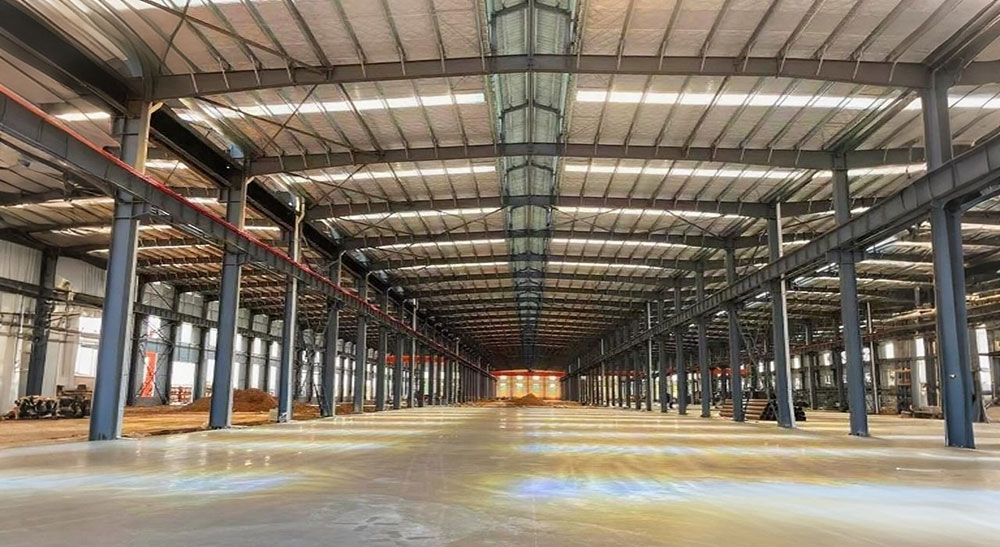

Prefabricated Steel Structure

A modern prefabricated steel structure delivers outstanding efficiency, durability, and construction speed, making it a preferred solution for industrial, commercial, and logistics-based projects. Through factory-controlled production, structural components achieve greater precision, higher consistency, and improved long-term performance compared to traditional on-site construction.

With demand rising for reliable and rapid building systems, developers and contractors are turning to engineered solutions that minimize delays and reduce project risks. A well-designed prefabricated steel building structure supports clean installation, stable load performance, and flexible architectural planning suitable for a variety of building types.

XTD Steel Structure provides integrated engineering and manufacturing services for clients across multiple regions. From workshops to warehouses and office facilities, our prefabricated steel structure building systems offer scalability, energy efficiency, and optimized material usage, helping businesses complete projects with confidence and predictable results.

What We Build

We deliver industrial workshops, logistics facilities, commercial halls, production buildings, agricultural storage, modular offices, and multi-purpose steel facilities—each designed to take advantage of prefabricated assembly for faster site work and dependable structural strength.

As an industry-leading full-process prefab steel building manufacturer, XTD Steel Structure has ploughed deeply into the field of transportation technology facilities for more than 20 years. Relying on the high-performance characteristics of Q355B S355JR A572 SM490A grade high-strength steel, coupled with continuous technological innovation, XTD Steel Structure reconstructs the space of the aviation hubs and provides global customers with a modernized terminal building system that integrates high efficiency and intelligent green building, from the design of the steel structure, processing, manufacturing, construction, to the subsequent maintenance during the use of the building. We create a modernized terminal building system that is highly efficient, intelligent, and green.

In the global exhibition center construction sector, steel structures have emerged as the industry’s preferred solution. As an exhibition center owner, you may currently face the following challenges: traditional concrete buildings typically require 1-2 years of construction time, while pre-booked international convention center might commence as early as next year. You need to strictly control construction budgets while achieving large-span column-free spaces to enhance venue utilization and commercial value. Furthermore, exhibition centers must comply with increasingly stringent green building standards. Steel structure exhibition centers represent the optimal solution to address these pain points. XTD Steel Structure, as a global leader in comprehensive steel construction solutions, delivers modern exhibition center solutions integrating large spans, high flexibility, sustainability, and intelligent features for clients worldwide.

XTD Steel Structure is a prefabricated steel building manufacturer in the field of modular construction, focusing on providing global customers with full-scenario solutions ranging from 30X50 single-story steel factories to multi-story mega plants stretching over several kilometers. With more than 20 years of deep cultivation in the industry, we have successfully delivered thousands of factories and infrastructures, with a cumulative plant construction area of nearly 10 million square meters, setting a benchmark in the field of steel structure construction.

As an innovative leader in the field of global steel structure engineering, XTD Steel Structure gathers the industry’s top R&D team to study the special usage scenarios and functional requirements of gas stations in depth, and customizes high-performance and cost-effective prefabricated steel structure gas station solutions for global customers. The steel structure building adopts a modular design concept, which can split the gas station into several standardized and fast-assembling functional modules, which not only significantly shortens the on-site construction period but also effectively reduces the impact of construction on the surrounding environment.

Our Products

Our products include rigid frame systems, roof and wall cladding panels, modular steel components, braced frames, engineering-grade steel trusses, insulation systems, and building accessories that support thermal performance and long-term durability.

Our Projects

XTD Steel Structure has contributed to numerous workshop expansions, logistics hubs, manufacturing bases, and export-oriented facilities, supplying prefabricated components engineered for precise assembly and stable performance across a wide range of project environments.

Frequently Asked Questions

What advantages does a prefabricated steel structure offer?

It provides faster construction, predictable quality, and reduced on-site labor. A prefabricated steel structure also ensures accurate alignment between components and improved resistance to environmental conditions.

Can prefabricated steel systems be customized?

Yes. Every prefabricated steel building structure can be adjusted for span size, internal layout, façade style, insulation performance, and load requirements.

What industries use prefabricated systems the most?

Yes. Every prefabricated steel building structure can be adjusted for span size, internal layout, façade style, insulation performance, and load requirements.

Do you manufacture structural workshops?

Manufacturing, warehousing, agriculture, logistics, aviation support, and commercial operations frequently choose prefabricated steel structure building solutions due to fast installation and strong reliability.

How does prefabrication improve project schedules?

Absolutely. Our prefabricated steel structure workshop systems are suitable for production lines, machining shops, assembly facilities, and light or heavy industrial applications.

Are prefabricated steel structures cost-effective?

Most fabrication occurs inside a controlled factory environment. This minimizes weather delays and allows multiple phases—manufacturing, site preparation, and logistics planning—to progress simultaneously.

Can these buildings withstand extreme climates?

Yes. Reduced labor, shorter installation time, and minimal material waste make prefabricated systems more economical while offering long-term savings through durability and low maintenance.

Do you support projects inside and outside China?

All structures are engineered for local conditions including wind, snow, seismic loads, and temperature variations, ensuring performance in demanding environments.

Jonathan W.

Chen Y.

Émilie C.

Lucía F.

Omar D.

- +86 138 6251 1010

- [email protected]