Steel structure construction projects are widely adopted in industrial, commercial, and infrastructure developments due to their strength, speed of installation, and long-term performance. However, controlling project budgets remains a critical concern for developers, contractors, and investors. Understanding the key factors that influence costs is essential for accurate planning and cost optimization.

Steel construction cost drivers determine how project budgets are formed, adjusted, and managed throughout the construction lifecycle. From raw material pricing to fabrication complexity and site execution efficiency, multiple variables interact to shape the final cost of a steel structure project.

This article explores the primary cost drivers in steel structure construction projects, focusing on material cost, fabrication cost, and other critical elements that impact overall project expenditure.

Understanding Steel Construction Cost Drivers

Steel construction cost drivers refer to the main factors that directly influence the total cost of designing, fabricating, and erecting steel structures. Unlike conventional construction methods, steel projects rely heavily on prefabrication, precise engineering, and coordinated workflows between design teams, fabrication facilities, and site crews. This high level of integration makes cost drivers more visible and measurable—but at the same time more sensitive to market fluctuations, technical decisions, and execution efficiency.

In steel structure construction, costs are not determined by a single element. Instead, they are the result of multiple interrelated components that collectively shape the project budget from concept design to final installation.

These drivers can generally be grouped into several key categories:

Material-related costs

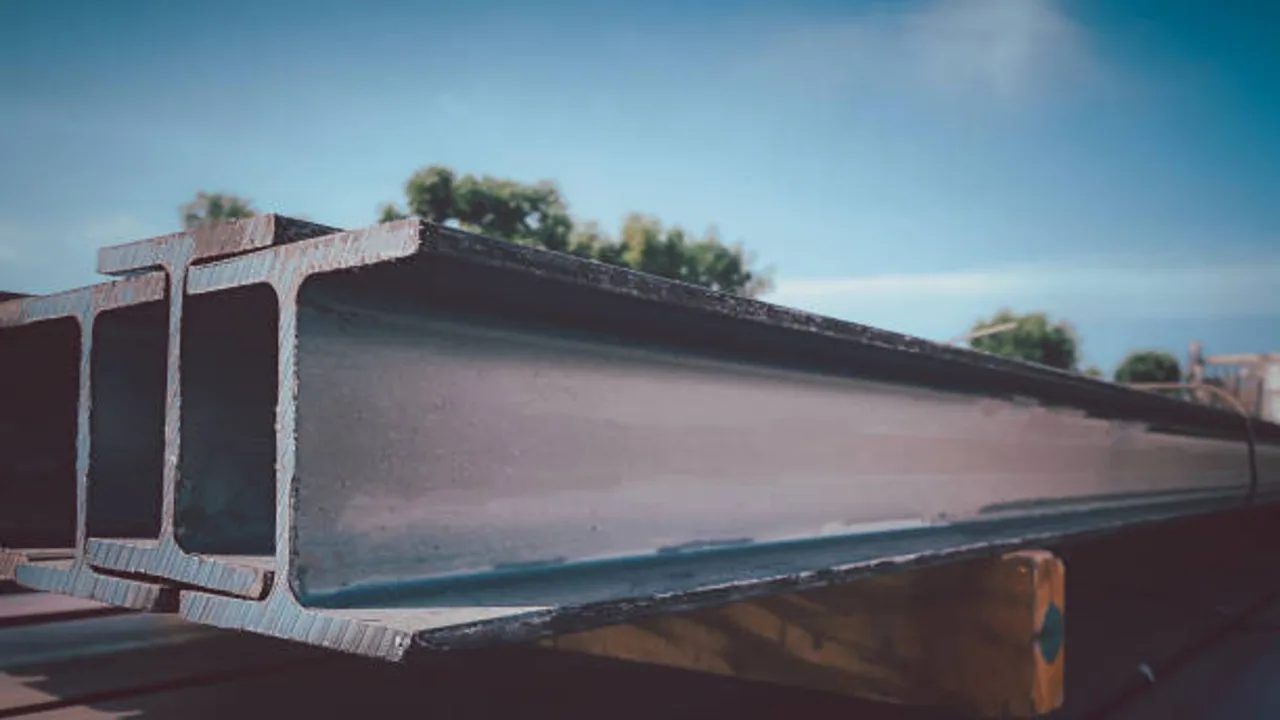

Material cost forms the foundation of any steel construction budget. It includes the price of raw steel, selected steel grades, and surface treatments such as galvanizing or coating. Market volatility, global supply-demand conditions, and material specifications all directly affect this cost category.

Fabrication and manufacturing costs

Fabrication cost reflects the level of processing required to transform raw steel into ready-to-install structural components. Factors such as connection complexity, welding volume, machining precision, quality standards, and production efficiency within the fabrication facility all influence manufacturing expenses.

Transportation and logistics expenses

Steel structures are typically fabricated off-site and transported to the construction location. Transportation costs depend on the distance between the fabrication plant and the site, the size and weight of components, packaging methods, and compliance with local transport regulations. Oversized or modular components can significantly increase logistics planning and delivery costs.

