Before a Steel Structure Warehouse Guyana project reaches its destination, every step—from engineering decisions to final packaging—must be executed with precision. Overseas industrial construction is unforgiving. Once the materials arrive on site, there is little room for error, especially when the project is thousands of kilometers away from the manufacturing base.

This is why export-ready steel structure projects require more than just fabrication capacity. They demand experience, environmental understanding, and strict quality control.

One of our latest projects, a Steel Structure Warehouse Guyana order currently in the final packaging stage, demonstrates how proper material selection, international welding standards, and controlled manufacturing processes come together to support long-term performance in a challenging environment. The structure will be shipped to Guyana shortly, fully prepared for installation upon arrival.

At XTD Steel Structure, projects like this reflect a consistent delivery philosophy: precision in manufacturing, protection during transport, and performance on site.

Understanding the Local Environment: Why Steel Structure Warehouse Guyana Requires Special Planning

Guyana’s climate plays a critical role in how industrial buildings must be designed and manufactured. Located on the northern coast of South America, Guyana experiences:

- High annual humidity

- Heavy rainfall and prolonged moisture exposure

- Warm temperatures that accelerate corrosion

For any Steel Structure Warehouse Guyana project, these conditions directly influence steel durability, joint performance, and long-term maintenance requirements. Structures that are not properly designed for such environments can suffer early corrosion, weakened connections, and increased lifecycle costs.

Instead of applying a generic steel solution, our engineering team evaluated the environmental demands of Guyana before finalizing materials and fabrication methods. The result is a warehouse structure specifically prepared to withstand humidity and corrosion risks common in the region.

Material Selection for Steel Structure Warehouse Guyana Projects

Material choice is one of the most important decisions in any Steel Structure Warehouse Guyana project. In high-humidity environments, untreated or improperly protected steel can quickly become a liability.

Why Galvanized Steel Was Selected

For this warehouse, galvanized steel was chosen as the primary structural material due to its proven performance in humid and coastal regions.

Key advantages include:

- Superior corrosion resistance through zinc coating protection

- Extended service life compared to untreated steel

- Lower long-term maintenance costs

- Consistent protection across beams, columns, and secondary members

In a Steel Structure Warehouse Guyana, galvanized steel significantly reduces the risk of rust development during both transportation and long-term operation. This ensures that the structure maintains its integrity from installation through decades of use.

Welding Standards: Ensuring Structural Reliability for Steel Structure Warehouse Guyana

Beyond material selection, welding quality plays a decisive role in structural performance. For export projects like a Steel Structure Warehouse Guyana, welding must meet internationally recognized standards to ensure safety and acceptance.

All welding for this project followed American welding standards commonly applied in global industrial construction. These standards focus on:

- Proper weld penetration and fusion

- Uniform, clean weld appearance

- Structural consistency across repeated components

- Reduced risk of cracking or fatigue under load

Why This Matters for Overseas Projects

For international clients and EPC contractors, welding quality is often inspected against familiar standards. By following American welding practices, the Steel Structure Warehouse Guyana project aligns with expectations for strength, safety, and documentation.

This approach minimizes disputes during inspection and ensures smooth acceptance during on-site installation.

Factory-Controlled Manufacturing for Steel Structure Warehouse Guyana

All components of the Steel Structure Warehouse Guyana were fabricated in a controlled factory environment. This method offers a significant advantage over on-site fabrication, especially for overseas projects.

Benefits of Factory Fabrication

- High dimensional accuracy through CNC cutting and controlled welding

- Repeatable quality across all structural members

- Pre-installation verification of connections and alignment

- Reduced on-site labor requirements

Producing the warehouse structure in the factory allows potential issues to be identified early. This significantly reduces installation risks and prevents costly delays once the materials arrive in Guyana.

