.

Load Capacity and Safety Considerations

Load capacity directly determines whether a structure can safely support machinery, storage systems, or operational platforms. Heavy steel fabrication is designed to handle concentrated loads, dynamic forces, and long spans without compromising safety.

For projects involving cranes, heavy machinery, or elevated platforms, opting for heavy steel structure fabrication ensures compliance with engineering standards and reduces long-term risk.

Cost, Installation, and Lifecycle Comparison

While light steel fabrication generally offers lower upfront costs and faster installation, heavy steel fabrication delivers superior lifecycle value for demanding industrial environments. Heavy structures require higher initial investment but benefit from reduced maintenance, longer service life, and greater adaptability for future upgrades.

The right choice depends on balancing initial budget constraints with long-term operational requirements.

Choosing the Right Fabrication Method for Your Project

When deciding between light and heavy steel fabrication, consider the following factors:

- Required load capacity and safety margins

- Plate thickness and structural rigidity

- Environmental conditions and corrosion exposure

- Future expansion or modification needs

- Compliance with local and international standards

Industry resources such as guidance from highlight that selecting the correct fabrication approach early in the design phase can significantly reduce project risk and cost overruns.

Conclusion

Understanding the differences between light vs heavy steel fabrication is essential for achieving structural safety, efficiency, and long-term performance. Light steel systems excel in speed and cost efficiency, while heavy steel fabrication provides unmatched strength, durability, and load-bearing capability for demanding industrial applications.

By evaluating plate thickness, load capacity, and project requirements, decision-makers can select the fabrication method that best aligns with both technical and business objectives.