Steel factories play a critical role in the global construction and manufacturing supply chain. As demand for faster project delivery and cost control continues to rise, improving production efficiency has become a strategic priority for steel manufacturers. Efficient operations not only reduce lead times but also enhance quality consistency and overall competitiveness.

Steel factory efficiency refers to how effectively a factory converts raw materials into finished steel components using optimized processes, skilled labor, and advanced technology. From workflow design to automation and digital control, multiple factors influence how efficiently a steel factory operates.

This article explores how modern steel factories improve production efficiency, with a focus on workflow optimization, automation, and practical strategies that drive higher output with lower waste.

Understanding Steel Factory Efficiency

Steel factory efficiency measures how well production resources—labor, equipment, materials, and time—are utilized throughout the manufacturing process. In steel fabrication, efficiency directly impacts delivery schedules, fabrication cost, and structural quality.

Unlike traditional workshops, modern steel factories operate as integrated production systems. Each stage, from material cutting and welding to assembly and surface treatment, is interconnected. Any inefficiency in one stage can disrupt the entire production line.

Key objectives of improving steel factory efficiency include:

- Reducing production cycle time

- Minimizing material waste and rework

- Improving labor productivity

- Ensuring consistent fabrication quality

Workflow Optimization in Steel Factories

Workflow design is one of the most influential factors in steel factory efficiency. A well-structured workflow ensures smooth material movement and eliminates unnecessary handling or waiting time between processes.

Process Sequencing and Layout Planning

Efficient factories arrange workstations based on logical production sequences. Cutting, drilling, welding, and assembly areas are positioned to minimize material transport distance and avoid bottlenecks.

Optimized layouts reduce:

- Idle time between processes

- Material handling errors

- Congestion on the shop floor

Standardized Work Procedures

Standard operating procedures ensure that tasks are performed consistently across shifts and teams. Clear work instructions improve efficiency by reducing variation and preventing mistakes that lead to rework.

