In modern manufacturing, efficiency is no longer driven by machinery alone. One of the most overlooked but high-impact factors is steel factory layout optimization. The way a factory is physically arranged determines how materials move, how workers interact with equipment, and how smoothly production flows from one stage to the next.

A well-planned steel factory layout does more than organize space—it reduces waste, shortens production cycles, improves safety, and supports future expansion. For factories operating under tight margins and growing demand, layout optimization becomes a strategic advantage rather than a one-time design decision.

What Is Steel Factory Layout Optimization?

Steel factory layout optimization refers to the systematic planning and arrangement of production areas, equipment, storage zones, and circulation paths within a steel-structured industrial building. The objective is to create a layout that supports efficient production flow, minimizes unnecessary movement, and aligns physical space with operational priorities.

Unlike conventional factory buildings, steel structure factories offer greater flexibility. Long spans, column-free zones, and modular framing systems allow layouts to be designed around workflow rather than forcing workflow to adapt to structural limitations.

Why Layout Matters in Steel Structure Factories

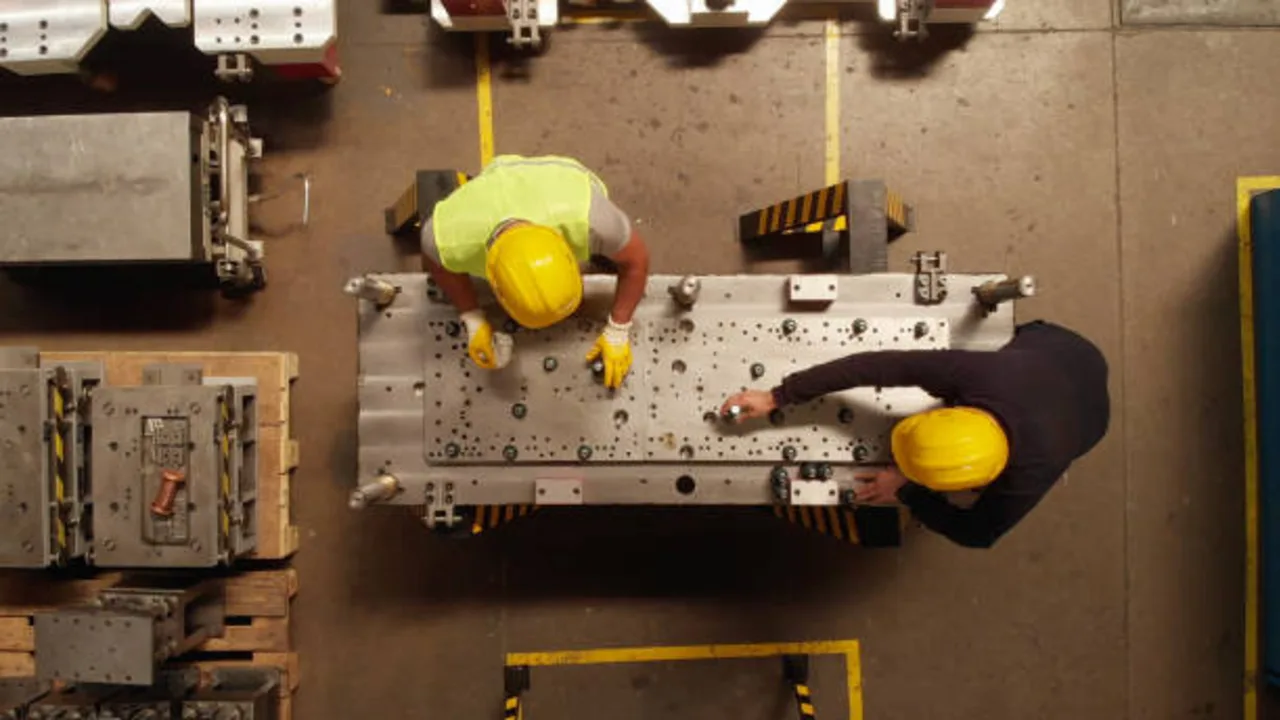

In steel structure factories, layout decisions are not cosmetic choices — they directly shape how efficiently the operation runs day after day. From material intake to final dispatch, the physical arrangement of spaces determines whether production flows smoothly or stalls under avoidable friction. Unlike equipment upgrades or staffing changes, layout inefficiencies are structural; once embedded, they quietly drain productivity over years.

One of the most common consequences of poor layout planning is excessive material handling. When raw materials, semi-finished components, and finished goods must travel long distances or double back across the factory floor, labor hours increase and material-handling equipment is overused. Forklifts, cranes, and conveyors end up compensating for bad layout decisions, driving up maintenance costs and increasing the likelihood of damage or downtime.