On-site erection and labor costs

Erection cost includes labor, crane usage, lifting equipment, temporary works, and safety measures required during installation. Site conditions, workforce availability, installation speed, and project scheduling constraints all affect this cost driver. Efficient prefabrication and accurate fabrication tolerances can help reduce on-site labor time and associated expenses.

Design complexity and engineering requirements

Engineering decisions play a critical role in cost formation. Long spans, high load requirements, complex geometries, and strict compliance with international standards may increase steel tonnage and fabrication effort. Conversely, optimized structural design can significantly reduce material usage and overall project cost.

A clear understanding of these cost components allows stakeholders to make informed decisions early in the project. By identifying which factors have the greatest cost impact, developers, contractors, and engineers can apply value engineering, optimize design choices, and coordinate procurement and construction strategies to achieve better cost control and predictable project outcomes.

Material Cost as a Primary Cost Driver

Material cost is one of the most significant contributors to steel construction budgets. Steel prices fluctuate based on global supply-demand dynamics, raw material availability, and energy costs.

Key material cost factors include:

- Steel grade and specification

- Market price volatility

- Quantity and weight of steel required

- Surface treatment and corrosion protection

Higher-strength steel grades may reduce structural weight but often come at a premium price. Similarly, projects requiring galvanized or coated steel for harsh environments will incur additional material expenses.

Impact of Market Fluctuations

Global steel prices are influenced by factors such as iron ore availability, energy prices, trade policies, and regional demand. Sudden price increases can significantly affect project budgets if material procurement is not carefully planned.

Early procurement strategies and long-term supplier agreements are commonly used to mitigate material cost risks in large steel structure projects.

Fabrication Cost and Manufacturing Complexity

Fabrication cost represents another major cost driver in steel structure construction. This includes cutting, welding, drilling, assembly, quality control, and surface treatment performed at the manufacturing facility.

Fabrication costs are influenced by:

- Structural complexity and connection details

- Precision and tolerance requirements

- Level of automation in fabrication

- Quality standards and inspection requirements

Projects with complex node connections, curved members, or tight tolerances generally require more labor hours and advanced machinery, increasing fabrication expenses.

Role of Fabrication Efficiency

Efficient production lines, standardized components, and advanced CNC equipment can significantly reduce fabrication time and cost. Choosing an experienced steel structure construction factory with proven manufacturing capabilities often results in better cost control and consistent quality.

Design and Engineering Cost Considerations

Design and engineering decisions directly affect downstream construction costs. Overdesigned structures may increase steel tonnage unnecessarily, while underdesigned systems can lead to costly revisions and safety risks.

Key engineering-related cost drivers include:

- Structural system selection

- Span length and load requirements

- Compliance with local and international standards

- Integration with architectural and MEP systems

Optimized structural design balances safety, performance, and material efficiency, reducing both material and fabrication costs.

Transportation and Logistics Costs

Steel structures are typically fabricated off-site and transported to the construction location. Transportation costs depend on:

- Distance between factory and site

- Component size and weight

- Packaging and handling requirements

- Local transportation regulations

Large or oversized components may require special transport arrangements, permits, or escort vehicles, increasing logistics expenses. Modular design and optimized component sizing can help minimize these costs.

On-Site Erection and Labor Costs

On-site erection costs include labor, equipment rental, temporary works, and safety measures. Steel construction typically benefits from shorter installation periods compared to concrete structures, but costs can still vary significantly.

Key erection cost drivers include:

- Project location and labor availability

- Cranes and lifting equipment requirements

- Site accessibility and working conditions

- Construction schedule constraints

Efficient erection planning and prefabrication accuracy reduce installation time, leading to lower labor and equipment costs.

Project Scale and Scheduling Effects

Larger steel structure projects often benefit from economies of scale, reducing unit costs per ton of steel. However, tight schedules or phased construction requirements can increase costs due to overtime labor, parallel workflows, or expedited fabrication.

Schedule-driven cost increases are common in projects with:

- Fast-track delivery requirements

- Limited on-site storage space

- Concurrent trades and complex coordination

Early schedule alignment between design, fabrication, and erection teams is critical for cost control.

Risk Factors and Contingency Costs

Uncertainty is an inherent part of construction projects. Common risk-related cost drivers include:

- Material price escalation

- Design changes during execution

- Weather disruptions

- Regulatory or inspection delays

Well-managed projects allocate contingency budgets based on risk assessments, helping absorb unexpected costs without compromising project viability.

Strategies to Optimize Steel Construction Costs

Managing steel construction cost drivers requires an integrated approach that aligns design, manufacturing, and site execution.

Effective cost optimization strategies include:

- Early-stage cost planning and value engineering

- Standardization of structural components

- Collaboration with experienced fabrication partners

- Accurate scheduling and logistics planning

By addressing cost drivers holistically, project stakeholders can achieve predictable budgets and improved return on investment.

Conclusion: Managing Cost Drivers for Successful Steel Projects

Steel structure construction offers speed, strength, and flexibility, but its cost performance depends on a clear understanding of key cost drivers. Material cost, fabrication cost, engineering decisions, and execution efficiency all play decisive roles in shaping project budgets.

By identifying and managing these drivers early, developers and contractors can control risks, optimize resources, and deliver steel structure projects that meet both technical and financial objectives.