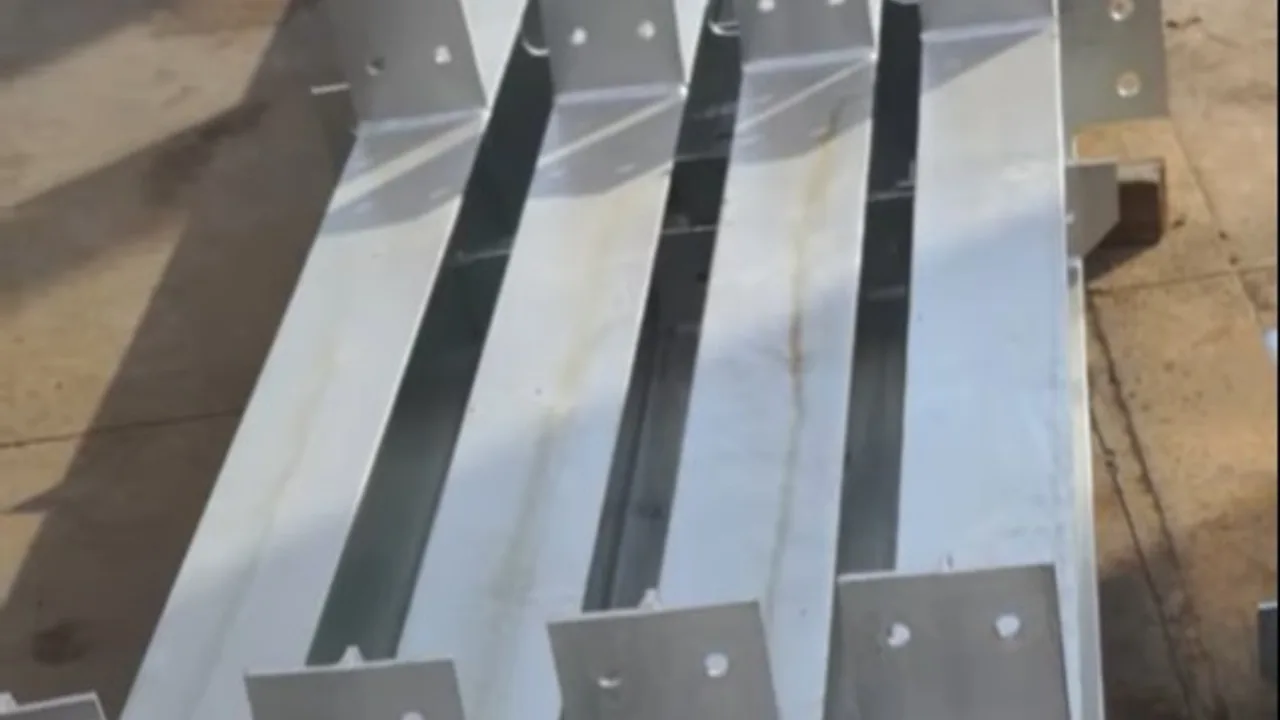

Final Packaging Stage: Protecting the Steel Structure Warehouse Guyana During Transport

The project has now entered the final packaging stage, a critical phase in any Steel Structure Warehouse Guyana delivery. Long-distance sea transport exposes steel components to movement, moisture, and handling risks.

Packaging Considerations for Overseas Shipment

For this project, packaging was designed to:

- Protect galvanized surfaces from damage

- Secure structural members to prevent deformation

- Organize components according to installation sequence

- Ensure clear identification for unloading and erection

Proper packaging ensures that the Steel Structure Warehouse Guyana components arrive on site in optimal condition, ready for immediate installation without rework.

Export Logistics: From Factory to Guyana

Shipping a Steel Structure Warehouse Guyana project across continents requires careful coordination between manufacturing, logistics, and documentation teams.

Key logistics considerations include:

- Shipment scheduling aligned with construction timelines

- Accurate packing lists and component labeling

- Export documentation prepared for smooth customs clearance

- Coordination with experienced freight partners

This structured logistics approach ensures that the warehouse structure is delivered on schedule, minimizing downtime and uncertainty for the project owner.

Why Steel Structure Warehouse Guyana Projects Favor Steel Construction

Steel structures have become the preferred solution for industrial warehouses worldwide, and Steel Structure Warehouse Guyana projects are no exception.

Advantages of Steel Structure Warehouses

- Faster construction timelines compared to concrete buildings

- Design flexibility for future expansion

- High strength-to-weight ratio

- Predictable costs through prefabrication

- Adaptability to diverse climates

For investors and contractors in Guyana, steel warehouses offer a practical balance between speed, durability, and long-term value.

Quality Control Throughout the Steel Structure Warehouse Guyana Project

Quality assurance is embedded into every stage of the Steel Structure Warehouse Guyana project. This includes:

- Material traceability and inspection

- Welding quality checks

- Dimensional accuracy verification

- Surface treatment confirmation

- Packaging integrity review

Each step is documented to provide transparency and confidence, especially important for overseas clients managing projects remotely.

Delivering More Than Steel: Long-Term Performance

At XTD Steel Structure, delivering a Steel Structure Warehouse Guyana project means more than shipping steel components. It means delivering a building system designed for real-world conditions.

Every project is guided by three principles:

- Precision: Accurate fabrication and strict quality control

- Protection: Materials and packaging designed for harsh environments

- Performance: Structures engineered for long-term operational reliability

These principles ensure that each warehouse performs as intended from the first day of operation.

A Trusted Partner for Steel Structure Warehouse Guyana Projects

The current Guyana warehouse shipment reflects a proven and repeatable approach to overseas steel structure delivery, built on experience rather than assumptions. From the earliest planning stage to final shipment preparation, every decision is made with export performance and on-site reliability in mind.

For this project, galvanized steel was selected specifically to address Guyana’s high-humidity environment, while welding processes followed American standards commonly used in international industrial construction. These technical choices are not made for marketing purposes—they are practical solutions designed to ensure corrosion resistance, structural integrity, and long-term durability once the warehouse is installed and operational.

Beyond materials and welding, factory-controlled fabrication plays a critical role in ensuring quality consistency. All primary frames, secondary members, and connection components are produced under controlled conditions, allowing dimensional accuracy, weld quality, and fit-up to be verified before shipment. This significantly reduces on-site risks, installation delays, and unexpected adjustments—common challenges in overseas projects when quality control is not handled at the source.

Packaging and logistics are treated with the same level of importance. Each component is carefully organized, protected, and labeled to support smooth unloading and efficient installation upon arrival. This attention to detail ensures that what leaves the factory arrives on site in the same condition—ready to perform without compromise. A brief visual overview of this shipment process and project preparation can be seen in our guyana Project

For project owners, developers, and contractors seeking a reliable Steel Structure Warehouse Guyana solution, this project demonstrates what professional steel manufacturing and global delivery should look like in practice—not just on paper. It shows how environmental understanding, international standards, and disciplined execution come together to support long-term project success.

With extensive experience serving international markets and a strong commitment to quality, XTD Steel Structure continues to support industrial projects worldwide. Every warehouse is delivered with a focus on precision, protection, and performance—ensuring steel structures that are built to perform reliably, wherever they are installed.