Another critical issue is crossing workflows. When inbound materials, production lines, maintenance access, and outbound logistics intersect in uncontrolled ways, bottlenecks become unavoidable. These crossings slow down production, increase waiting time between processes, and introduce serious safety risks. In steel factories where heavy loads and moving equipment are the norm, poorly separated workflows can quickly escalate from inefficiency to accident risk.

Unclear zoning further compounds operational problems. Without clearly defined areas for production, storage, inspection, and logistics, factories experience congestion and confusion. Workers spend unnecessary time navigating shared spaces, supervisors struggle to enforce process discipline, and inventory control becomes harder to manage. Over time, this lack of spatial clarity reduces consistency and makes process optimization difficult.

Perhaps most damaging in the long term is a rigid layout that limits scalability. Steel factories are rarely static — production volumes change, new machinery is added, and processes evolve. Layouts that are tightly constrained by column placement, narrow aisles, or fixed process routes make future upgrades expensive and disruptive. Instead of adapting smoothly, expansions require shutdowns, rework, or even partial demolition.

Optimizing the layout from the beginning addresses these issues at their root. By aligning steel structure design with production flow, zoning logic, and expansion planning, factories operate with fewer disruptions and greater predictability. This becomes especially critical in high-throughput or multi-shift environments, where even small inefficiencies multiply rapidly across shifts, volumes, and labor costs.

Production Flow as the Core Design Principle

At the heart of layout optimization lies production flow. Every factory has a sequence: raw materials enter, processing occurs, assembly follows, and finished goods exit. The physical layout should mirror this sequence as closely as possible.

Linear vs. Process-Oriented Flow

Steel factories often benefit from linear or semi-linear flow patterns:

- Linear flow: Ideal for standardized, high-volume production

- U-shaped flow: Supports compact operations with shared labor

- Process-oriented flow: Suitable for complex or custom fabrication

Steel structure buildings support all three by allowing wide spans and flexible internal zoning without excessive columns or load-bearing walls.

Zoning Strategy in Steel Factory Layouts

Effective zoning separates functions while maintaining logical connectivity. Each zone serves a specific purpose but remains aligned with the overall production flow.

Common Functional Zones

- Raw material receiving and inspection

- Primary processing or fabrication area

- Assembly and finishing zones

- Quality control and testing

- Packaging and outbound logistics

Steel structures make zoning clearer and more adaptable. Mezzanines, platforms, and elevated walkways can further separate people, materials, and machines without increasing footprint.

How Steel Structure Design Enhances Layout Efficiency

The structural characteristics of steel factories play a critical role in layout optimization:

- Large clear spans allow uninterrupted production lines

- High load capacity supports heavy machinery placement

- Vertical expansion enables multi-level production or storage

- Modular framing allows future reconfiguration

When combined with smart layout planning, these features transform the factory building into an operational asset rather than a constraint.

Reducing Material Handling and Travel Distance

One of the primary goals of steel factory layout optimization is minimizing unnecessary movement. Every meter traveled by materials or workers adds time, cost, and risk.

Optimized layouts reduce:

- Forklift travel distances

- Manual handling steps

- Cross-traffic between departments

Shorter paths lead to faster throughput, lower energy use, and safer working conditions—especially in heavy industrial environments.

Safety and Compliance Through Better Layout Planning

Safety is not only a policy issue—it is a layout issue. Poorly planned factories often mix pedestrian routes with machinery or logistics traffic.

Steel factory layouts can integrate:

- Dedicated walkways and escape routes

- Clear separation between people and machines

- Overhead platforms for maintenance access

- Load-zoned floors based on equipment weight

These design choices reduce accident risks while supporting regulatory compliance.

Scalability and Future Expansion

Factories rarely remain static. Production volumes increase, new machinery is introduced, and processes evolve. A rigid layout becomes obsolete quickly.

Steel structure factories support scalable layouts by:

- Allowing bay-by-bay expansion

- Supporting modular production lines

- Enabling vertical additions without shutdown

This flexibility ensures long-term value and protects capital investment.

Integrating Layout Optimization with Building Design

True optimization happens when layout planning and building design are developed together. Treating the factory structure and workflow as separate decisions often leads to compromises.

A well-designed factory steel structure aligns column spacing, roof height, floor loading, and circulation routes with actual production needs—creating a seamless connection between structure and operation.

Conclusion: Layout as a Strategic Advantage

Steel factory layout optimization is not just about arranging machines—it is about designing efficiency into the DNA of the factory. By prioritizing production flow, clear zoning, and future scalability, steel structure factories can achieve higher productivity, lower operating costs, and improved safety.

For manufacturers seeking long-term competitiveness, investing in layout optimization at the planning stage delivers returns far beyond the construction phase—turning the factory itself into a performance-driven system.