Automation as a Key Efficiency Driver

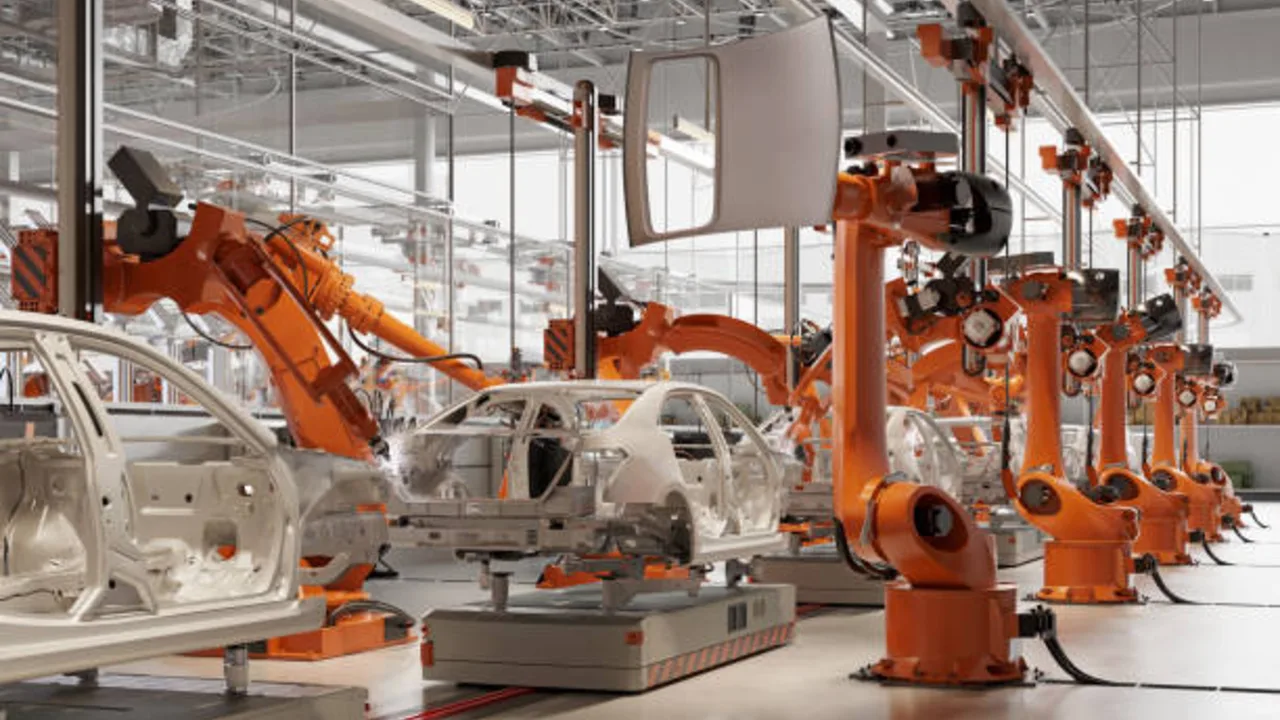

Automation has become a cornerstone of high-efficiency steel factories. Automated systems improve speed, accuracy, and repeatability across fabrication processes.

Automated Cutting and Drilling

CNC cutting lines and drilling machines enable precise processing of steel components with minimal manual intervention. Automation shortens processing time and ensures dimensional accuracy.

Robotic Welding Systems

Robotic welding improves weld quality consistency while reducing dependence on manual labor. Automated welding systems operate continuously and deliver uniform results, especially for repetitive components.

Material Handling Automation

Automated conveyors, cranes, and transfer systems streamline material flow between workstations. This reduces manual handling, improves safety, and accelerates production throughput.

Digital Management and Production Control

Modern steel factories increasingly rely on digital tools to enhance efficiency, accuracy, and operational transparency. As production volumes grow and project schedules become tighter, manual coordination alone is no longer sufficient to manage complex fabrication workflows. Digital management systems bridge this gap by connecting design, planning, and execution into a unified production environment.

Production management software integrates design data, production schedules, material tracking, and inventory control into a single digital platform. This integration allows steel factories to move away from fragmented spreadsheets and manual reporting toward real-time, data-driven decision-making.

Integration of Design Data with Production

One of the key advantages of digital production control is the direct link between engineering models and shop-floor operations. Digital systems synchronize structural drawings, CNC files, and fabrication instructions with production schedules, ensuring that design updates are accurately reflected in manufacturing activities.

Real-Time Production Tracking and Visibility

Digital systems enable real-time monitoring of production status across all fabrication stages. Managers can track progress at each workstation, identify completed tasks, and detect delays as they occur rather than after problems escalate.

Improved Coordination Between Departments

Steel factory operations involve close collaboration between engineering, procurement, production, quality control, and logistics teams. Digital management platforms improve coordination by providing shared access to production data and schedules.

Early Identification of Errors and Delays

Digital production control systems are designed to flag deviations from planned schedules or quality standards at an early stage. Automated alerts notify managers of potential issues such as missed milestones, material shortages, or quality non-conformities.

Accurate Production Planning and Forecasting

Digital tools improve production planning by combining historical data with real-time performance metrics. This allows factories to forecast capacity, balance workloads, and plan resources more accurately.

Skilled Workforce and Training

While automation improves speed and consistency, skilled workers remain essential to steel factory efficiency. Well-trained operators can quickly adapt to new technologies and troubleshoot issues before they escalate.

Key workforce-related efficiency factors include:

- Technical training for equipment operation

- Cross-functional skills across fabrication stages

- Strong quality awareness

A knowledgeable workforce complements automation by maximizing equipment utilization and minimizing downtime.

Quality Control and Rework Reduction

Defects and rework significantly reduce production efficiency. Efficient steel factories integrate quality control directly into the production process rather than relying solely on final inspections.

Preventive quality measures include:

- In-process inspections

- Dimensional checks at key stages

- Weld quality monitoring

Early detection of issues prevents costly rework and keeps production schedules on track.

Role of Factory Design and Infrastructure

The physical design of a steel factory influences long-term efficiency. Adequate space, overhead crane systems, and optimized production zones enable smooth operations.

Well-designed facilities supporting factory steel structure solutions provide:

- Better material flow

- Higher production capacity

- Improved safety conditions

Infrastructure investments often deliver long-term efficiency gains that outweigh initial costs.

Continuous Improvement and Lean Manufacturing

Leading steel factories adopt continuous improvement principles to maintain efficiency over time. Lean manufacturing techniques focus on eliminating waste, optimizing workflow, and improving value creatio