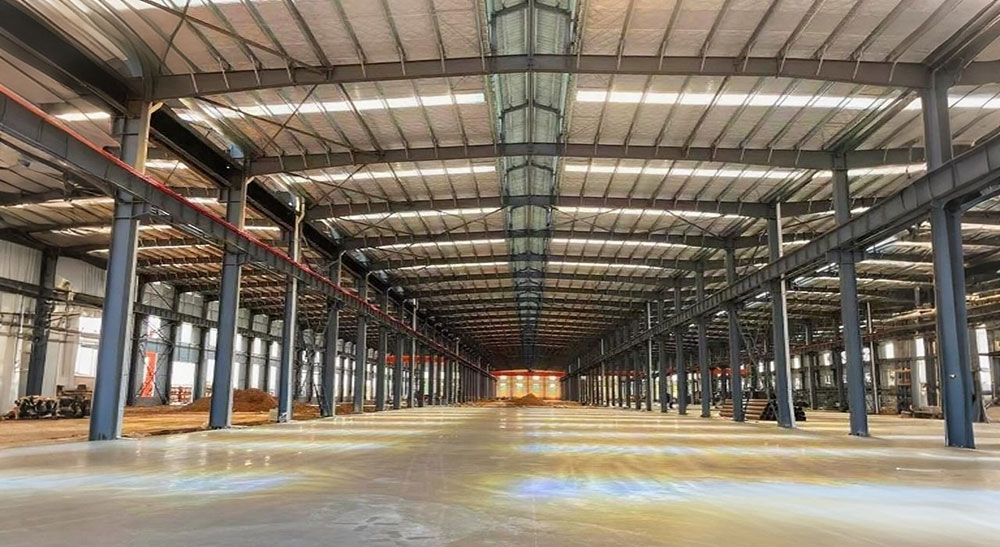

Steel Structure Construction

Modern steel structure construction offers exceptional speed, precision, and durability for industrial and commercial developments. At XTD Steel Structure, we combine advanced engineering with controlled factory fabrication to deliver reliable structural systems for projects of every scale.

Through streamlined workflows and high-accuracy production, our steel structure building construction services ensure stable performance, reduced on-site labor, and efficient installation timelines. Every component is engineered to meet project-specific requirements, environmental loads, and international quality standards.

XTD Steel Structure supports global clients with engineering, fabrication, and delivery services designed for long-term reliability. As a trusted partner in this industry, we help developers, contractors, and operators achieve consistent results throughout the construction cycle.

What We Build

We develop steel structural systems for factories, logistics centers, aviation facilities, commercial buildings, and large infrastructure projects. Each solution is engineered for safety, efficiency, and project-driven performance.

As an industry-leading full-process prefab steel building manufacturer, XTD Steel Structure has ploughed deeply into the field of transportation technology facilities for more than 20 years. Relying on the high-performance characteristics of Q355B S355JR A572 SM490A grade high-strength steel, coupled with continuous technological innovation, XTD Steel Structure reconstructs the space of the aviation hubs and provides global customers with a modernized terminal building system that integrates high efficiency and intelligent green building, from the design of the steel structure, processing, manufacturing, construction, to the subsequent maintenance during the use of the building. We create a modernized terminal building system that is highly efficient, intelligent, and green.

In the global exhibition center construction sector, steel structures have emerged as the industry’s preferred solution. As an exhibition center owner, you may currently face the following challenges: traditional concrete buildings typically require 1-2 years of construction time, while pre-booked international convention center might commence as early as next year. You need to strictly control construction budgets while achieving large-span column-free spaces to enhance venue utilization and commercial value. Furthermore, exhibition centers must comply with increasingly stringent green building standards. Steel structure exhibition centers represent the optimal solution to address these pain points. XTD Steel Structure, as a global leader in comprehensive steel construction solutions, delivers modern exhibition center solutions integrating large spans, high flexibility, sustainability, and intelligent features for clients worldwide.

XTD Steel Structure is a prefabricated steel building manufacturer in the field of modular construction, focusing on providing global customers with full-scenario solutions ranging from 30X50 single-story steel factories to multi-story mega plants stretching over several kilometers. With more than 20 years of deep cultivation in the industry, we have successfully delivered thousands of factories and infrastructures, with a cumulative plant construction area of nearly 10 million square meters, setting a benchmark in the field of steel structure construction.

As an innovative leader in the field of global steel structure engineering, XTD Steel Structure gathers the industry’s top R&D team to study the special usage scenarios and functional requirements of gas stations in depth, and customizes high-performance and cost-effective prefabricated steel structure gas station solutions for global customers. The steel structure building adopts a modular design concept, which can split the gas station into several standardized and fast-assembling functional modules, which not only significantly shortens the on-site construction period but also effectively reduces the impact of construction on the surrounding environment.

Our Products

Our construction systems include rigid frames, steel platforms, architectural steelwork, and long-span structures. These engineered products enhance stability, streamline assembly, and support diverse industrial and commercial applications.

Our Projects

XTD Steel Structure has successfully completed construction projects across transportation hubs, industrial facilities, warehousing complexes, and major public infrastructure—delivering consistent accuracy and long-term reliability.

Frequently Asked Questions

What makes steel structure construction faster than traditional methods?

Steel construction relies on prefabricated components produced in a controlled environment, which minimizes on-site work. Our steel structure construction approach reduces delays, enhances accuracy, and shortens overall project schedules compared to concrete.

Is steel suitable for building large industrial facilities?

Yes. The engineering flexibility of steel structure building construction makes it ideal for large-span factories, production halls, aviation facilities, and logistics centers. Steel allows greater design freedom and stronger load-bearing performance.

Do you offer full engineering and fabrication support?

Yes. The engineering flexibility of steel structure building construction makes it ideal for large-span factories, production halls, aviation facilities, and logistics centers. Steel allows greater design freedom and stronger load-bearing performance.

What are the advantages of factory-produced steel components?

Absolutely. As a professional steel structure construction company, we provide complete services including structural design, fabrication, quality inspection, and delivery with detailed assembly drawings.

Do you supply steel structures for overseas projects?

A steel structure construction factory ensures precise manufacturing, reduced material waste, uniform quality, and improved project efficiency. Controlled fabrication also improves safety and long-term structural reliability.

Can steel construction help reduce project costs?

Yes. XTD Steel Structure exports engineered systems for international developments and provides installation support. Our china construction steel structure solutions are designed to meet global standards.

Is steel construction environmentally friendly?

In many cases, yes. Prefabricated steel components reduce labor hours, shorten construction schedules, and minimize rework—helping lower overall project expenditure while improving performance.

Can the construction system be customized?

Steel is recyclable, reduces construction waste, and supports energy-efficient building design. This makes steel structure construction a sustainable option for modern industrial and commercial projects.

Jacob L.

Ali M.

Luis H.

Richard B.

Andrew R.

- +86 138 6251 1010

- [email protected]